Solid inks containing ketone waxes and branched amides

A technology of solid ink and branched chain amide, which is applied in the direction of ink, copying/marking method, printing, etc., can solve the problem of expensive polyethylene wax, and achieve the effect of high polarity, narrow molecular weight distribution, and low manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

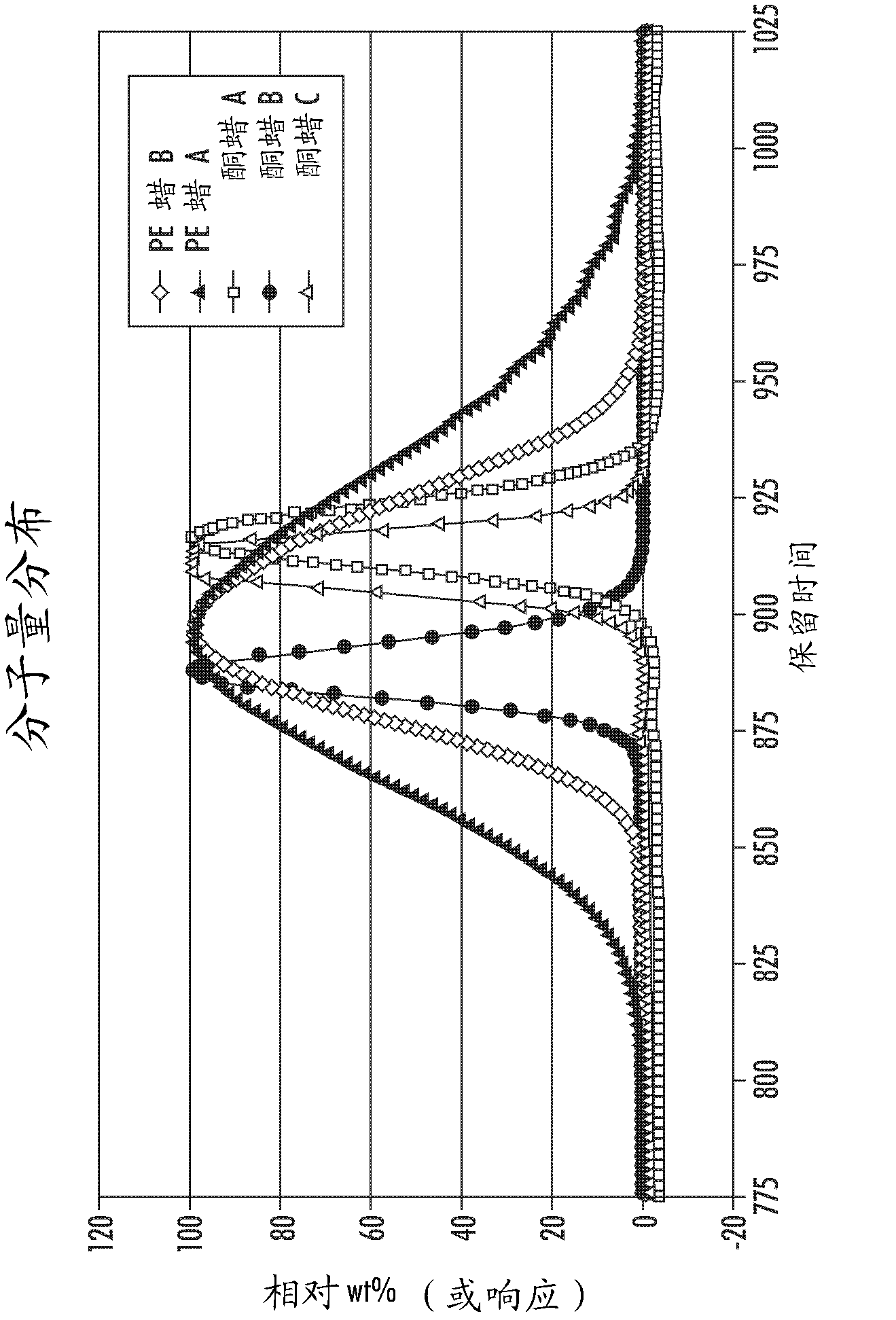

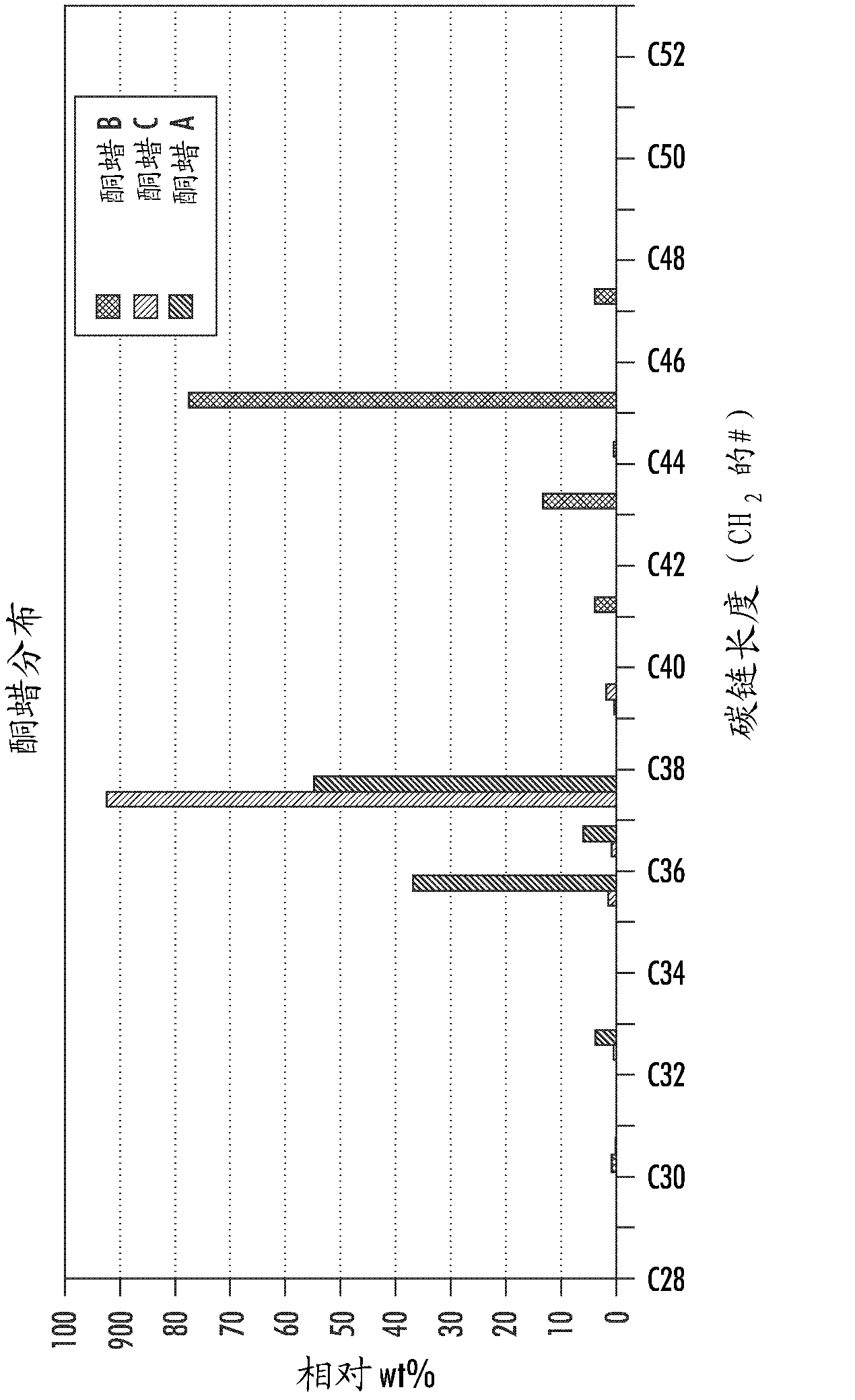

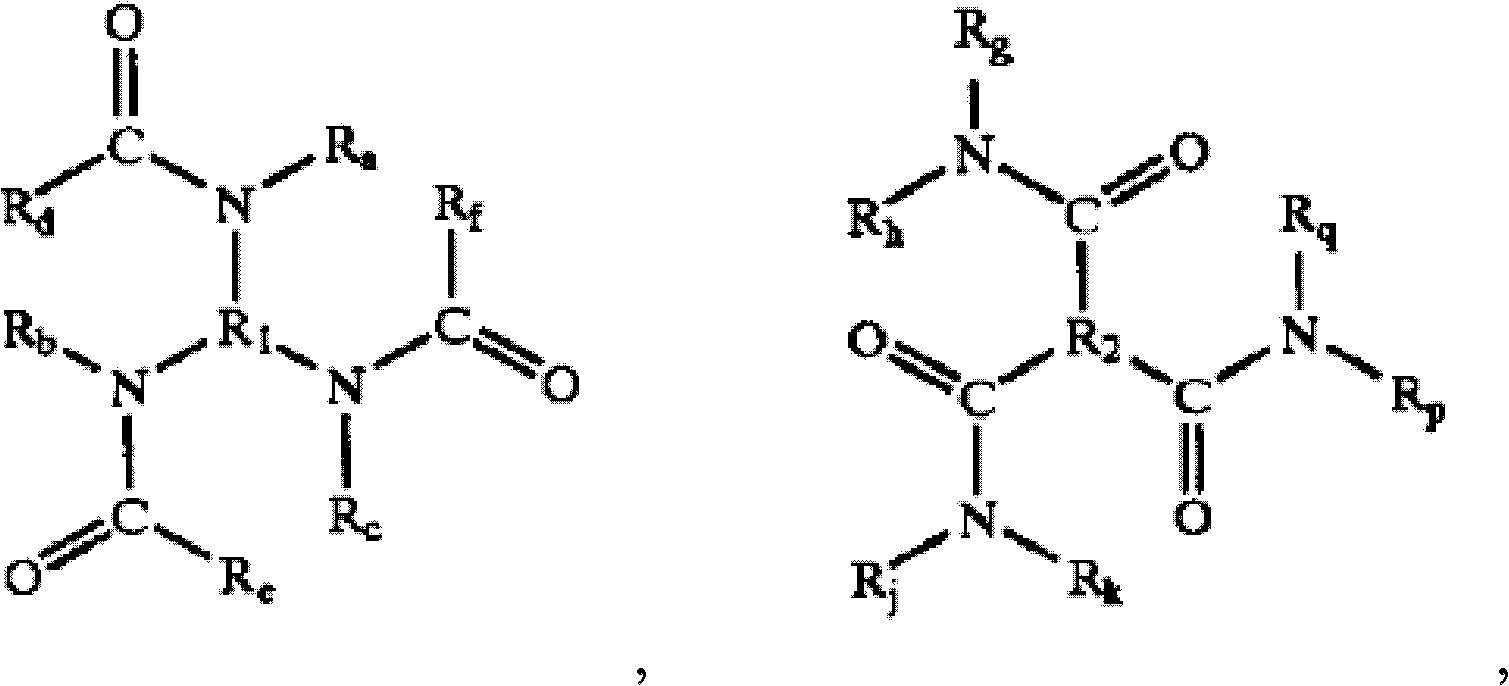

[0157] Example 1 and Comparative Examples 1 and 2. Oil Ink compositions were prepared using the formulations shown in Table 1 below. First, an ink base was prepared by mixing at 110°C by melting and uniformly blending the following components using an overhead stirrer: each individual wax (PE wax A, PE wax B, or ketone wax A); triamide Wax (as described in U.S. Patent No. 6,860,930); Kenamide S-180 (a stearyl stearamide), commercially available from Chemtura Corp.; KE-100 resin (a form of hydroabietic acid (abietic acid) Triglycerides), commercially available from Arakawa Chemical Industries, Ltd.; R12, a polyurethane resin (adduct of three equivalents of stearyl isocyanate and a glycerol-based alcohol, as implemented in U.S. Patent 6,309,453 Prepared as described in Example 4, the entire disclosure of which is incorporated herein by reference); NAUGARD-445 (an antioxidant) obtained from Crompton Corp.; black dye (Savinyl Black NS, available from Clariant); and Disperse Or...

Embodiment 2-5 and

[0168] Examples 2-5 and Comparative Examples 3-4. Ink compositions were prepared in the same manner as in Example 1 and Comparative Examples 1 and 2 above, except that the formulations shown in Table 2 below were used. These ink formulations are cyan in color.

[0169] Formulation and properties of table 2 cyan ink

[0170]

[0171]

[0172] The ink is commercially available in Xerox 8400 printer but at a jetting temperature of about 110°C. Its print quality and image quality results are summarized in Table 3. Comparative Example 5 is a commercially available Xerox 8860 printer's cyan ink, while Comparative Example 6 is a commercially available Xerox Cyan ink for the 8400 printer.

[0173] Table 3 Print Quality and Image Quality Results

[0174]

[0175] For print quality and image quality performance, the inks of Examples 4 and 5 (made from ketone wax) showed better performance with higher smearing compared to Comparative Example 3 (made from polyethylene ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com