5-aminolevulinic acid hydrochloride crystal form and preparation method thereof

A technology of aminolevulinic acid hydrochloride crystal and aminolevulinic acid hydrochloride, applied in the field of 5-aminolevulinic acid hydrochloride crystal form and its preparation, can solve the problem of not paying attention to product crystal form and product quality Instability, neglect of important influences and other issues, to achieve the effect of favorable storage and transportation, mild conditions, uniform particle size and luster

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

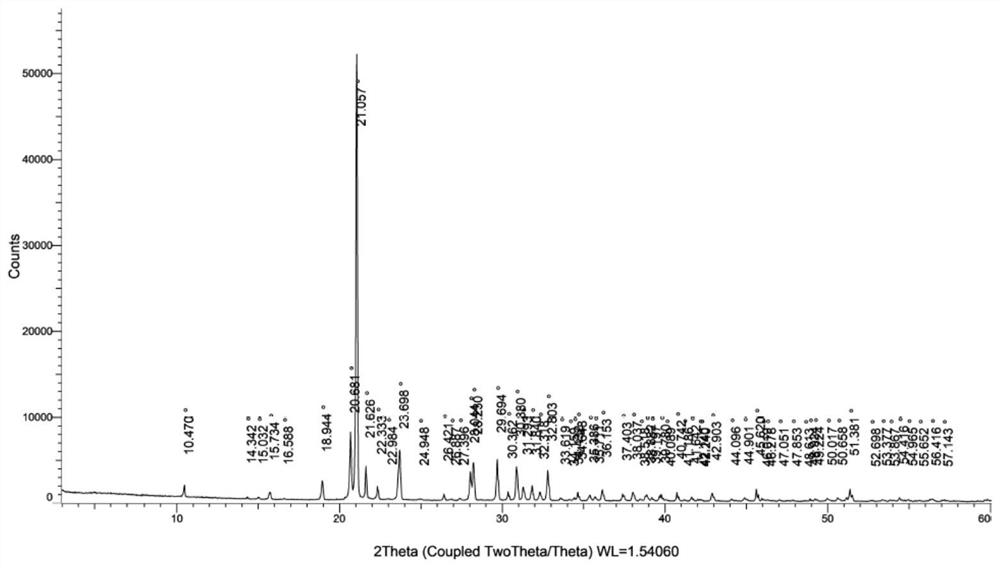

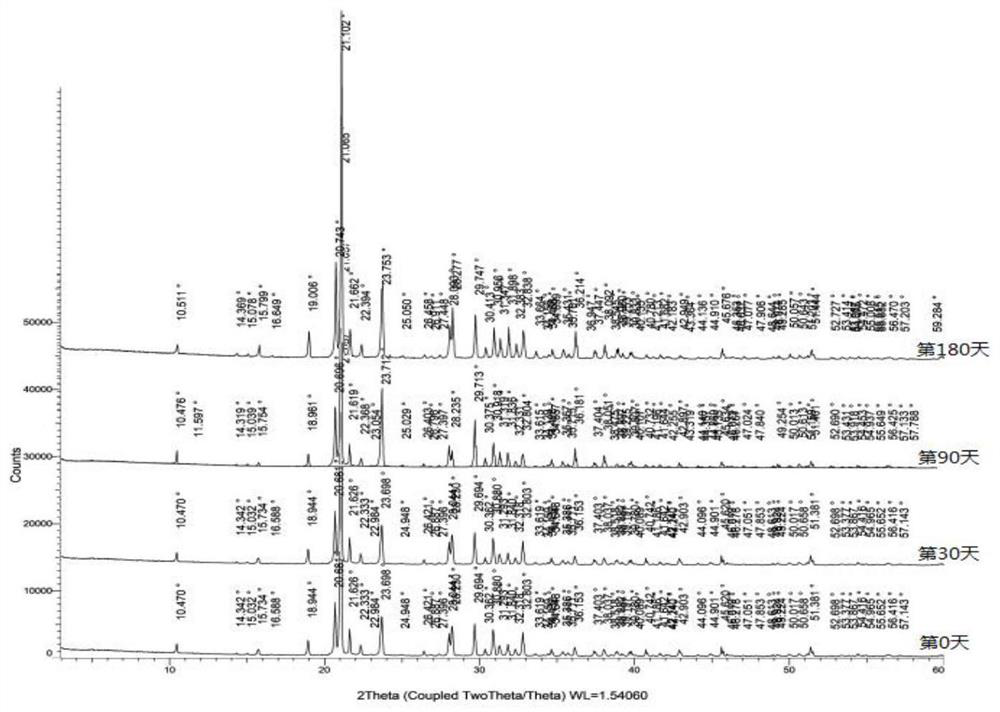

[0027] Dissolve 10 grams of crude 5-aminolevulinic acid hydrochloride in 20 grams of pure water at room temperature, filter to remove mechanical impurities, slowly add 200 ml of methanol dropwise to the solution, wait until turbidity appears, suspend the dropwise addition, and continue stirring for 30 Minutes to grow the crystal, and then continue to drop the remaining methanol. After the dropwise addition is completed, filter, wash the filter cake with an appropriate amount of methanol, put the solid into a vacuum drying oven, the vacuum degree is -0.095--0.098Mpa, the temperature is 20-40°C, and the drying time is 6-8 hours to obtain the 5 -Aminolevulinic acid hydrochloride crystal form β, the X-RD powder diffraction pattern of the product has characteristic peaks at 2θ=21.0±0.5°, 23.7±0.5°, 29.7±0.5°, 30.9±0.5°, 36.2±0.5° , Solubility (25°C in water) can reach 0.60g / ml, excellent solubility.

Embodiment 2

[0029] Dissolve 10 grams of crude 5-aminolevulinic acid hydrochloride in 10 grams of pure water at room temperature, filter to remove mechanical impurities, slowly add 200 ml of ethanol dropwise to the solution, wait until turbidity appears, suspend the dropwise addition, and continue stirring for 30 Minutes to grow the crystal, and then continue to drop the remaining ethanol. After the dropwise addition is completed, filter, wash the filter cake with an appropriate amount of ethanol, put the solid into a vacuum drying oven, the vacuum degree is -0.095--0.098Mpa, the temperature is 20-40°C, and the drying time is 6-8 hours to obtain the 5 -Aminolevulinic acid hydrochloride crystal form β, the X-RD powder diffraction pattern of the product has characteristic peaks at 2θ=21.0±0.5°, 23.7±0.5°, 29.7±0.5°, 30.9±0.5°, 36.2±0.5° , Solubility (25°C in water) can reach 0.62g / ml, excellent solubility.

Embodiment 3

[0031] Dissolve 10 grams of crude 5-aminolevulinic acid hydrochloride in 10 grams of pure water at room temperature, filter to remove mechanical impurities, mix 100ml of ethanol and 100ml of isopropanol, and slowly add it dropwise to the solution until it becomes turbid , suspend the dropwise addition, continue to stir for 30 minutes to grow the crystal, and then continue to dropwise add the remaining mixed alcohol solution. After the dropwise addition is completed, filter, wash the filter cake with an appropriate amount of mixed alcohol, put the solid into a vacuum drying oven, the vacuum degree is -0.095--0.098Mpa, the temperature is 20-40°C, and the drying time is 6-8 hours to obtain the described 5-Aminolevulinic acid hydrochloride crystal form β, the X-RD powder diffraction pattern of the product has a characteristic peak at [A1], the solubility (25°C in water) can reach 0.61g / ml, and the solubility is excellent.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| solubility (mass) | aaaaa | aaaaa |

| solubility (mass) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com