Polyimide composition and preparation method thereof

A technology of polyimide and composition, which is applied in the field of additively manufactured polyimide composition and its preparation, and can solve problems such as difficulty in forming dense sintered parts, low mechanical properties of sintered parts, and difficult processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

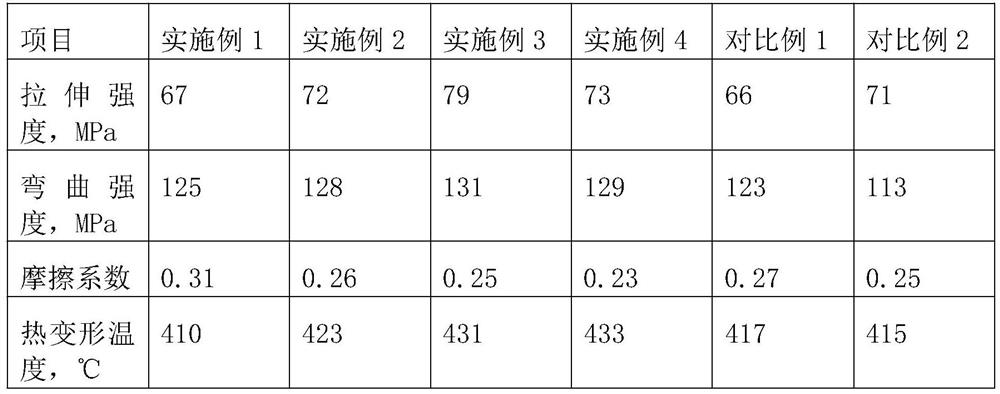

Examples

Embodiment 1

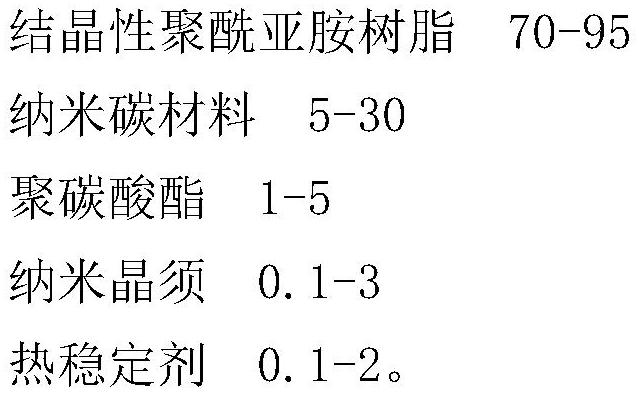

[0029] (1) 92 parts of crystallinity polyimide and 1 part of polycarbonate resin were pulverized together using an ultrafine pulverizer, and sieved in a mechanical vibrating sieve to obtain a mixed powder.

[0030] (2) adding the mixed powder prepared in step (1), 5 parts of nano-carbon materials, 1 part of nano-whiskers, and 1 part of thermal stabilizer into a high-speed mixer and mixed uniformly to obtain a polyimide for selective sintering powder material.

Embodiment 2

[0032] (1) 84 parts of crystallinity polyimide and 3 parts of polycarbonate resin were pulverized together using an ultrafine pulverizer, and sieved in a mechanical vibrating sieve to obtain a mixed powder.

[0033] (2) adding the mixed powder prepared in step (1), 10 parts of nano-carbon materials, 2 parts of nano-whiskers, and 1 part of thermal stabilizer into a high-speed mixer and mixing uniformly to obtain a polyimide for selective sintering powder material.

Embodiment 3

[0035] (1) Pulverize the crystalline polyimide and polycarbonate resin with an ultra-fine pulverizer respectively, sieve to obtain components of 20-100 microns, and weigh 75 parts of crystalline polyimide and 5 parts of polycarbonate , to obtain mixed powder;

[0036] (2) pulverize the nano-carbon material, nano-whisker and thermal stabilizer respectively, sieve to obtain components of 20-100 microns, mix the mixed powder prepared in step (1), 15 parts of nano-carbon material, 3 parts of nano- The whiskers and 2 parts of heat stabilizer are added into a high-speed mixer and mixed uniformly to obtain a polyimide powder material for selective sintering.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com