Robbon box with ribbon loose-proof mechanism

A color ribbon box and ribbon box technology, applied in the field of color ribbon box, can solve problems such as users forget to operate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] Hereinafter, an embodiment of the present invention will be described with reference to the accompanying drawings.

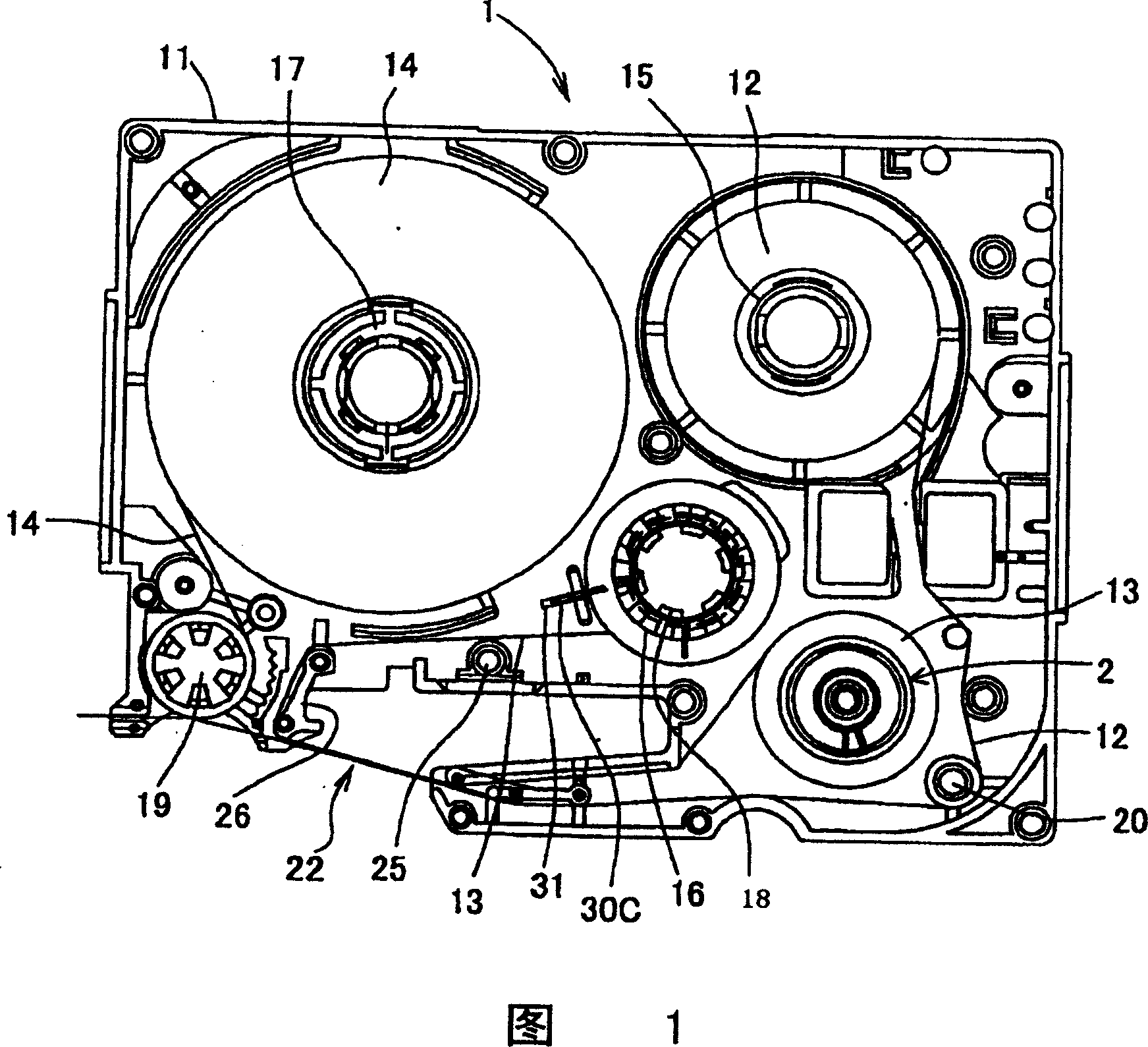

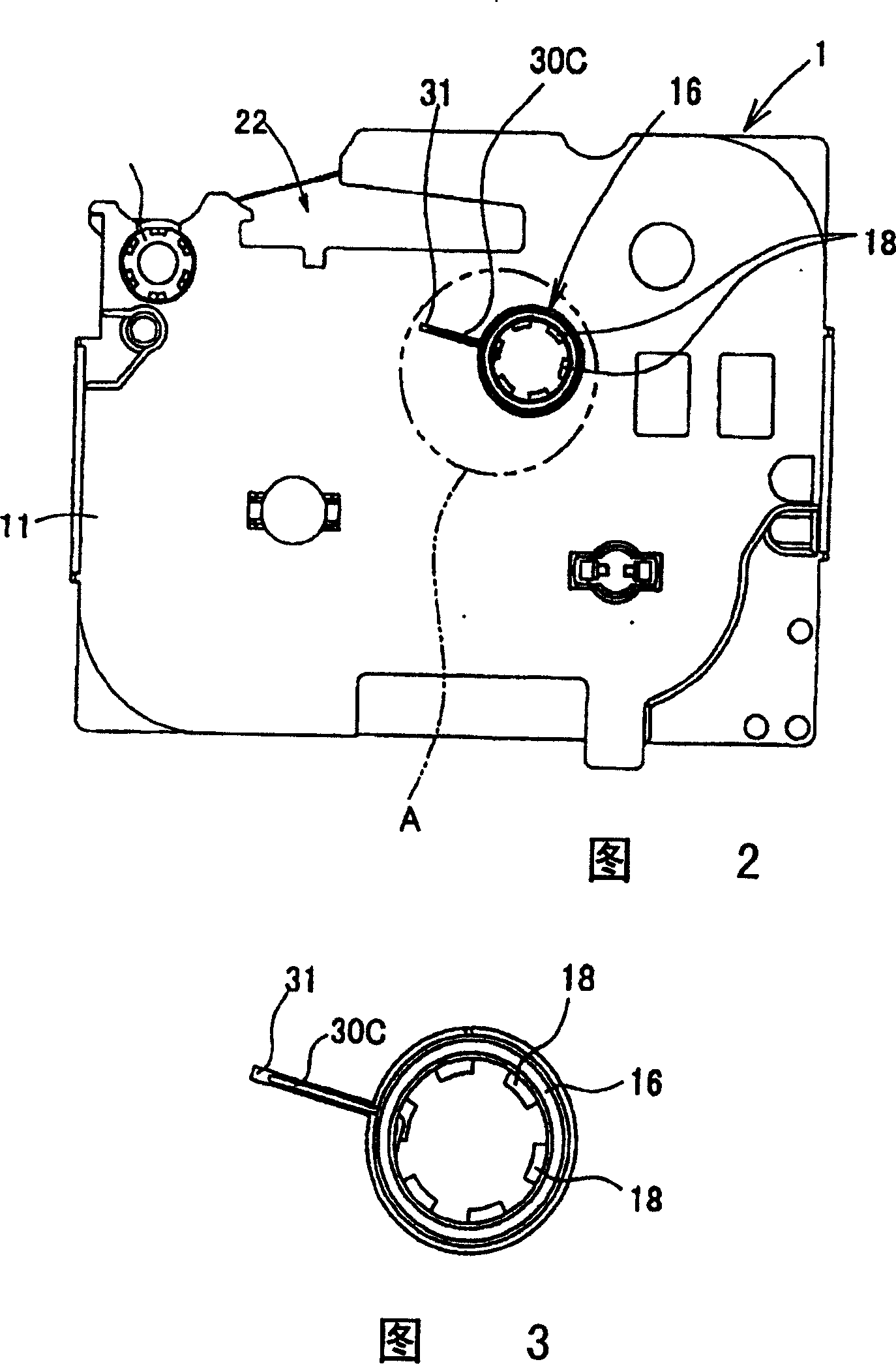

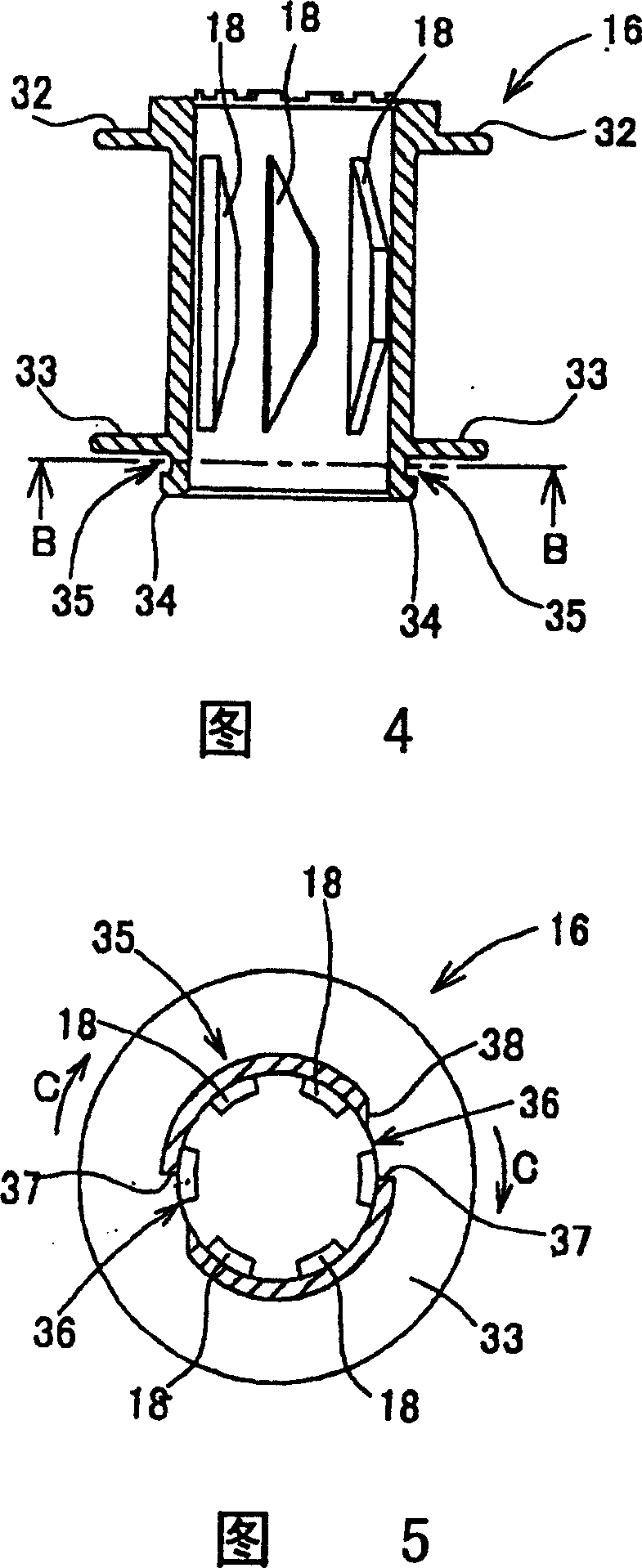

[0035] FIG. 1 shows an internal structure of a ribbon cassette of an ink ribbon cassette according to an embodiment of the present invention. The tape cassette 1 is used for a tape printer (not shown) that prints on a long-sized printing tape.

[0036] The tape cassette 1 includes a cassette body 11 made of resin, for example, which has a substantially rectangular parallelepiped form. The box body 11 is composed of an upper part and a lower part, only the lower part is shown in FIG. 1 . A transparent tape 12 as a printed medium, a ribbon 13 for printing on the transparent tape 12, and a colored double-sided adhesive tape 14 bonded to the back side of the printed transparent tape, they are wound on respective spools and housed in box 11. A take-up spool 16 for receiving used ribbon 13 is also disposed within the cassette body 11 .

[0037] The transpar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com