Selective laser sintering polyimide powder material and preparation and application methods thereof

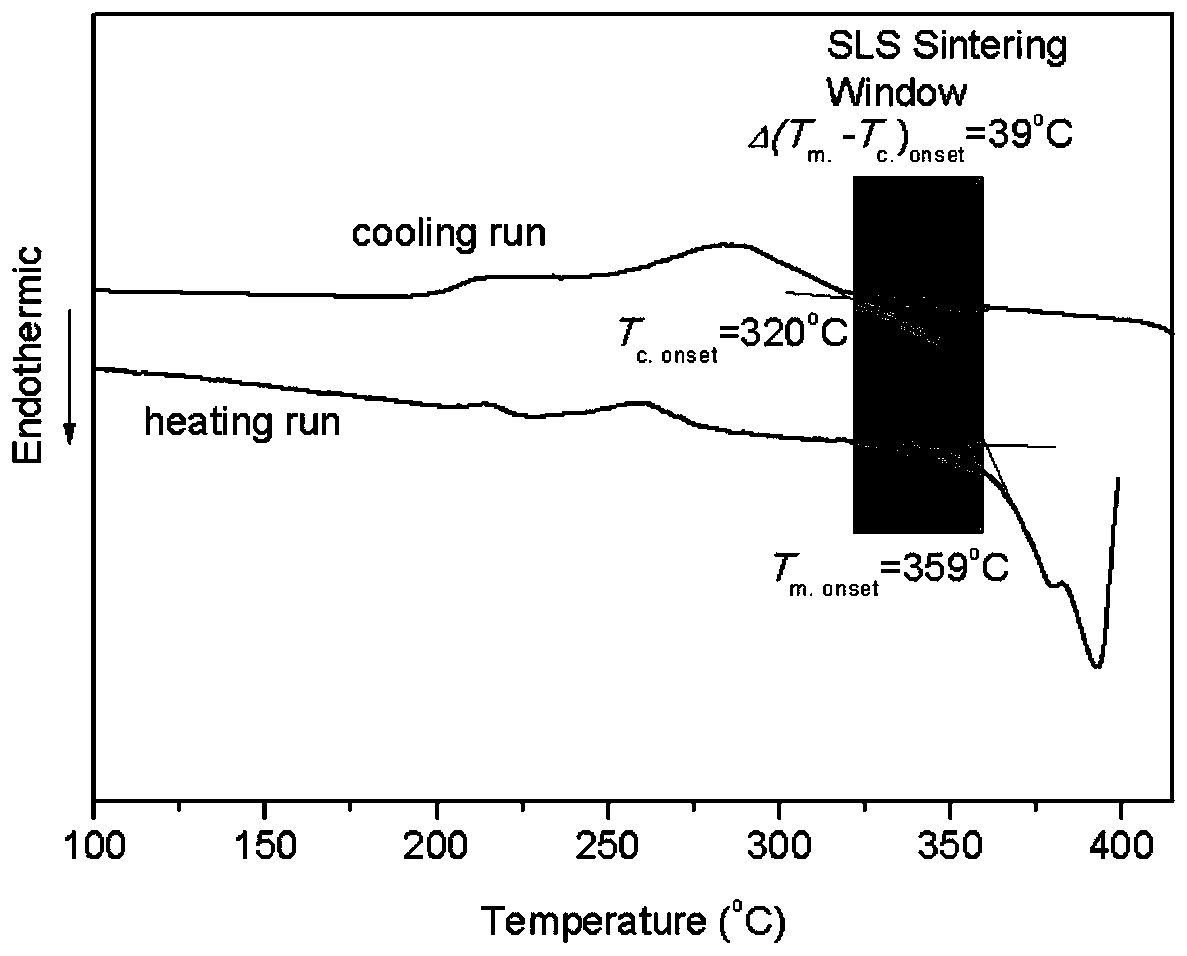

A polyimide powder and laser sintering technology, which is applied in the direction of additive processing, etc., can solve problems such as high melt viscosity, no crystallinity, no fixed melting temperature and sintering window

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] A polyimide powder material for selective laser sintering, which consists of (by weight):

[0042] ① 100 parts of crystalline polyimide resin powder (synthesized from the following aromatic dianhydride monomers, aromatic diamine monomers, and end-capping agents, and the aromatic dianhydride monomers are 3,3',4,4'- 55 parts of triphenyl ether tetra-acid dianhydride, 32 parts of 1,4-bis(4'-aminophenoxy)benzene and 12 parts of 3,4'-diaminodiphenyl ether as aromatic diamine, end-capping agent It is 1 part of terephthalic anhydride, and the number average molecular weight of the resin is 25000g / mol)

[0043] ②0.3 parts of polyphenylene sulfide resin powder [coating grade, melt index (316℃ / 5kg) is 1700g / 10min, particle size is 10μm-150μm spherical powder solid]

[0044] ③0.5 part of antioxidant (0.3 part of antioxidant 1010 and 0.2 part of antioxidant 168)

[0045] The preparation method of the polyimide powder material for selective laser sintering:

[0046] (1) Cool the ...

Embodiment 2

[0052] A polyimide powder material for selective laser sintering, which consists of (by weight):

[0053] ① 90 parts of crystalline polyimide resin powder (synthesized from the following aromatic dianhydride monomers and aromatic diamine monomers, the aromatic dianhydride monomer is 3,3',4,4'-triphenylene ether 56 parts of tetra-acid dianhydride, 32 parts of 1,3-bis(4'-aminophenoxy)benzene and 10 parts of 3,4'-diaminodiphenyl ether as the aromatic diamine monomer, and homogeneous 2 parts of phthalic anhydride, resin number average molecular weight 25000g / mol)

[0054] ② 2 parts polyphenylene sulfide resin powder [coating grade, melt index (316℃ / 5kg) is 1700g / 10min, particle size is 10μm-150μm spherical powder solid]

[0055] ③ 10 parts of nano silicon dioxide

[0056] ④ Antioxidant 0.5 part (antioxidant 1010 0.4 part and antioxidant 168 0.1 part)

[0057] The preparation method of the polyimide powder material for selective laser sintering:

[0058] (1) Cool the polyimide ...

Embodiment 3

[0064] A polyimide powder material for selective laser sintering, which consists of (by weight):

[0065] ① 90 parts of crystalline polyimide resin powder (synthesized from the following aromatic dianhydride monomers and aromatic diamine monomers, the aromatic dianhydride monomer is 3,3',4,4'-triphenylene ether A mixture of 8.5 parts of tetracarboxylic dianhydride and 35.5 parts of 3,3',4,4'-biphenyl tetracarboxylic dianhydride, the aromatic diamine monomer is 1,3-bis(4'-aminophenoxy)benzene 44.5 parts, the end-capping agent is 1.5 parts of terephthalic anhydride, and the number average molecular weight of the resin is 20000g / mol)

[0066] ② 2 parts polyphenylene sulfide resin powder [coating grade, melt index (316℃ / 5kg) is 1700g / 10min, particle size is 10μm-150μm spherical powder solid]

[0067] ③Carbon nanotubes 10 parts

[0068] ④ 0.5 parts of antioxidant (0.2 parts of antioxidant 1010 and 0.3 parts of antioxidant 168)

[0069] The preparation method of the polyimide pow...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com