Preparing method for polyamide hot melt adhesive

A technology of polyamide hot-melt adhesive and caprolactam, which is applied in the direction of adhesives, etc., can solve the problems that hot-melt adhesives cannot meet the requirements, and achieve the effects of narrow melting range, high melting point and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

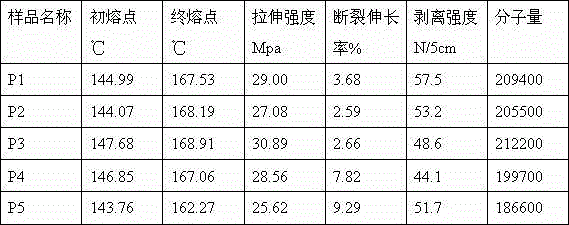

Examples

Embodiment 1

[0021] 237.3 g of caprolactam, 131.4 g of adipic acid, 109.04 g of hexamethylenediamine, 80.8 g of sebacic acid, 40.8 g of 1,5-pentamethylenediamine, 14.79 g of stearic acid, and 200 ml of water were added to a 2 L digitally controlled autoclave. Heat until the temperature in the kettle is 230~245℃, and start the polycondensation reaction. At this time, keep the pressure in the kettle at 1.6~1.8Mpa and react for 1.5h; Slowly reduced to normal pressure; in N 2 Reaction under normal pressure for 1.0 h under protection; after the reaction under normal pressure, pass nitrogen gas until the pressure in the kettle is 0.15~0.2Mpa, discharge while hot, and obtain the target product P1.

Embodiment 2

[0023] 226g of caprolactam, 160.6g of adipic acid, 132.24g of hexamethylenediamine, 40.4g of sebacic acid, 20.4g of 1,5-pentamethylenediamine, 7.38g of benzoic acid and 150ml of water were added to a 2L digitally controlled autoclave. Heat until the temperature in the kettle is 245~260℃, and start the polycondensation reaction. At this time, keep the pressure in the kettle at 1.5~1.6Mpa and react for 1.5h; Slowly reduced to normal pressure; in N 2 The reaction was carried out under normal pressure for 1.5 h under protection; after the normal pressure reaction was completed, nitrogen gas was passed until the pressure inside the kettle was 0.15-0.2 Mpa, and the material was discharged while it was hot to obtain the target product P2.

Embodiment 3

[0025] 237.3 g of caprolactam, 146 g of adipic acid, 110.2 g of hexamethylenediamine, 60.6 g of sebacic acid, 40.8 g of 1,5-pentamethylenediamine, 4.21 g of acetic acid, and 150 ml of water were added to a 2L digitally controlled autoclave. Heat until the temperature in the kettle is 245~260℃, and start the polycondensation reaction. At this time, keep the pressure in the kettle at 1.5~1.7Mpa and react for 1.2h; Slowly reduced to normal pressure; in N 2 The reaction was carried out under normal pressure for 1.5 hours under protection; after the reaction under normal pressure, nitrogen gas was passed until the pressure in the kettle was 0.15~0.2Mpa, and the material was discharged while it was hot to obtain the target product P3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com