Thermal transfer sheet and protective layer transfer sheet

A thermal transfer sheet and thermal transfer layer technology, applied in printing, ink ribbon, copying/marking methods, etc., can solve problems such as insufficient heat resistance, insufficient plasticizer-resistant resin layer, instability, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

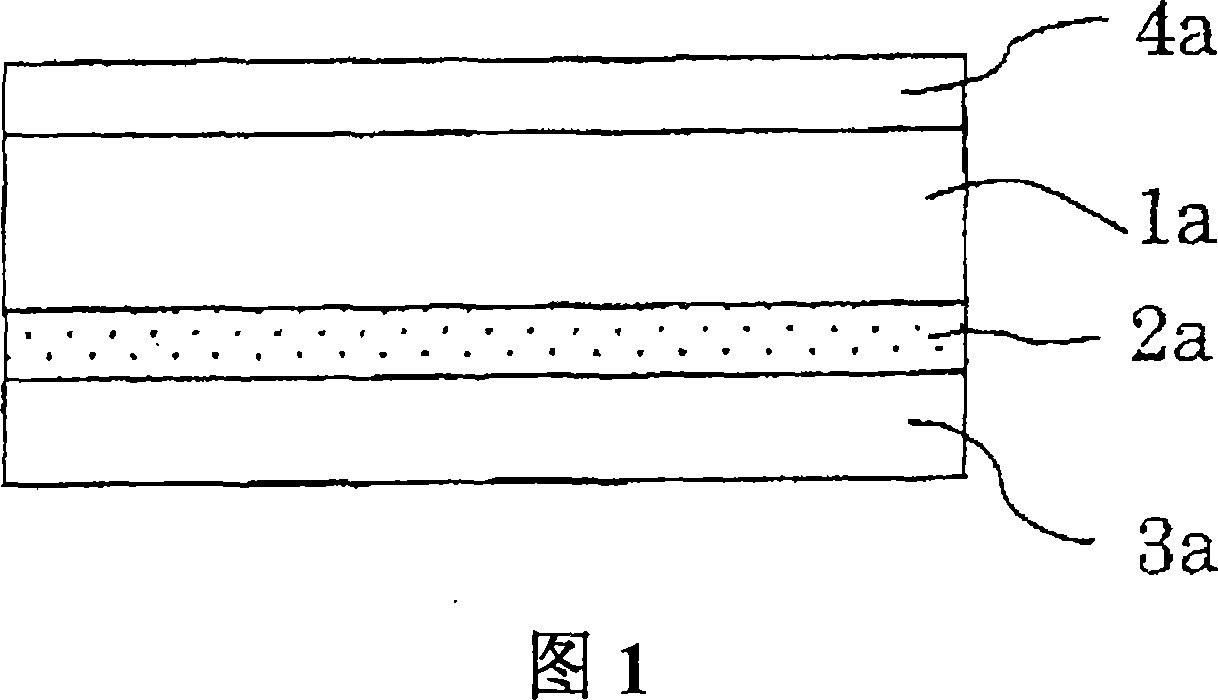

[0275] On a polyethylene terephthalate (PET) film having a thickness of 4.5 μm as a base material, the substrate layer coating solution 1 of the following composition is coated by the gravure coating method so that the dry coating amount is 0.06 g / m 2 , to form a substrate layer after drying.

[0276] Utilize the gravure coating method to coat the dye layer coating solution of the following composition on the top of this base layer, make the dry coating amount be 0.7g / m 2 , formed a dye layer after drying, and made the thermal transfer sheet of Example 1.

[0277] In addition, a heat-resistant slippery layer was previously formed on the surface of the other side of the base material by applying a heat-resistant slippery layer coating solution having the following composition by gravure coating so that the dry coating amount 1.0g / m 2 , forms a heat-resistant slippery layer after drying.

[0278]

[0279] Colloidal silicon oxide (Snow Tech OXS, particle size is 4nm~6nm, p...

Embodiment 2

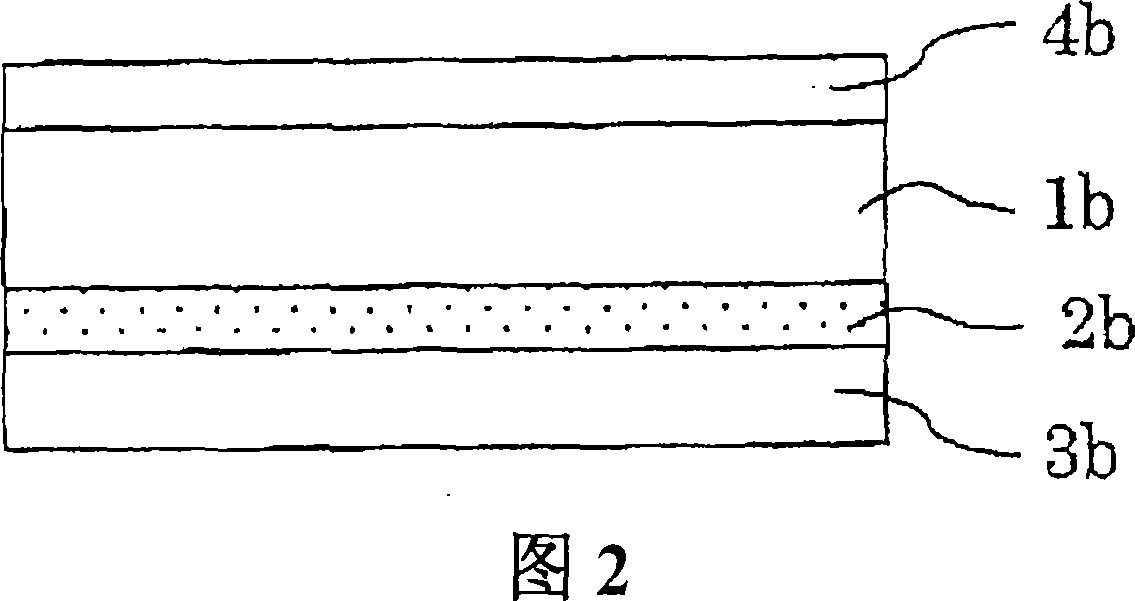

[0294] The thermal transfer sheet of Example 2 was produced in the same manner as in Example 1 except that the substrate layer in the thermal transfer sheet produced in Example 1 was changed to the following composition.

[0295]

[0296] Alumina sol (alumina sol 200, feathery shape, produced by Nissan Chemical Industry Co., Ltd.) 50 parts

[0297] 25 parts of water

[0298] 25 parts isopropanol

Embodiment 3

[0300] The thermal transfer sheet of Example 3 was produced in the same manner as in Example 1, except that the substrate layer in the thermal transfer sheet produced in Example 1 was changed to the following composition.

[0301]

[0302] Alumina sol (alumina sol 520, boehmite plate-like crystal form, produced by Nissan Chemical Industry Co., Ltd.) 25 parts

[0303] 37.5 parts of water

[0304] 37.5 parts of isopropanol

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com