Steel plate rust removing mechanism

A technology of steel plate and collecting mechanism, which is applied in the direction of grinding frame, grinding slide plate, grinding machine tool parts, etc., can solve the problems of potential safety hazards, work fatigue, physical exertion, etc., achieve a wide range of use and improve friction , the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

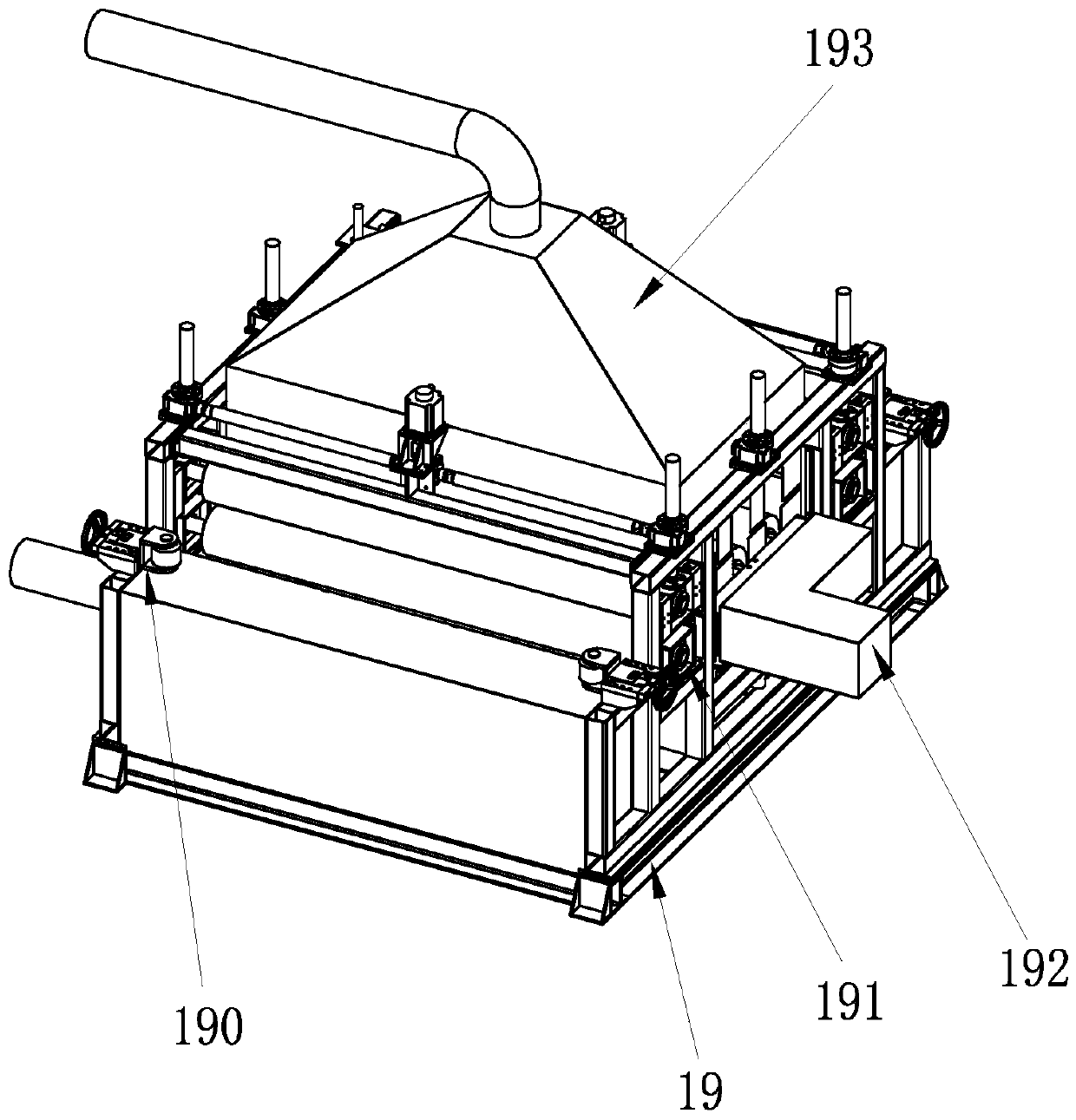

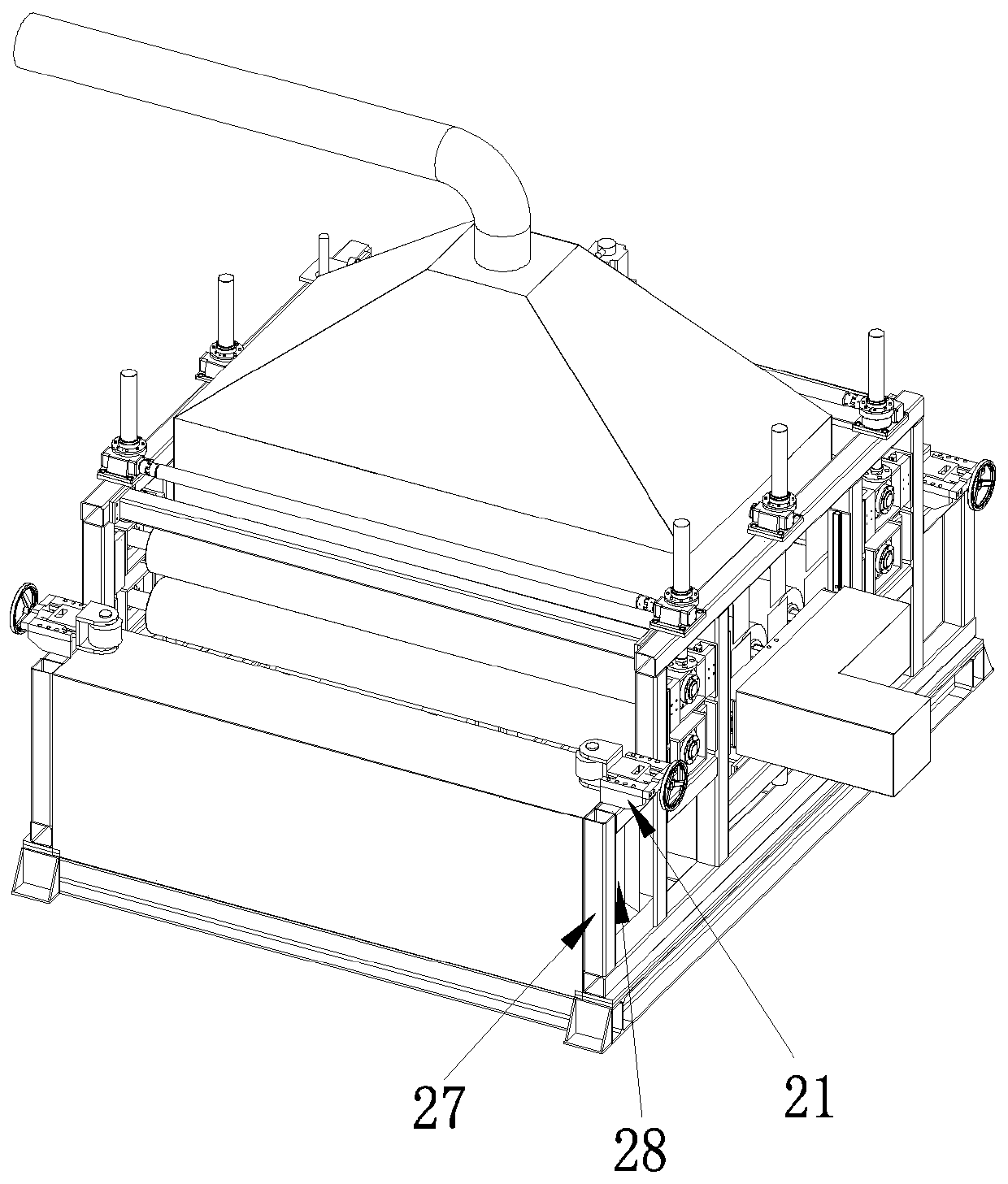

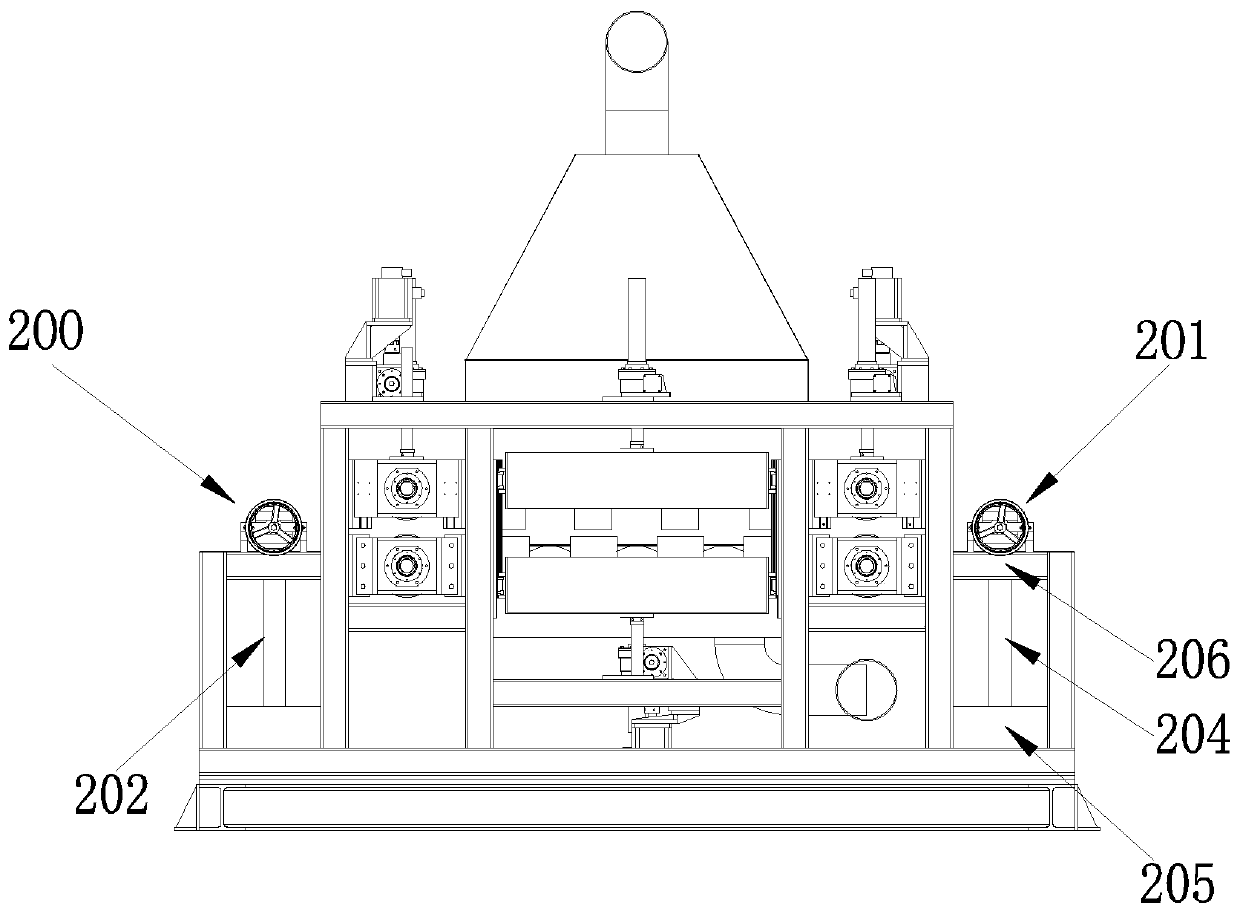

[0041] Example: such as Figure 1-4 As shown, a steel plate derusting mechanism includes a fixed platform 19, a steel plate guiding device 190 arranged on the fixed platform 19, a steel plate conveying positioning device 191, a steel plate derusting device 192 and a steel plate derusting and dust removing device 193; The steel plate guide 190 comprises a front guide mechanism 200 and a rear guide mechanism 201 which are arranged oppositely on the fixed platform 19. The front guide mechanism 200 comprises guide blocks 21 arranged symmetrically on the left and right sides of the fixed platform 19. There is a slider 26, one end of the slider 26 is connected with a guide screw 22, the outer end of the guide screw 22 is connected with a guide handwheel 23, and the other end of the slider 26 is fixed with a guide plate 24 in a "U" shape. The guide wheel 25 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com