Continuous equal channel angular extrusion combination mould and extrusion method

A technology of equal-diameter angular extrusion and combined dies, which is applied in the field of radial-angle extrusion dies and deformation of radial-angle extrusion, which can solve problems such as complex process, inability to provide back pressure, and not involving the realization of extrusion corners, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in more detail below with examples in conjunction with the accompanying drawings. The technical solution of the present invention is not limited to the specific embodiments listed below, but also includes any combination of the specific embodiments.

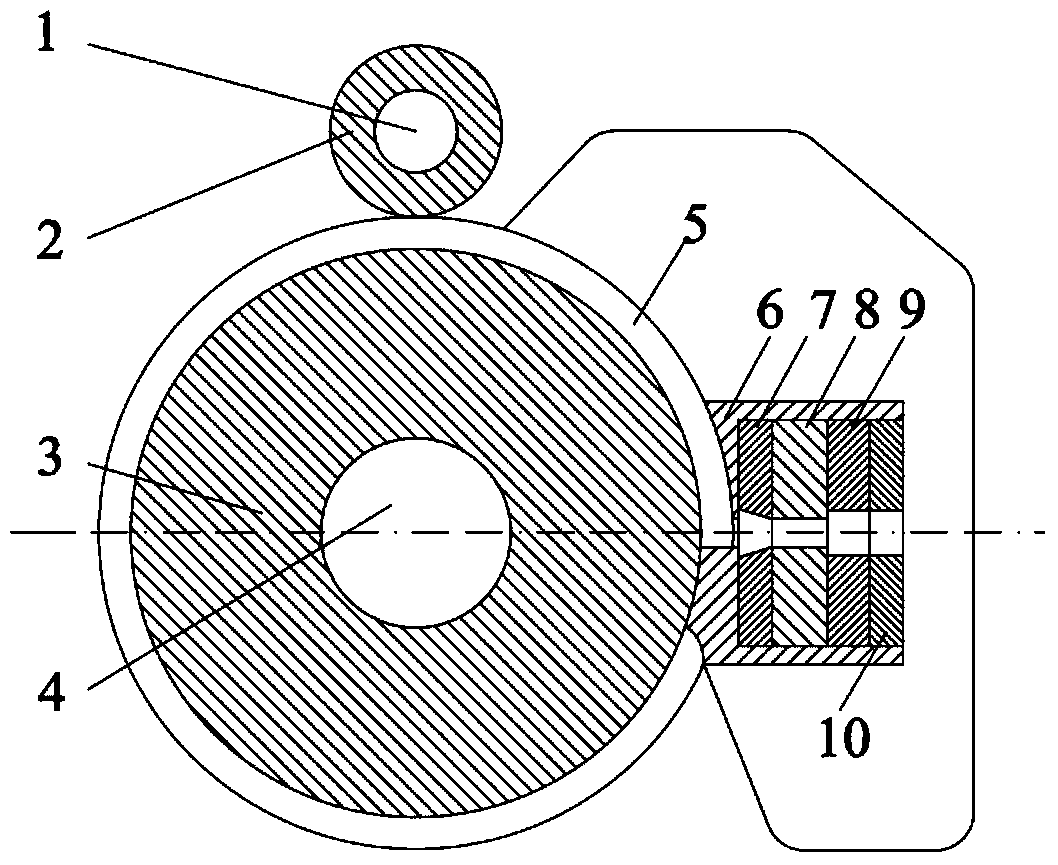

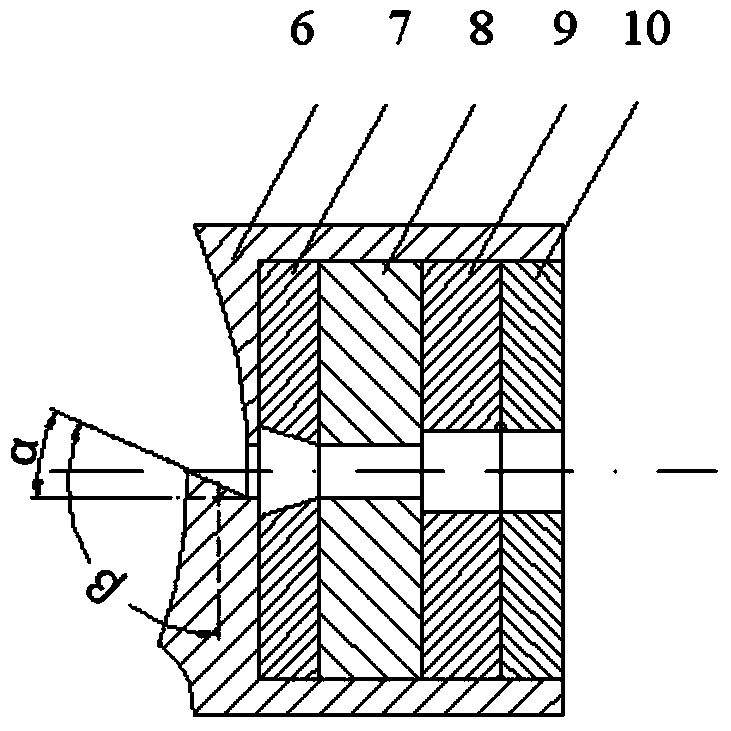

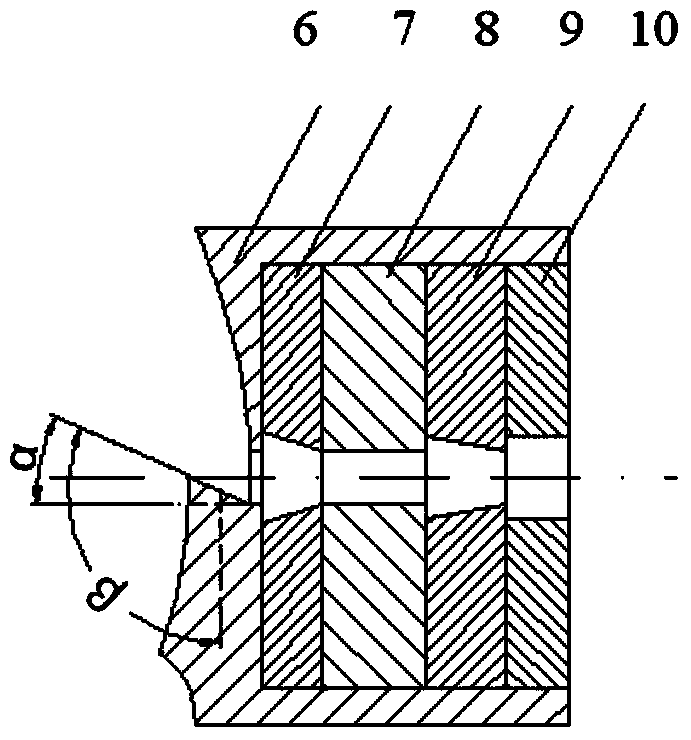

[0027] combine figure 2 , The composition of the first embodiment of the continuous equal radial angular extrusion combination die of the present invention includes a cavity 6 with a block, an inner die pad 7 , a die 8 , an outer die pad 9 and a fastening device 10 . Inside the cavity 6, an inner mold pad 7, a mold 8, an outer mold pad 9 and a fastening device 10 are sequentially placed. The material blocking block has a slope, and the angle α of the slope is 0°-45° as required. The mold 8 contains a sizing band hole, the length of which is 1 mm to 15 mm, and the sizing band is a circular or square column hole, and the aperture is equal to or slightly smaller than the feeding apert...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Taper | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com