Tape cassette and tape printer

A tape printer and tape cassette technology, applied in the directions of ink ribbon cassettes, printing, ink ribbons, etc., can solve the problems of increased printing tape volume, increased operating costs, and larger blank space of printing tapes, so as to suppress the generation of waste. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

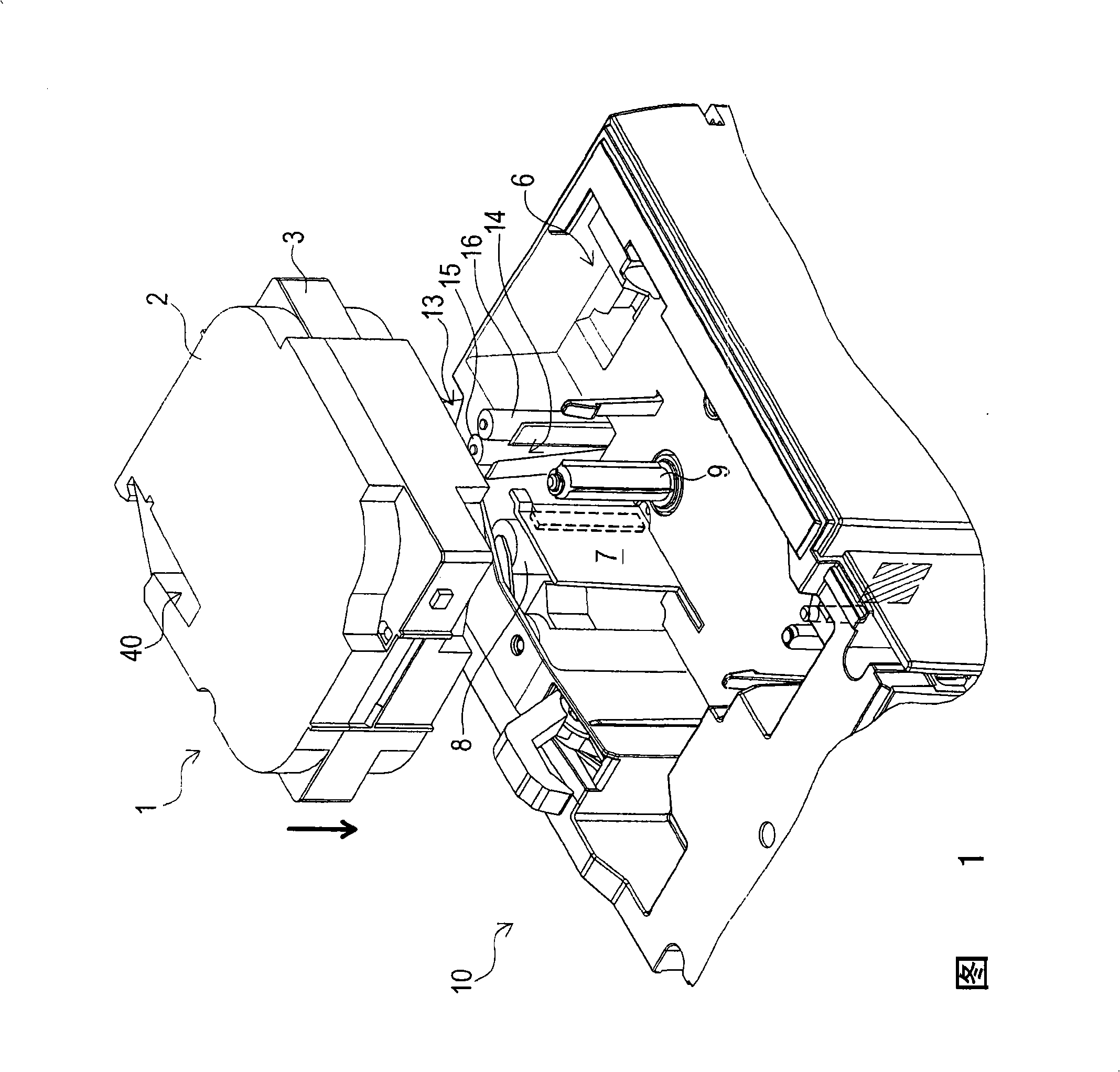

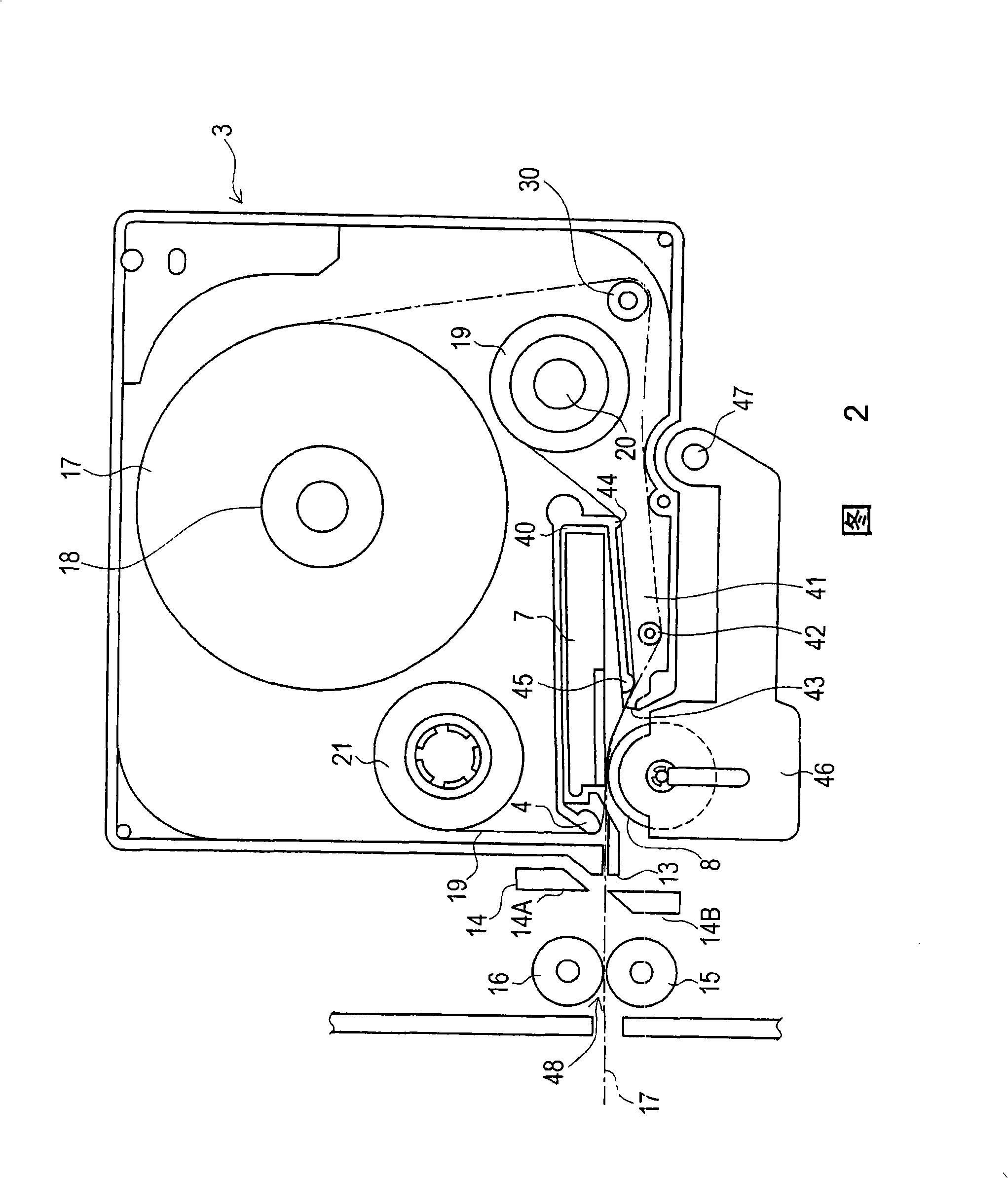

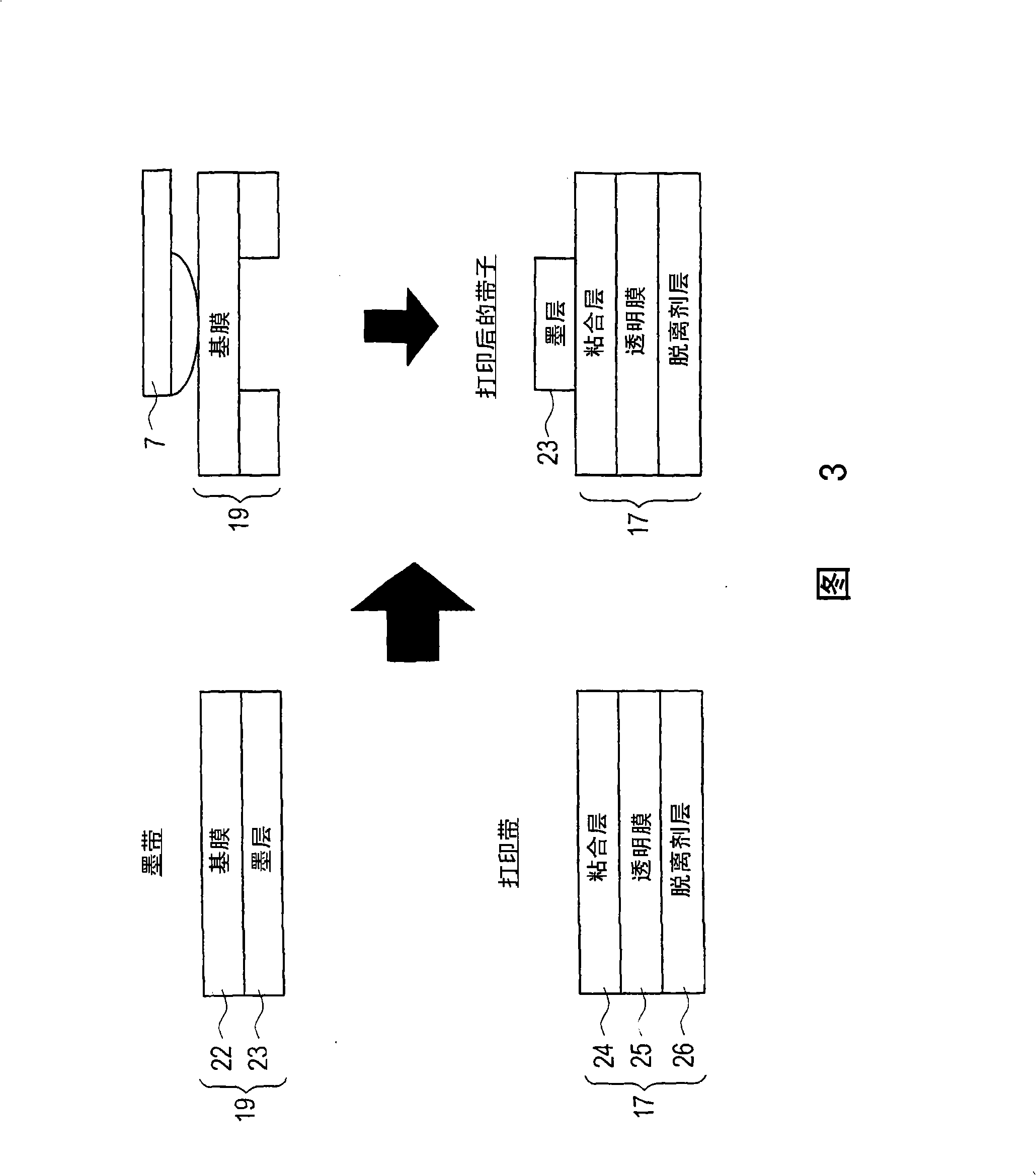

[0031] A description will now be given of a tape cassette and a tape printing apparatus according to a first embodiment based on FIGS. 1 and 2 .

[0032] In FIG. 1 , a tape cassette 1 is detachable in a cassette accommodating portion 6 provided in a tape printing apparatus 10 . The tape cassette 1 has an upper case 2 and a lower case 3 . The upper case 2 serves as a cover covering the upper surface of the lower case 3 . A film tape reel 18 is arranged at a position slightly higher than the central part of the lower casing 3, and a film tape 17 is wound on the reel 18, as shown in FIG. 2 . The lower housing 3 also has an ink ribbon reel 20 and an ink ribbon take-up reel 21 arranged at the lower right position of the film reel 18, the ink ribbon 19 is wound on the ink ribbon reel 20, and the ink ribbon take-up reel 21 takes the The tape reel 20 pulls out the ink ribbon 19 and winds up the ink ribbon 19 consumed when printing characters.

[0033] The tape cassette 1 has a ther...

no. 2 example

[0059] Next, a tape cassette and a tape printing apparatus according to a second embodiment will be described based on FIGS. 5 and 6 .

[0060] The tape cassette and tape printing apparatus according to the second embodiment have the same basic configuration as the tape cassette 1 and tape printing apparatus 10 according to the first embodiment. Therefore, in the following description, the same components as those of the tape cassette 1 and the tape printing apparatus 10 according to the first embodiment are denoted by the same reference numerals, and the description will focus on the same components as those of the tape cassette 1 and the tape printing apparatus 10 according to the first embodiment. On different components of the device 10.

[0061] In FIG. 5 , a tape cassette 1 having an upper case 2 and a lower case 3 is detachable in a tape cassette accommodating portion 6 provided in a tape printing apparatus 10 . The upper case 2 serves as a cover covering the upper sur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com