Medium temperature aluminum alloy brazing solder and preparing method thereof

A technology for aluminum alloys and master alloys, applied in welding equipment, metal processing equipment, welding/cutting media/materials, etc., can solve problems such as high welding temperature and low percentage of magnesium, achieve low welding temperature, improve Good wettability and wetting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

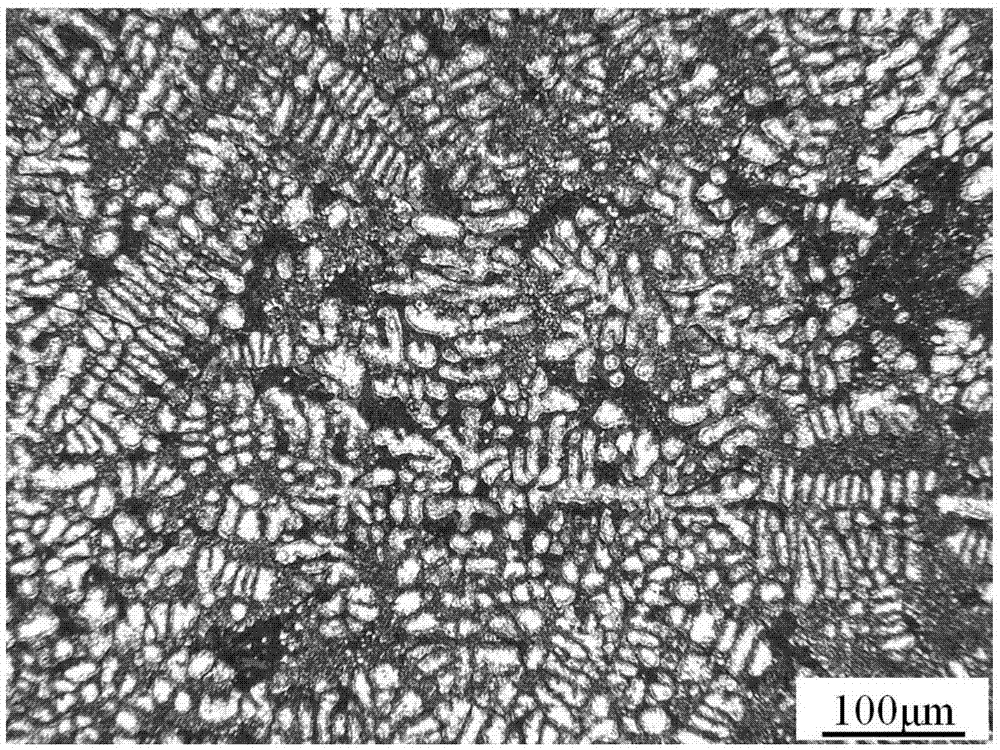

Embodiment 1

[0028] Formula: Mg1.5g, Cu12g and Al-12Si master alloy 86.5g.

[0029] Preparation method: take raw materials, smelt, the smelting temperature is 700-800°C, preheat the mold to 390-410°C, pour, pour, and get ready.

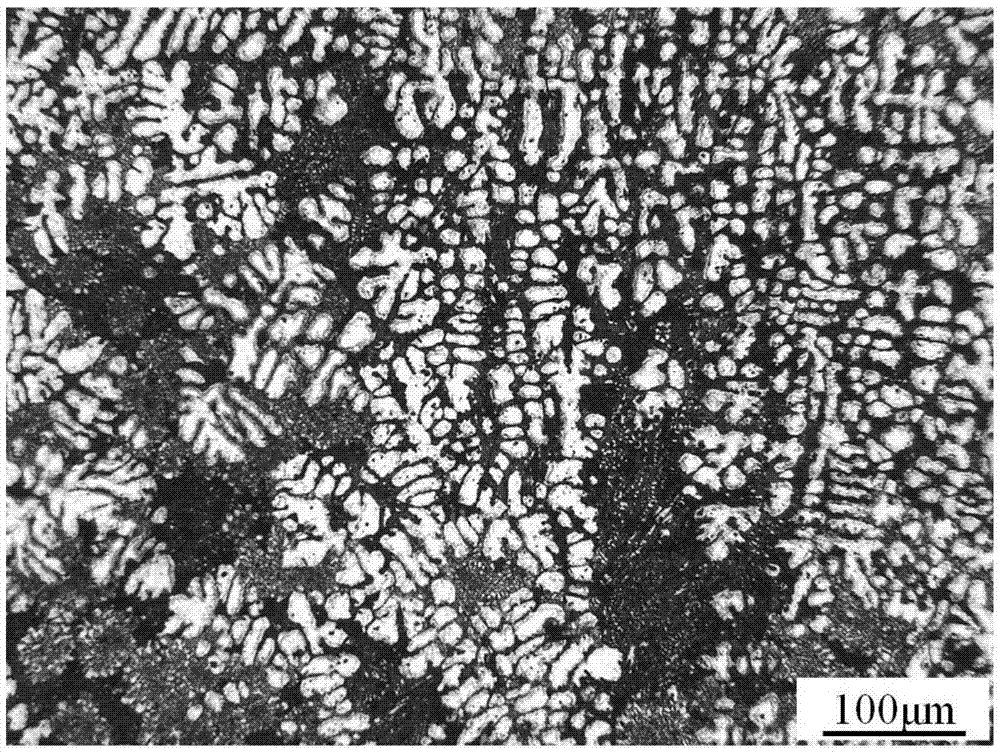

Embodiment 2

[0031] Recipe: Mg3g, Cu25g and Al-12Si master alloy 95g.

[0032] Preparation method: take raw materials, smelt, the smelting temperature is 700-800°C, preheat the mold to 390-410°C, pour, pour, and get ready.

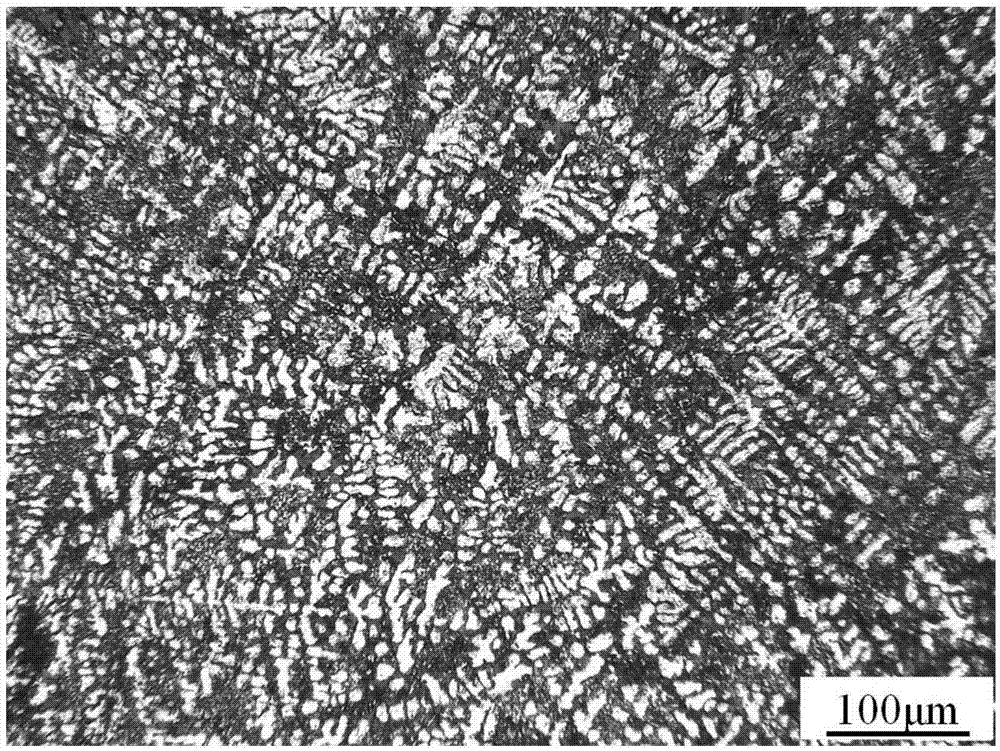

Embodiment 3

[0034] Formula: Mg2g, Cu18g, Al-12Si master alloy 93g.

[0035] Preparation method: take raw materials, smelt, the smelting temperature is 700-800°C, preheat the mold to 390-410°C, pour, pour, and get ready.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com