Ball valve with valve ball having spiral silencing function

A valve ball and ball valve technology, applied in the valve's fluid energy absorption device, valve details, valve device and other directions, can solve the problems of complex structure, high manufacturing cost, large valve ball flow resistance, etc., to reduce impact damage and save energy. material, noise reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The ball valve of the present invention will be further described below with reference to the accompanying drawings.

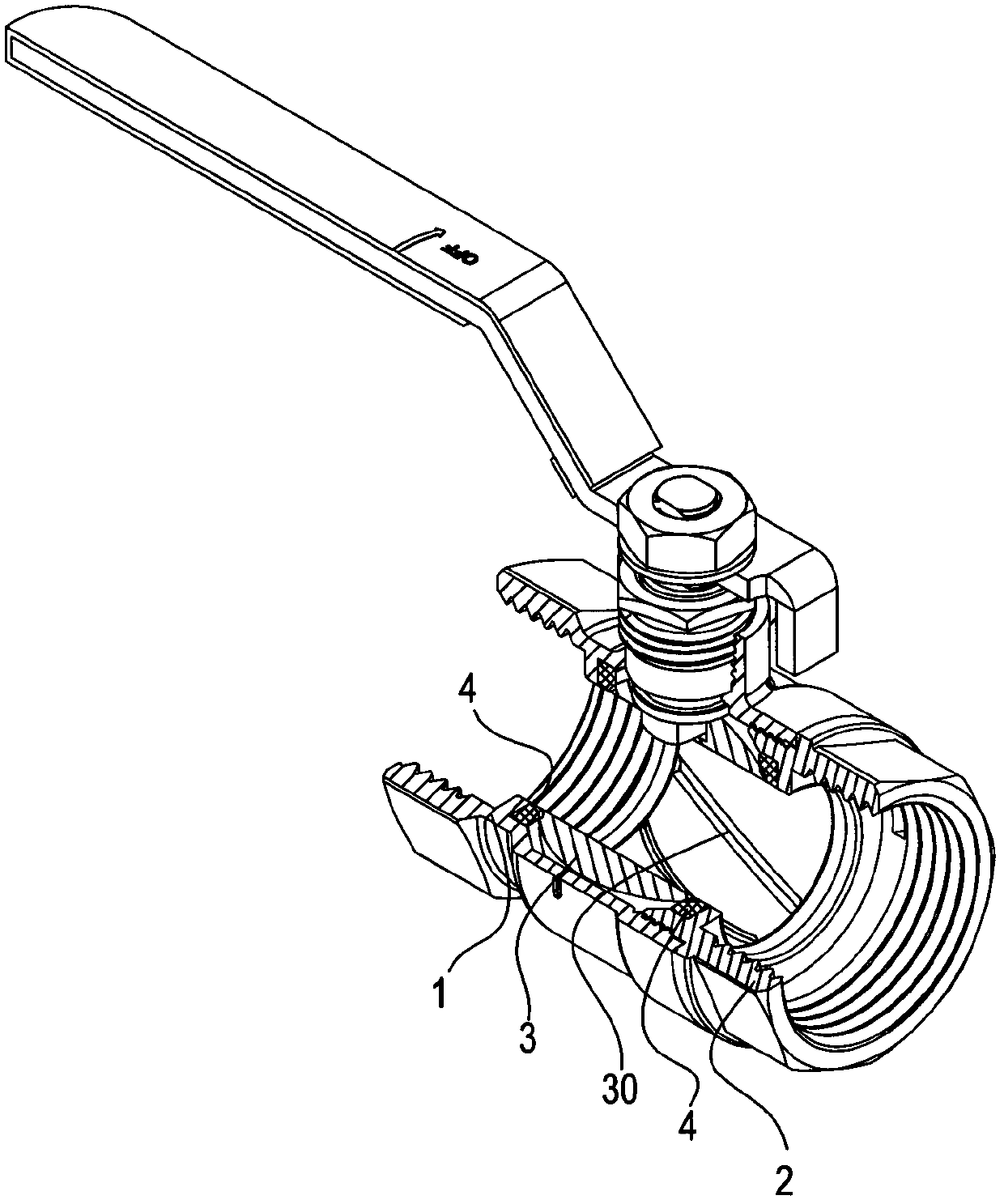

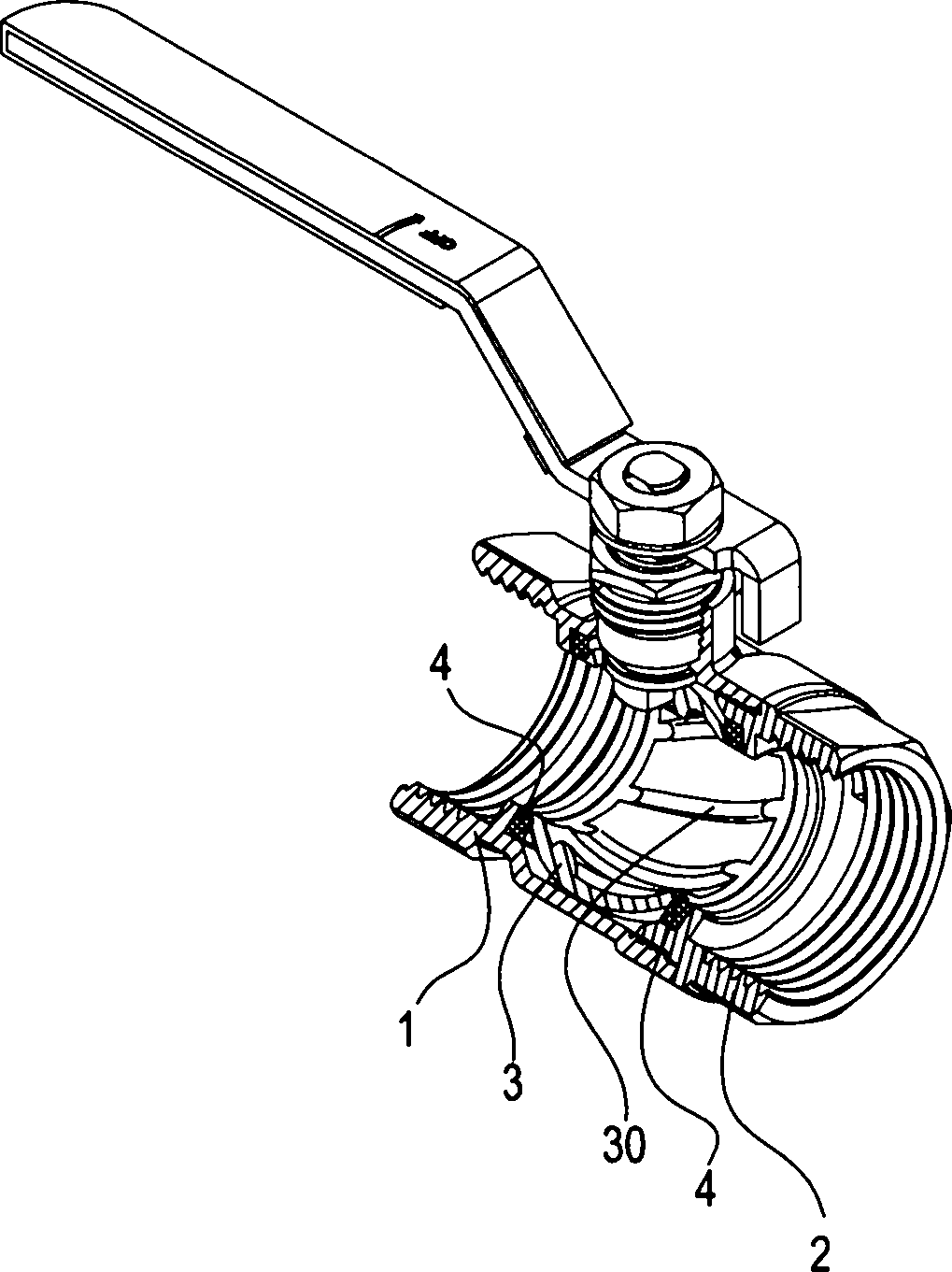

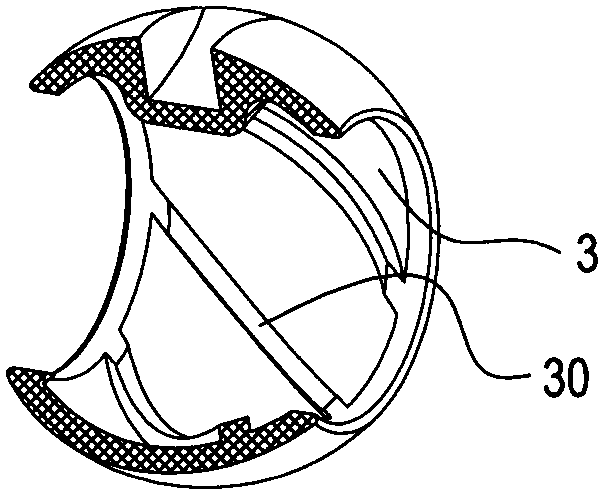

[0018] Such as figure 1 The ball valve shown is a ball valve with a spiral noise reduction function, which is used in the field of water supply and drainage in buildings. Fixed, a ball valve 3 is fixed between the ball valve body 1 and the ball valve cap 2, clamped by the sealing ring 4 on both sides, and three spiral guide ribs 30 are formed on the inner wall of the valve ball 3, and the cross section of the guide rib 30 It is a triangular protrusion, and the top of the triangular protrusion is arc-shaped. The diversion rib 30 is used to divert the flow of water in the pipeline, reduce the impact of the water flow, and reduce the noise. The angle between the diversion rib 30 and the center line of the valve ball is 8°; The included angle between the center line of the valve ball is 3° to 50°, and the number of diversion ribs 30 can be two, three, or ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com