Excrement bio-separation sampler

A bio-separation and sampler technology, applied in the field of medical equipment, can solve problems such as pollution, environmental pollution, and insufficient airtightness when used, and achieve the effect of avoiding environmental pollution and carrying pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

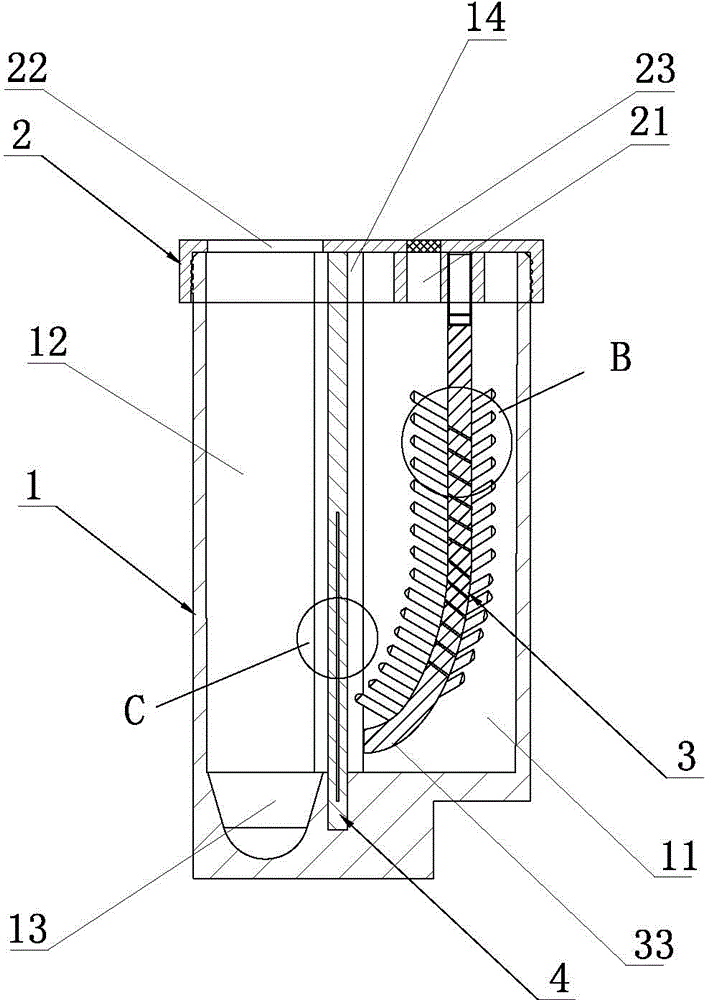

[0029] Such as Figure 1 to Figure 5 As shown, a kind of stool bioseparation sampler of the present invention comprises cup body 1, and described cup body 1 is connected with cup cover 2, and described cup cover 2 is connected with strip sampler 3, and described strip sampler 3 Several sampling barbs 31 are provided, and the inner cavity of the cup body 1 is provided with a filter partition 4, and the filter partition 4 divides the inner cavity into a dilution chamber 11 and a sampling chamber 12, and the inside of the filter partition 4 is set There is a filter screen 41, and the dilution chamber 11 and the sampling chamber 12 are connected to each other through the filter screen 41; the strip sampler 3 is arranged inside the dilution chamber 11; the cup cover 2 is provided with a dilution injection hole 21 And sampling hole 22, described dilution injection hole 21 is positioned at the top of dilution cavity 11, and described sampling hole 22 is positioned at the top of sampl...

Embodiment 2

[0041] The difference between this embodiment and Embodiment 1 is that the first isolation layer is a waterproof and breathable film, and the waterproof and breathable film can also play a breathable role, so that it can be discharged from the sampling chamber 12 during the process of adding diluent. The air in the upper part makes the diluent filling process go smoothly. On the other hand, the waterproof and air-permeable film is convenient for the puncture of the sampling needle, and absorbs the liquid to be tested.

[0042] The rest of this embodiment is the same as Embodiment 1, and will not be repeated here.

Embodiment 3

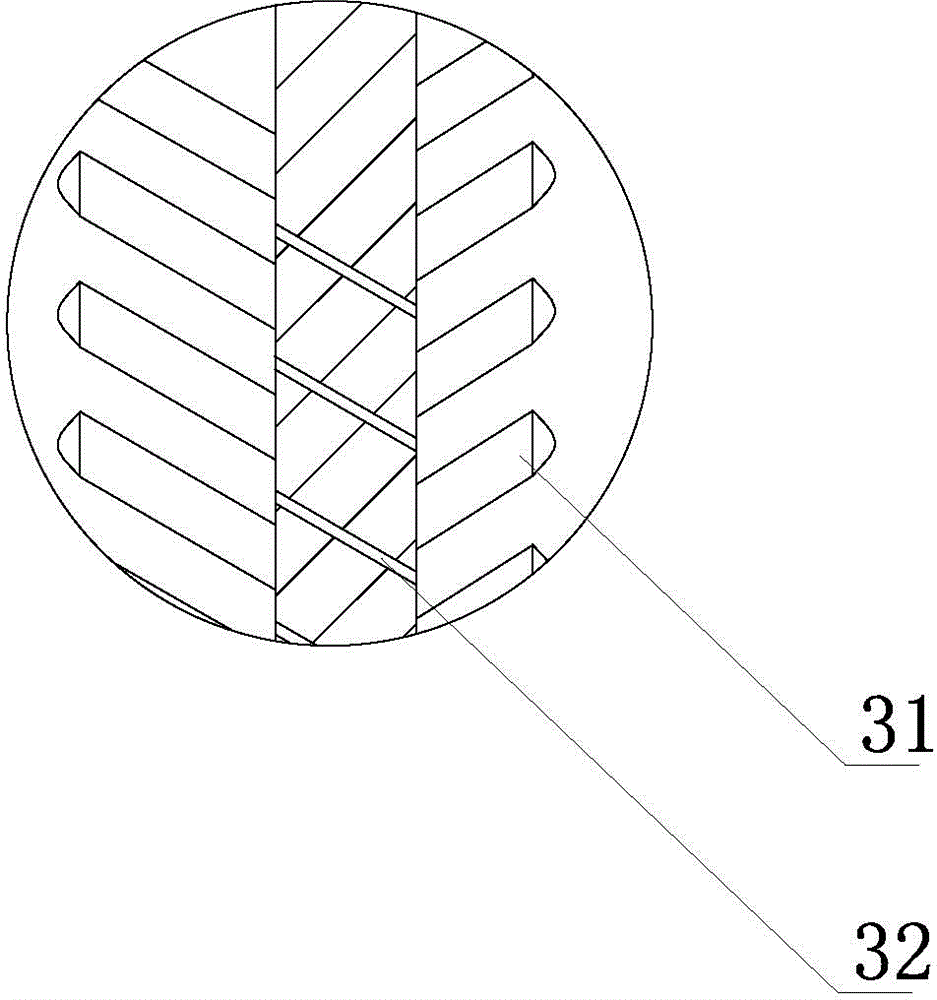

[0044] Such as figure 2 As shown, the difference between this embodiment and Embodiment 1 lies in that: the strip sampler 3 is provided with a sampling through hole 32 , and the sampling through hole 32 and the sampling barb 31 are staggered from each other. The belt sampler 3 of this embodiment is provided with a sampling through hole 32, so that the belt sampler 3 is suitable for sampling thinner feces, which cannot be bonded to the barbs 31 due to poor viscosity. The setting of the sampling through hole 32 can well make up for this situation, because the thinner feces are liquid, and the liquid feces can be adsorbed in the inside of the sampling through hole 32, so the strip sampler 3 with the sampling through hole 32 can be completed. Sampling of thinner stools.

[0045] In addition, the sampling through hole 32 can have the above-mentioned functions, and it is also convenient for the diluent to wash out the feces sample of the strip sampler 3. The through hole 32 can s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com