Method of increasing melting temperature of Fischer-Tropsch wax by leaching

A technology of melting temperature and Fischer-Tropsch wax, which is applied in the field of increasing the melting temperature of n-alkane mixtures and raising the melting temperature of Fischer-Tropsch wax by leaching, which can solve the problems of inability to meet the quality requirements of high-end Fischer-Tropsch wax, wide melting temperature range of Fischer-Tropsch wax, Unsatisfactory sweating effect and other problems, to achieve the effect of easy adjustment of output size, avoiding adverse effects, and narrow melting range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

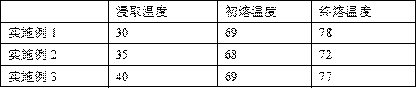

[0025] Embodiment 1, the filter paper is folded into a cylindrical cup with an outer diameter of 2 centimeters, and fixed on the outer surface with a metal wire, which is called a self-made filter paper cup, and as a container for extraction experiments, a particle diameter of 60 ± 39 microns is taken by weighing 40# Put 5.0 grams of Fischer-Tropsch wax in a homemade filter paper cup, put it into a glass bottle with an inner diameter of 2.5 cm, inject 15.0 grams of n-heptane, and immerse the Fischer-Tropsch wax solid in n-heptane, seal the glass bottle, and then Put it in a constant temperature water bath at 30°C, extract the liquid in the sealed glass bottle after leaching for 2 hours, add 15.0 g of n-heptane, continue leaching for 2 hours, take out the self-made filter paper cup, and remove the undissolved Fischer-Tropsch wax Distill and recover n-heptane to obtain high melting temperature Fischer-Tropsch wax; combine the n-heptane solutions obtained twice to distill and reco...

Embodiment 2

[0026] Embodiment 2, the filter paper is folded into a cylindrical cup with an outer diameter of 2 centimeters, and fixed on the outer surface with a metal wire, which is called a self-made filter paper cup, and as a container for extraction experiments, a particle diameter of 60 ± 39 microns is taken by weighing 40# Put 5.0 grams of Fischer-Tropsch wax in a self-made filter paper cup, then put it into a glass bottle with an inner diameter of 2 cm, inject 20.0 grams of n-heptane, immerse the Fischer-Tropsch wax solid in n-heptane, seal the glass bottle, and then Put it in a constant temperature water bath at 35°C, soak for 2 hours, take out the self-made filter paper cup, take out the undissolved Fischer-Tropsch wax, distill and recover n-heptane to obtain Fischer-Tropsch wax with high melting temperature; It is the raffinate, distilled and recovered n-heptane to obtain low melting temperature Fischer-Tropsch wax. The recovered n-heptane is recycled. Take a small amount of Fi...

Embodiment 3

[0027] Embodiment 3, the filter paper is folded into a cylindrical cup with an outer diameter of 2 centimeters, and fixed on the outer surface with a wire, called a self-made filter paper cup, as a container for extraction experiments, weighing 40# with a particle diameter of 60 ± 39 microns Put 5.0 grams of Fischer-Tropsch wax in a self-made filter paper cup, then put it into a glass bottle with an inner diameter of 2 cm, inject 20.0 grams of n-heptane, immerse the Fischer-Tropsch wax solid in n-heptane, seal the glass bottle, and then Put it in a constant temperature water bath at 40°C, soak for 2 hours, take out the self-made filter paper cup, take out the undissolved Fischer-Tropsch wax, evaporate and recover n-heptane, and obtain high melting temperature Fischer-Tropsch wax; Distill and recover n-heptane to obtain low melting temperature Fischer-Tropsch wax. The recovered n-heptane is recycled. Take a small amount of Fischer-Tropsch wax with high melting temperature, and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com