A spherical particle multi-point contact test device and its loading method

A spherical particle, test device technology, applied in measuring device, using stable tension/pressure test material strength, instrument, etc., can solve the problem of inability to meet the needs of use, achieve simple operation, accurate test results, repeatability high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

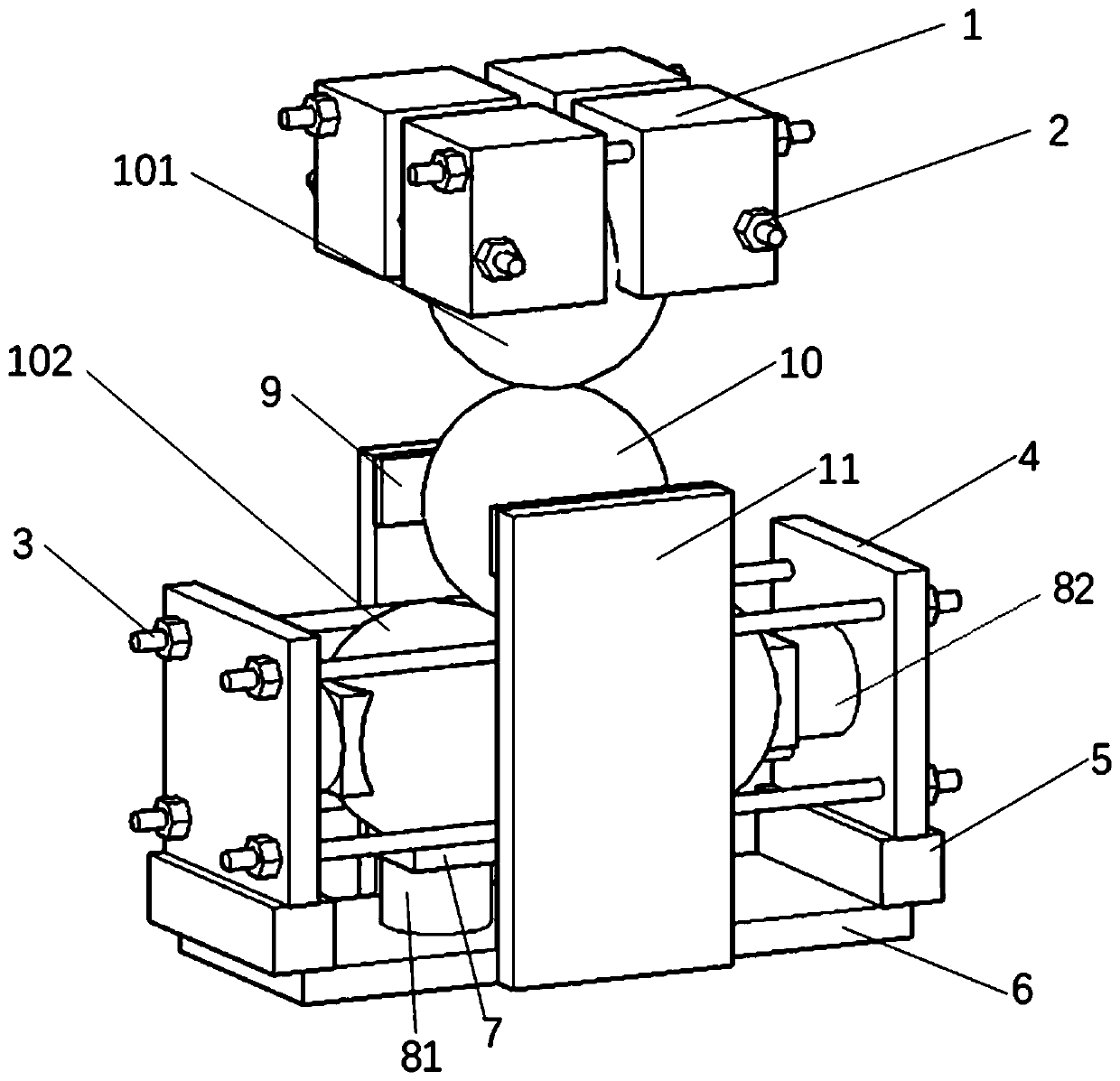

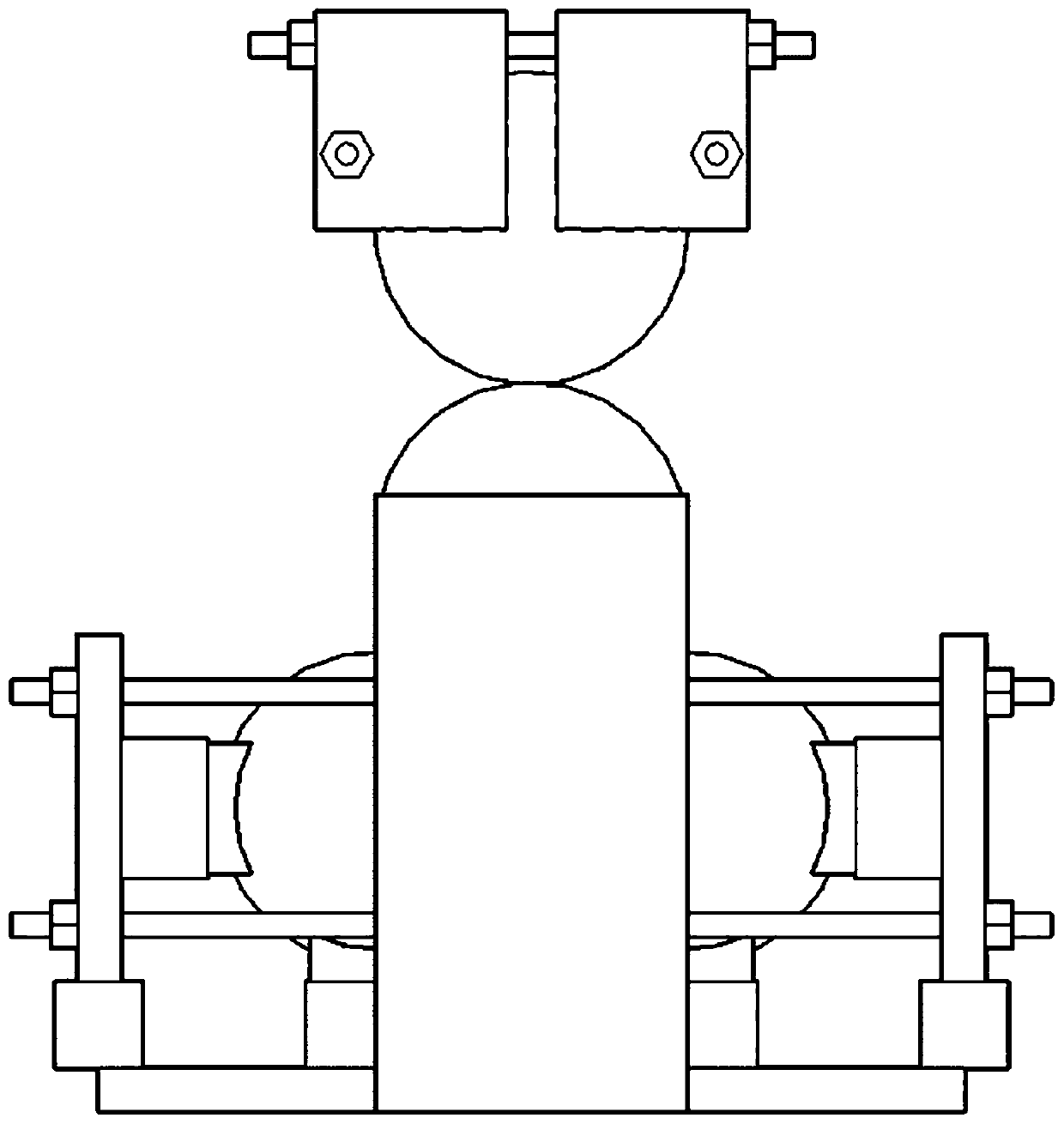

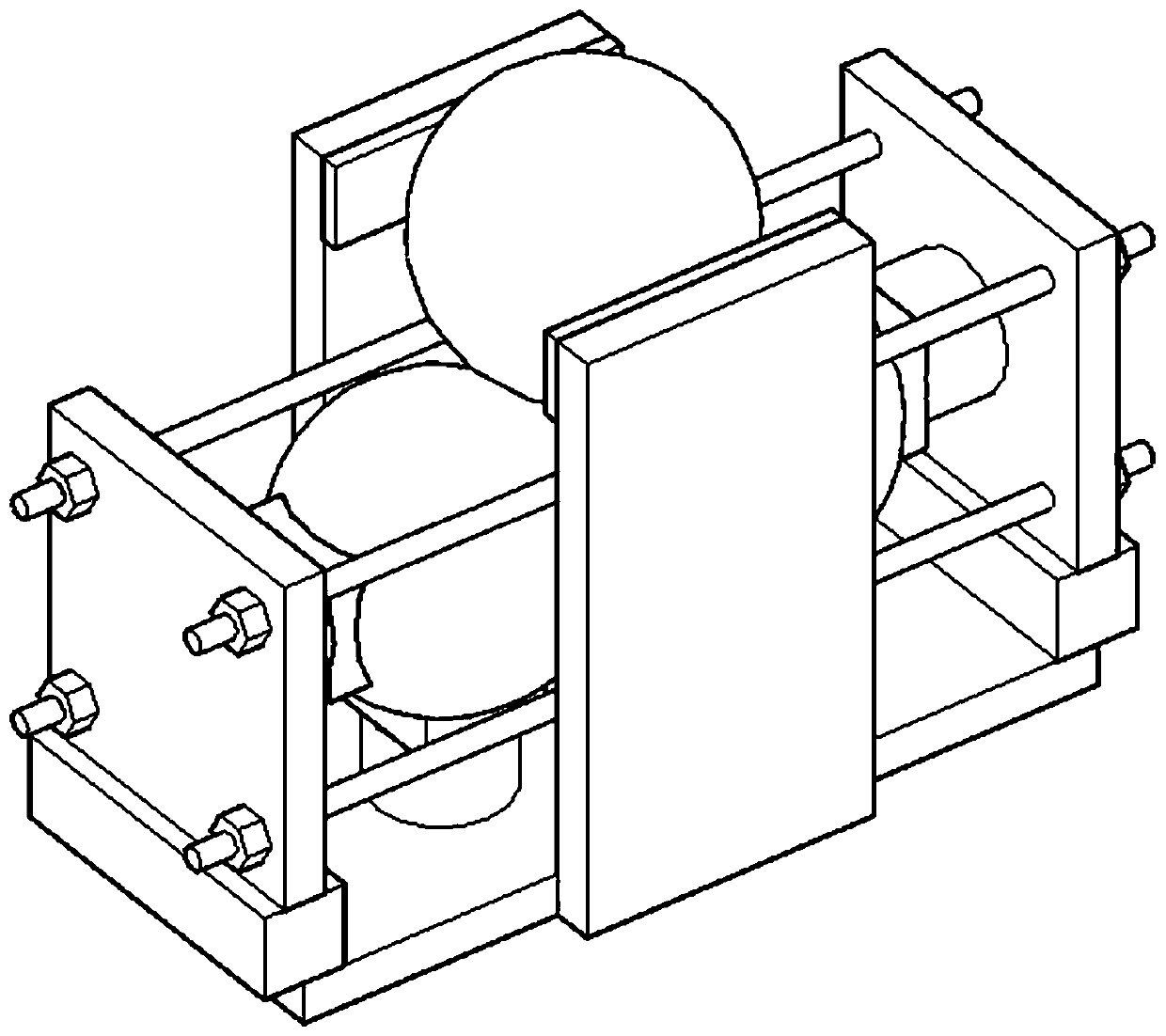

[0030] Such as Figure 1-4 As shown, the present invention provides a multi-point contact test device for spherical particles that can measure the contact point force based on a biaxial rheometer. The test device is divided into upper and lower parts, and the upper part is a single-ball restraint fixture. Placed in four spherical confinement blocks 1 with spherical depressions and constrained by four cap bolts 2;

[0031] The lower device includes two parts: a multi-sphere restraint fixture and a measuring assembly, wherein the multi-sphere restraint fixture is fixed by two rigid baffles 4 through four parallel stud bolts 3 to fix the parallel lower spherical particles 102, the lower spherical particles 102 and A baffle pressure sensor 82 is placed between the left and right rigid baffles 4, a limited displacement spacer 7 is placed between the lower spherical particle 102 and the baffle pressure sensor 82, and the fixed rigid baffle 4 is placed on the front and rear with the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com