Electric resistance array touch screen

A resistive array and touch screen technology, which is applied in the direction of electrical digital data processing, instrumentation, data processing input/output process, etc., can solve problems such as limiting the application of resistive touch screens, not supporting multi-point touch, etc., to avoid voltage jitter, high resolution rate, the effect of increasing the utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

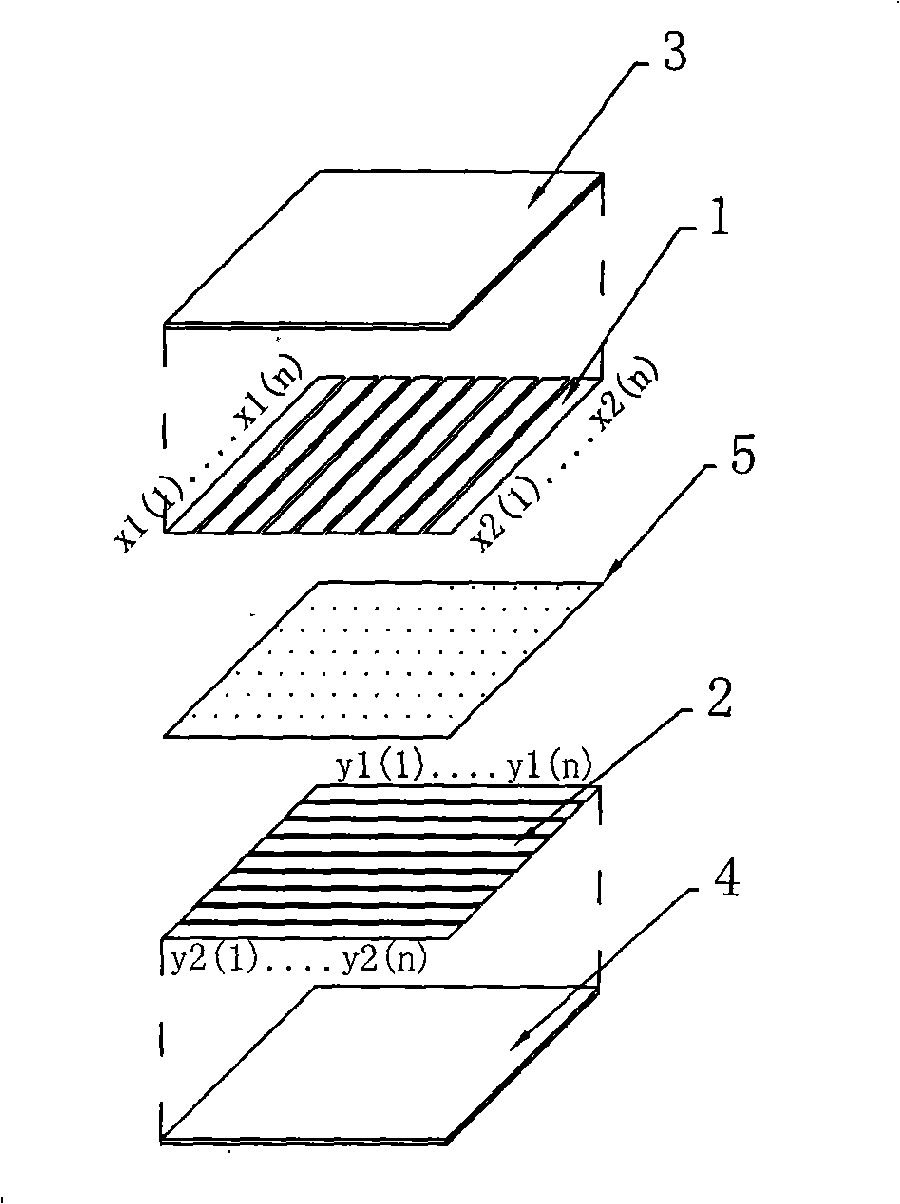

[0038] A resistive array touch screen, including a controller and a touch screen body, the touch screen body includes a detection layer and a working layer, a transparent insulating dot layer 5 is between the detection layer and the working layer, and the detection layer includes a transparent conductive film detection layer 1, The first layer of transparent conductive film detection includes a plurality of detection units, each detection unit is independent and insulated from each other, each detection unit forms a detection electrode for determining the touch point, and the working layer includes a transparent conductive film that cooperates with the detection electrodes The resistive working layer 2, the transparent conductive film resistive working layer 2 forms a resistive working unit.

[0039] The detection layer and the working layer are mutual detection layers. For example, the detection layer also includes a plastic film layer 3, and the transparent conductive film d...

Embodiment 2

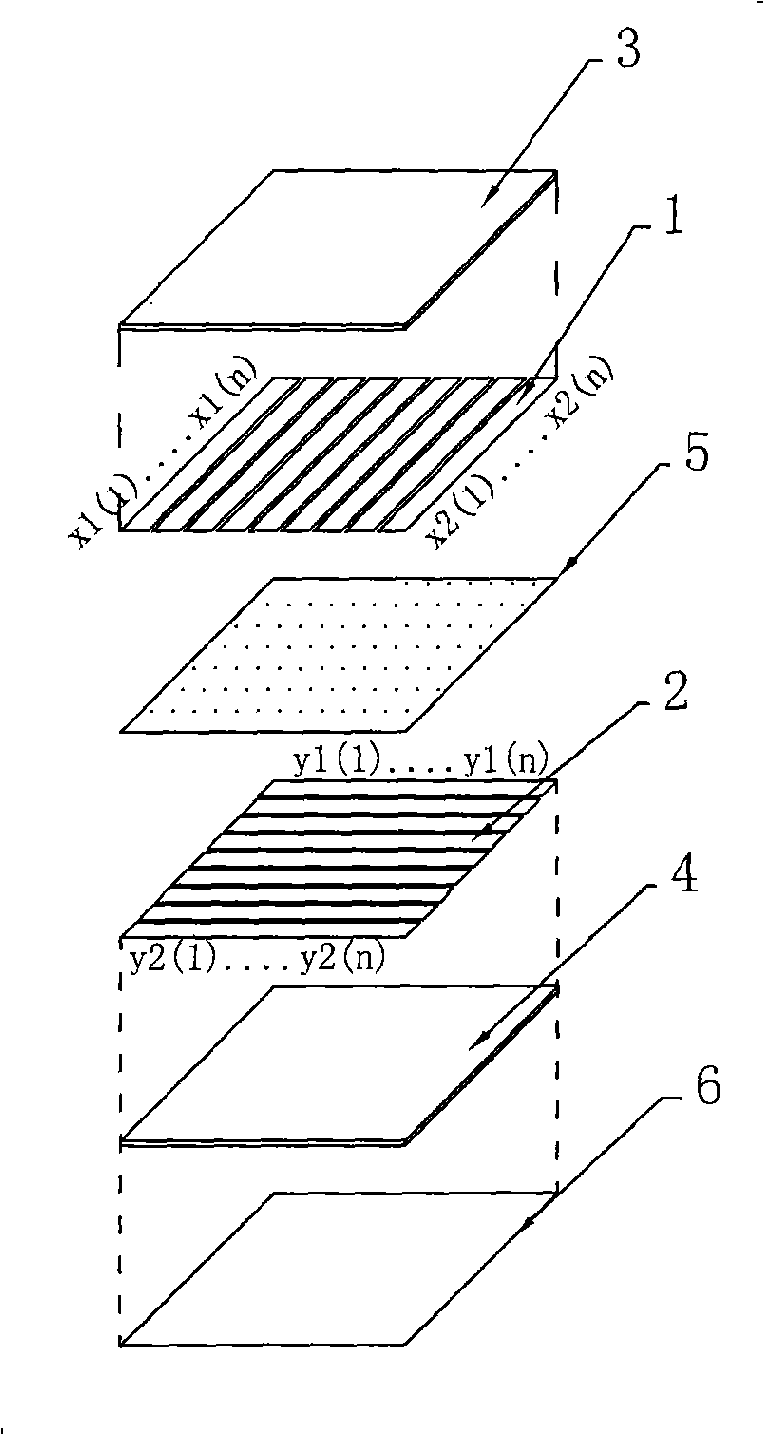

[0050] A resistive array touch screen, including a controller and a touch screen body, the touch screen body includes a detection layer and a working layer, a transparent insulating dot layer 5 is between the detection layer and the working layer, and the detection layer includes a transparent conductive film detection layer 1, The transparent conductive film detection layer 1 includes a plurality of detection units, each detection unit is independent and insulated from each other, and each detection unit forms a detection electrode for determining a touch point, and the working layer includes a transparent conductive film that cooperates with the detection electrodes The resistive working layer 2, the transparent conductive film resistive working layer 2 forms a resistive working unit.

[0051] The detection layer and the working layer are mutual detection layers. For example, the detection layer also includes a plastic film layer 3, and the transparent conductive film detect...

Embodiment 3

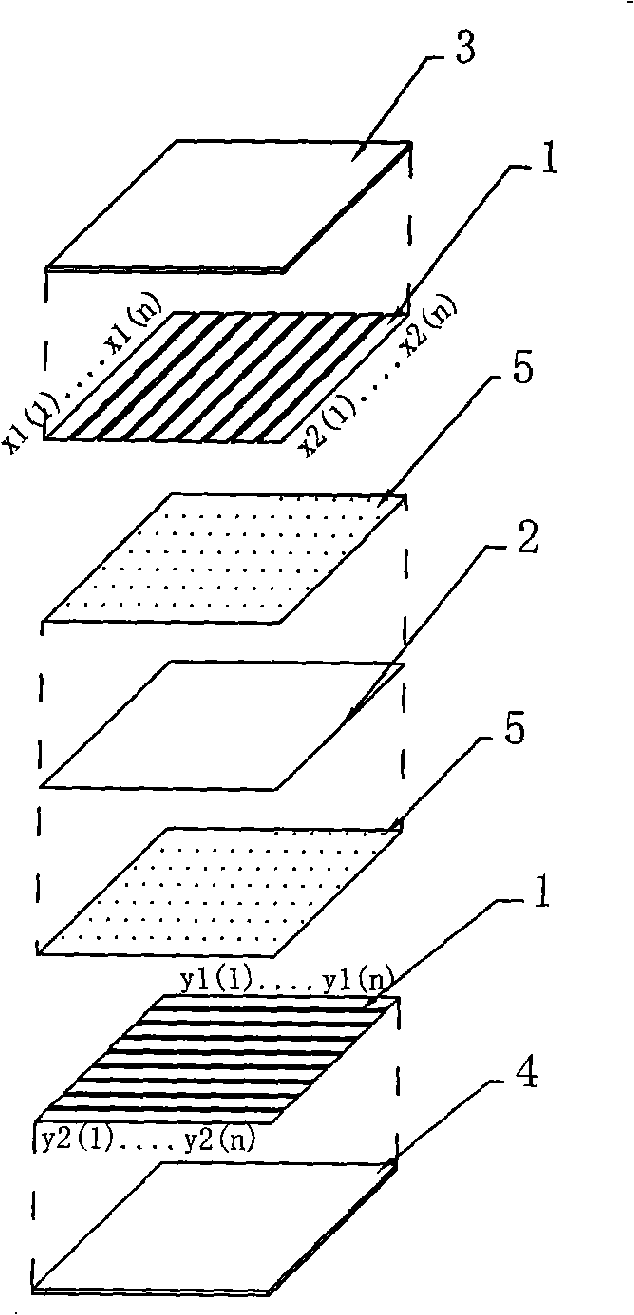

[0061] A resistive array touch screen, including a controller and a touch screen body, the touch screen body includes a detection layer and a working layer, a transparent insulating dot layer 5 is between the detection layer and the working layer, and the detection layer includes a transparent conductive film detection layer 1, The transparent conductive film detection layer 1 includes a plurality of detection units, each detection unit is independent and insulated from each other, and each detection unit forms a detection electrode for determining a touch point, and the working layer includes a transparent conductive film that cooperates with the detection electrodes The resistive working layer 2, the transparent conductive film resistive working layer 2 forms a resistive working unit.

[0062] The detection layer includes an upper detection layer and a lower detection layer. The upper detection layer includes a plastic film layer 3 and a transparent conductive film detection ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com