Large-section crystallizer automatic slag adding machine

A technology for automatic slag feeding and moulding, which is applied in the field of automatic slag feeding devices for continuous casting machine moulds, and can solve the problems of large operation interference, limited adjustment range of slag outlet, and inapplicability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

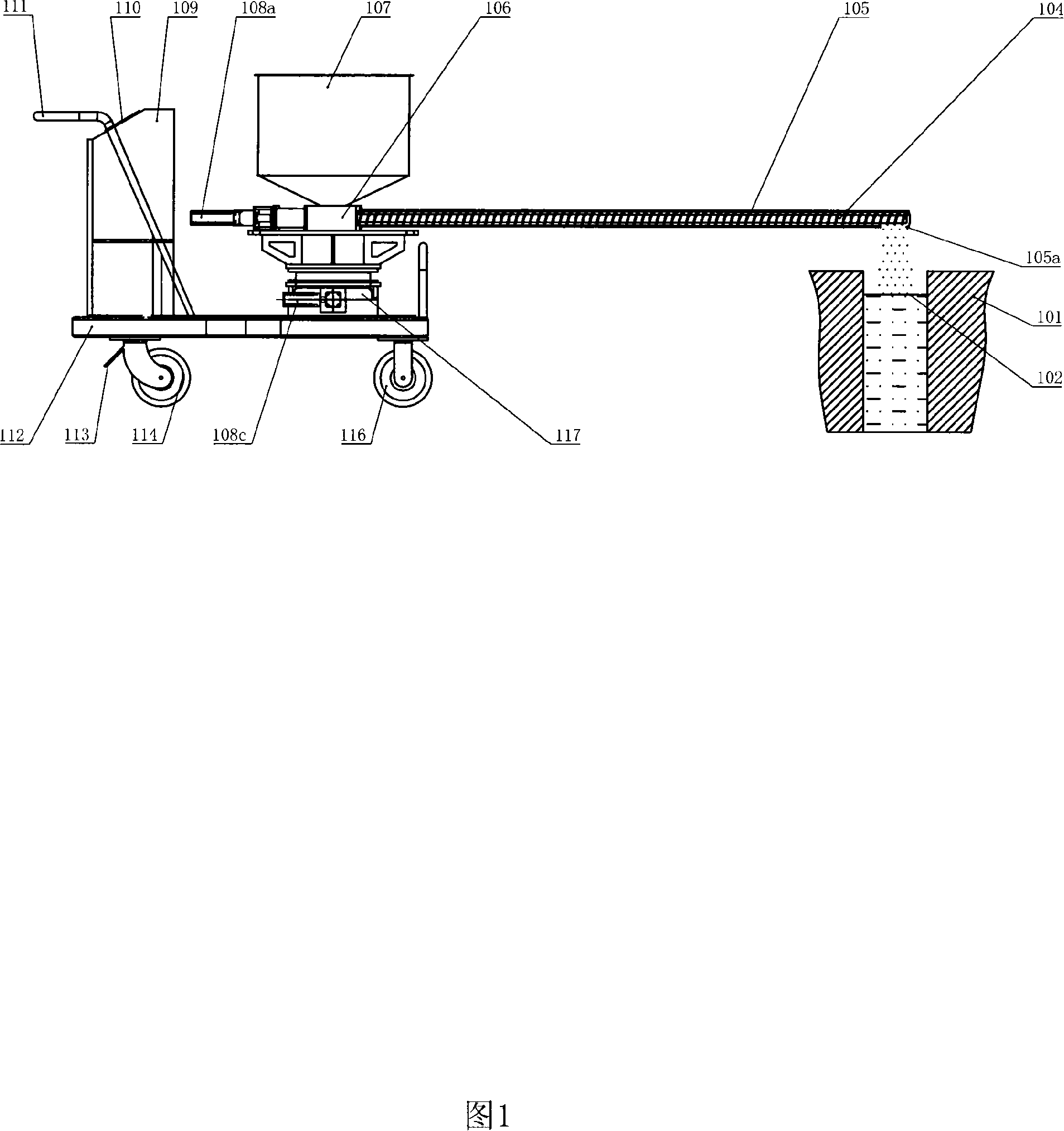

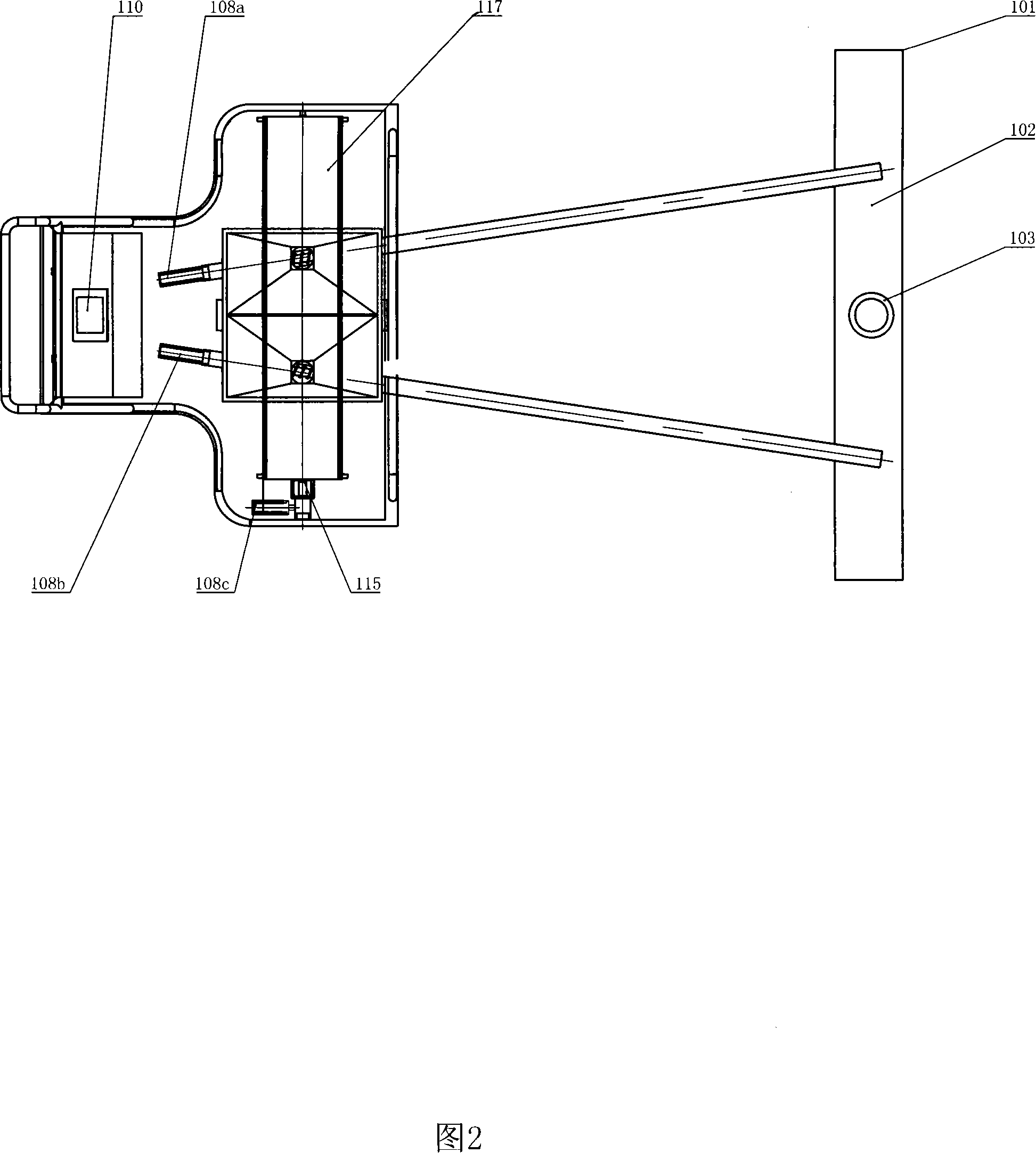

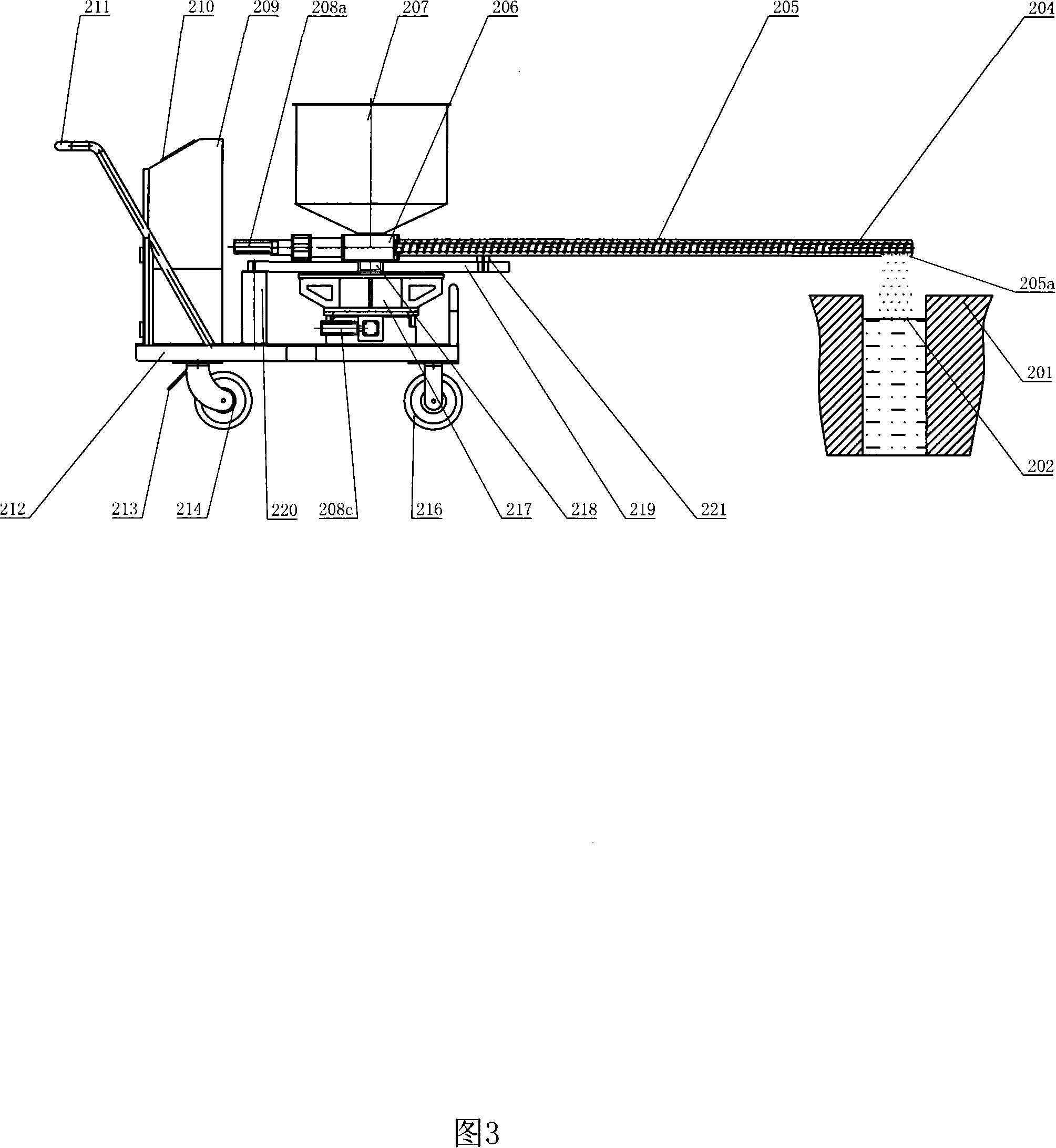

[0016] The first embodiment of the present invention is shown in Fig. 1 and Fig. 2 . The movable trolley (112) loaded with the slag adding device is pushed to the center of the inner arc casting platform of the crystallizer (101) close to the crystallizer (101) by the handrail (11), and the trolley (112) is braked by foot (13) position. Curved wheels (14) and straight wheels (116) are arranged below the dolly to facilitate the movement and direction change of the dolly. The motor (108c) on the trolley (12) drives the transmission screw (15) to rotate, and the nut pair of the transmission screw (115) drives the translation device (117) and the slag bucket (107) on it to move together. There are 2 collecting ports (106) below the slag hopper (107), and the 2 slag feeding pipes (105) connected to the collecting ports are respectively obliquely extended to both sides of the nozzle (103) of the crystallizer, which can shorten the slag hopper ( 107) length. The slag feeding port ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com