Preparation method of vinyl distearamide

A technology of vinyl bisstearamide and stearic acid, which is applied in the chemical industry, can solve the problems of lowering the reaction temperature, easy yellowing of the color, complicated process, etc., and achieves the effect of reducing side reactions, reducing chroma, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

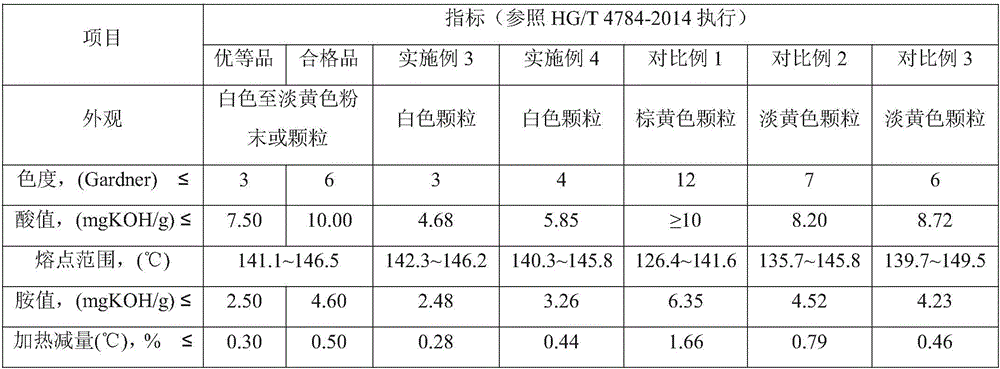

Examples

Embodiment 1

[0019] Embodiment 1 prepares p-toluenesulfonic acid / SAPO-34 supported solid acid catalyst

[0020] Dissolve p-toluenesulfonic acid in deionized water, prepare a p-toluenesulfonic acid solution with a mass fraction of 30% as an impregnation solution, use SAPO-34 molecular sieve after roasting at 500°C for 3.5h as a carrier, and adjust the liquid-solid ratio 2.0mL / g is placed in p-toluenesulfonic acid solution, impregnated by ultrasonic impregnation, and the impregnation time is 12h; the above impregnated material is dried at 120°C for 12h, and roasted in an air atmosphere at 550°C in a muffle furnace for 4h , to obtain p-toluenesulfonic acid / SAPO-34 supported solid acid catalyst.

Embodiment 2

[0021] Embodiment 2 prepares phosphoric acid / SiO2-Al2O3 supported solid acid catalyst

[0022] S1: Take aluminum nitrate and dissolve it in absolute ethanol at a solid-to-liquid ratio of 0.10 g / mL to prepare an ethanol solution of aluminum nitrate, add 40% of its volume to tetraethyl orthosilicate and 15% of its volume to 30% of its volume fraction Aqueous urea solution, stirred for 10 minutes, stirred and refluxed at 80°C to form a gel, dried at 120°C for 8 hours, and calcined in a muffle furnace at 550°C for 3 hours to obtain SiO 2 -Al 2 o 3 composite oxides;

[0023] S2: SiO prepared from S1 with 55% phosphoric acid solution as the impregnating solution 2 -Al 2 o 3 The composite oxide is used as a carrier and placed in a phosphoric acid solution at a liquid-solid ratio of 1.0mL / g, and is impregnated by ultrasonic impregnation for 16 hours; the impregnated material is dried at 120°C for 12 hours, and placed in a muffle furnace in an air atmosphere Calcined at 550°C for...

Embodiment 3

[0024] Embodiment 3 prepares vinyl bis stearamide

[0025] Add stearic acid and a composite antioxidant of 0.28% stearic acid mass into the reactor, and feed N while stirring. 2 After 10 minutes, slowly raise the temperature to 100°C to melt all the stearic acid, add ethylenediamine and a composite catalyst of 0.20% by mass of stearic acid, react at a constant temperature for 2 hours, then slowly raise the temperature to 180°C, and react at a constant temperature for 4 hours to make it The dehydration reaction is carried out, and the water generated during the reaction is composed of N 2 Take out, stop the reaction, cool to 160°C and discharge. Among them, the molar ratio of stearic acid and ethylenediamine is 1:0.58; the mass ratio of antioxidant 1076, antioxidant DLTDP and antioxidant T501 in the composite antioxidant is 0.20:0.36:1; The p-toluenesulfonic acid / SAPO-34 supported solid acid catalyst and phosphoric acid / SiO that example 1 and embodiment 2 make 2 -Al 2 o 3 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com