Method and device for producing refined anthracene, refined carbazole and phenanthrene product from raw material of monoanthracene oil

A technology for refining carbazole and anthracene oil, which is applied in the field of coal tar deep processing technology in metallurgical coking industry, can solve the problems of limited production capacity, high import cost, increased crystallization time, etc., and achieves low solvent consumption, low pollution and high product purity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

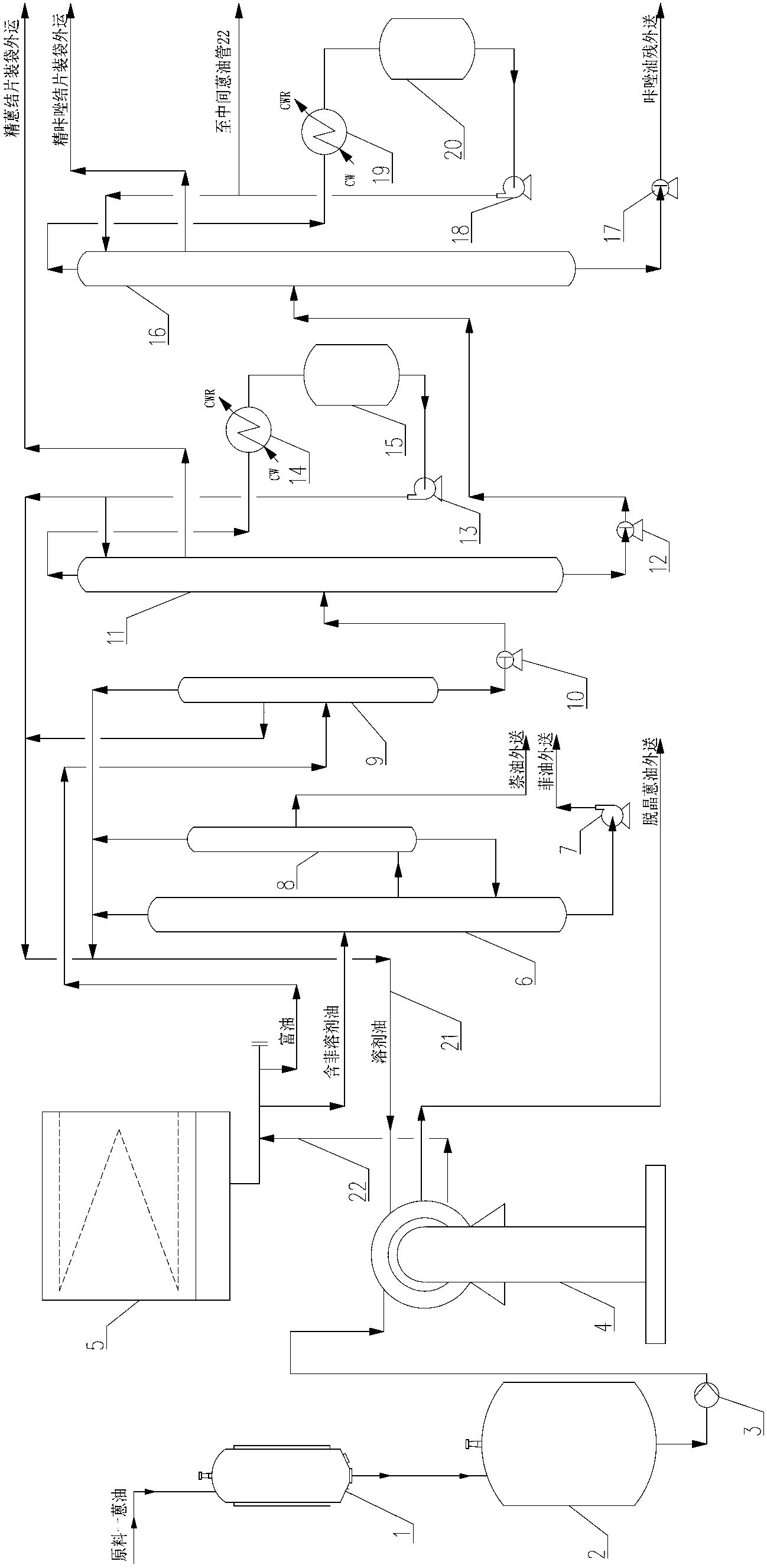

[0026] See figure 1 , is a structural schematic diagram of an embodiment of a device for producing refined anthracene, refined carbazole and phenanthrene products using anthracene oil as a raw material, including a stirring cooler 1, a slurry circulation tank 2, a slurry circulation pump 3, a centrifuge 4, and a crystallization box 5. Solvent distillation tower 6, concentration tower 9, anthracene tower 11 and carbazole tower 16, stirring cooler 1 is connected with slurry circulation tank 2, slurry circulation pump 3, centrifuge 4, crystallization box 5 in turn, crystallization box 5 The oil-rich pipeline is connected to the entrance of the middle section of the enrichment tower 9, and the phenanthrene-containing solvent oil pipeline of the crystallization tank 5 is connected to the entrance of the middle section of the solvent distillation tower ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com