Method for preparing spinnable asphalt through co-heating condensation polymerization of anhydride-modified coal asphalt and kerosene co-refining residues

A kerosene co-refining residue and acid anhydride modification technology are applied in the processing of tar pitch/petroleum pitch/natural pitch, chemically processing tar pitch/petroleum pitch/natural pitch, melt spinning, etc. Control, low softening point increase, poor spinning performance, etc., to achieve the effect of good spinnability, good fluidity and high softening point

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

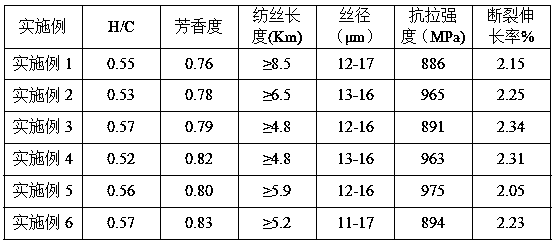

Examples

Embodiment 1

[0026] Medium-low temperature coal tar pitch (softening point: 90°C, ash content 0.2wt%) was crushed to ≤20 mesh, mixed with tetrahydrofuran at a mass ratio of 1:4, the soluble components of medium-temperature coal tar pitch were extracted and filtered, and vacuum-dried for 12 hours to obtain The ash content was 0.03% by weight of asphaltenes B.

[0027] Crush the kerosene co-refining residue (ash content 29wt%) to ≤20 mesh, mix it with tetrahydrofuran at a mass ratio of 1:4, extract and filter the soluble components of the kerosene co-refining residue, and vacuum dry for 12 hours to obtain an ash content of 0.02wt% of asphaltene A.

[0028] Mix the obtained asphaltenes B with pyromellitic anhydride and maleic anhydride in a ratio of 20:1:1 (weight ratio), put it into the reactor, and continuously feed nitrogen gas at a rate of 20mL / min·g, Heat to 350°C at a heating rate of 9°C / min and stay for 3 hours. The obtained asphalt has a softening point of 175°C and a softening melt...

Embodiment 2

[0031] Grind medium-low temperature coal tar pitch (softening point: 88°C, ash content 0.2wt%) to ≤20 mesh, mix with tetrahydrofuran at a mass ratio of 1:5, extract and filter out the soluble components of medium-temperature coal tar pitch, and vacuum dry for 12 hours to obtain The ash content was 0.03% by weight of asphaltenes B.

[0032] Crush the kerosene co-refining residue (ash content 27wt%) to ≤20 mesh, mix with tetrahydrofuran at a mass ratio of 1:5, extract and filter out the soluble components of kerosene co-refining residue, and vacuum dry for 12 hours to obtain an ash content of 0.01wt% of asphaltene A.

[0033] Mix the obtained asphaltenes B with pyromellitic anhydride and maleic anhydride in a ratio of 15:2:1 (weight ratio), put it into the reactor, and continuously feed nitrogen gas at a rate of 30mL / min·g, Heat to 370°C at a heating rate of 10°C / min and stay for 1 hour. The obtained asphalt has a softening point of 179°C and a softening melting range of 179-1...

Embodiment 3

[0036] Medium-low temperature coal tar pitch (softening point: 89°C, ash content 0.2wt%) was crushed to ≤20 mesh, mixed with tetrahydrofuran at a mass ratio of 1:7, the soluble components of medium-temperature coal tar pitch were extracted and filtered, and dried in vacuum for 12 hours to obtain The ash content was 0.02% by weight of asphaltenes B.

[0037] Crush the kerosene co-refining residue (ash content 28wt%) to ≤20 mesh, mix it with tetrahydrofuran at a mass ratio of 1:7, extract and filter the soluble components of the kerosene co-refining residue, and vacuum dry for 12 hours to obtain an ash content of 0.01wt% of asphaltene A.

[0038] Mix the obtained asphaltene B with pyromellitic anhydride and maleic anhydride at a ratio of 15:1:2 (weight ratio), put it into the reactor, and continuously feed nitrogen at a rate of 10mL / min·g, Heat to 420°C at a heating rate of 1°C / min and stay for 5 hours. The obtained asphalt has a softening point of 180°C and a softening meltin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com