Planar screw synchronizer

A synchronizer and screw technology, which is applied in the field of mechanical assembly tooling, can solve the problems of scratches, bumps, and low efficiency of parts, and achieve the effects of avoiding scratches and bumps, liberating manpower, and avoiding collisions and scratches

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with the accompanying drawings and embodiments, but not as a basis for limiting the present invention.

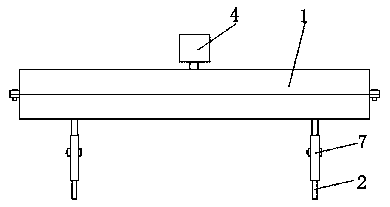

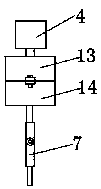

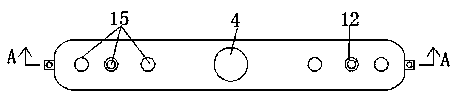

[0029] Example. A planar screw synchronizer, constituted as Figure 1-7 As shown, a housing 1 is included, and a driving assembly is arranged in the housing 1, and the driving assembly connects two driven assemblies; the driven assembly includes a screwdriver head 2 . The drive assembly can drive the screwdriver bits 2 of the two driven assemblies to rotate simultaneously and in the same direction, so as to realize the assembly or disassembly of the two screws on the end cover.

[0030] The driving assembly includes a driving pulley 3 connected to the motor 4 ; the driven assembly includes a driven pulley 5 connected to the driving pulley 3 through a belt 6 . After the motor 4 is started, the driving pulley 3 is driven to rotate, and the driving pulley 3 drives two driven pulleys 5 to rotate throu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com