Cement decomposing furnace temperature control method based on constraint smith GPC

A temperature control method and generalized predictive control technology, which is applied in the direction of temperature control, adaptive control, general control system, etc. by using electric methods, can solve the problem that PID control is difficult to obtain the control effect, it is difficult to effectively reflect the dynamic characteristics of the object, and the amount of calculation is difficult. Major and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

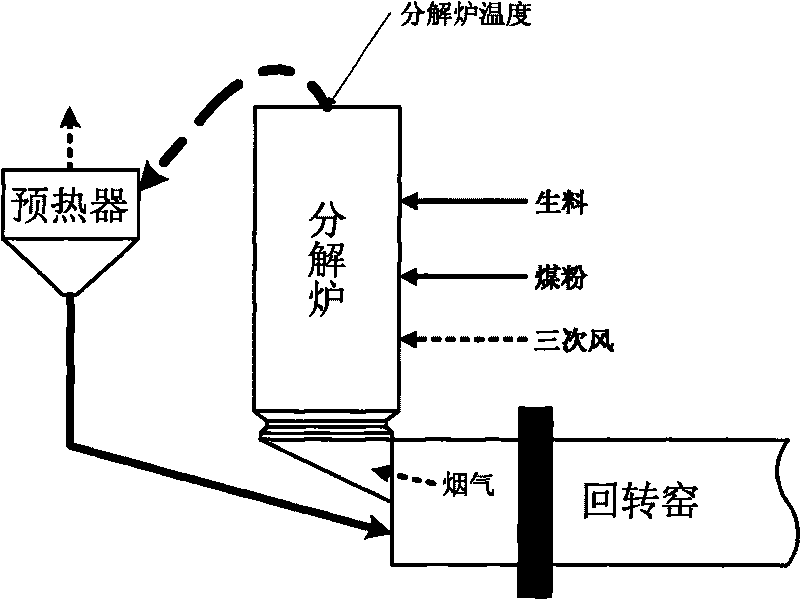

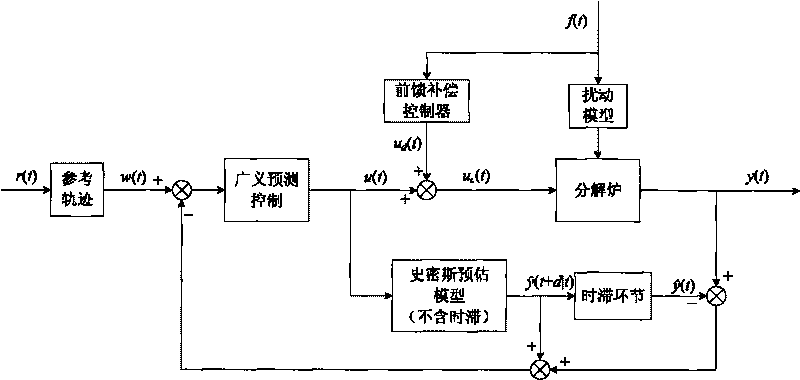

[0036] The present invention is based on the cement calciner temperature control method of constraint Smith's generalized predictive control and comprises the following steps:

[0037] Variable selection: select the pulverized coal flow rate as the control variable, the raw flow rate as the feed-forward variable, and the calciner temperature as the controlled variable;

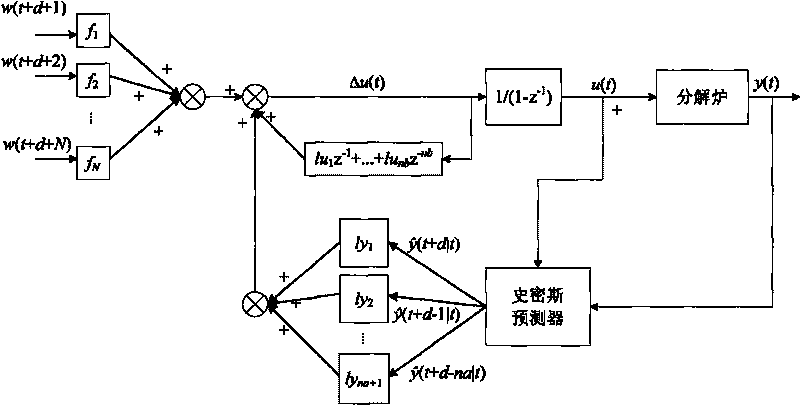

[0038] Model identification: Aiming at the control channel between the pulverized coal flow rate and the calciner temperature and the disturbance channel between the raw material flow rate and the calciner temperature, based on the model identifier combining the least square method and the lag time estimation method, the cement model is obtained by using the learning data. Pulse transfer function model of calciner control channel and disturbance channel;

[0039] Optimal calculation: at the current time t, using the past input and output information and predicted future input information, the pulse transfer fu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com