Method for adsorbing-crystal separation of paraxylene and ethylbenzene from C8 aromatic

A p-xylene, adsorption separation technology, applied in the direction of adsorption purification/separation, crystallization purification/separation, organic chemistry, etc., can solve problems such as xylene crystallization separation that are not mentioned, and achieve the effect of increasing the processing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0030] An adsorbent for separating mixed xylenes used in the present invention was prepared.

[0031] Mix ZSM-5 zeolite (produced by Shanghai Xinnian Petrochemical Auxiliary Co., Ltd.) with a silica / alumina molar ratio of 200 and kaolin at a mass ratio of 90:10, roll into a ball, roast at 500°C for 4 hours, and sieve the pellets The particle diameter is 0.4~0.8 millimeter, obtains adsorbent A.

example 2

[0033] Mix X zeolite (produced by Shanghai Xinnian Petrochemical Auxiliary Co., Ltd.) and kaolin at a mass ratio of 90:10, roll into a ball, bake at 500°C for 4 hours, take spherical particles of 0.4-0.8 mm, and add tetramethoxysilane Cyclohexane solution, the mass ratio of spherical particles: tetramethoxy silicon: A cyclohexane is 1:10:10, stirred and contacted at 25°C for 2 hours, the spherical particles were taken out, dried at 50°C for 4 hours, and dried at 500°C After firing for 4 hours, the silicon oxide content of the spherical particles after silicone treatment increased from 44.6% by mass to 46.2% by mass. Then carry out ion exchange with the mixed solution of barium nitrate and potassium chloride, the liquid / solid volume ratio of solution and spherical particle is 10, and the concentration of barium nitrate and potassium chloride in the solution is respectively 6 mass % and 1 mass %, after exchange The solid was dried at 120°C for 4 hours and activated at 200°C for ...

example 3

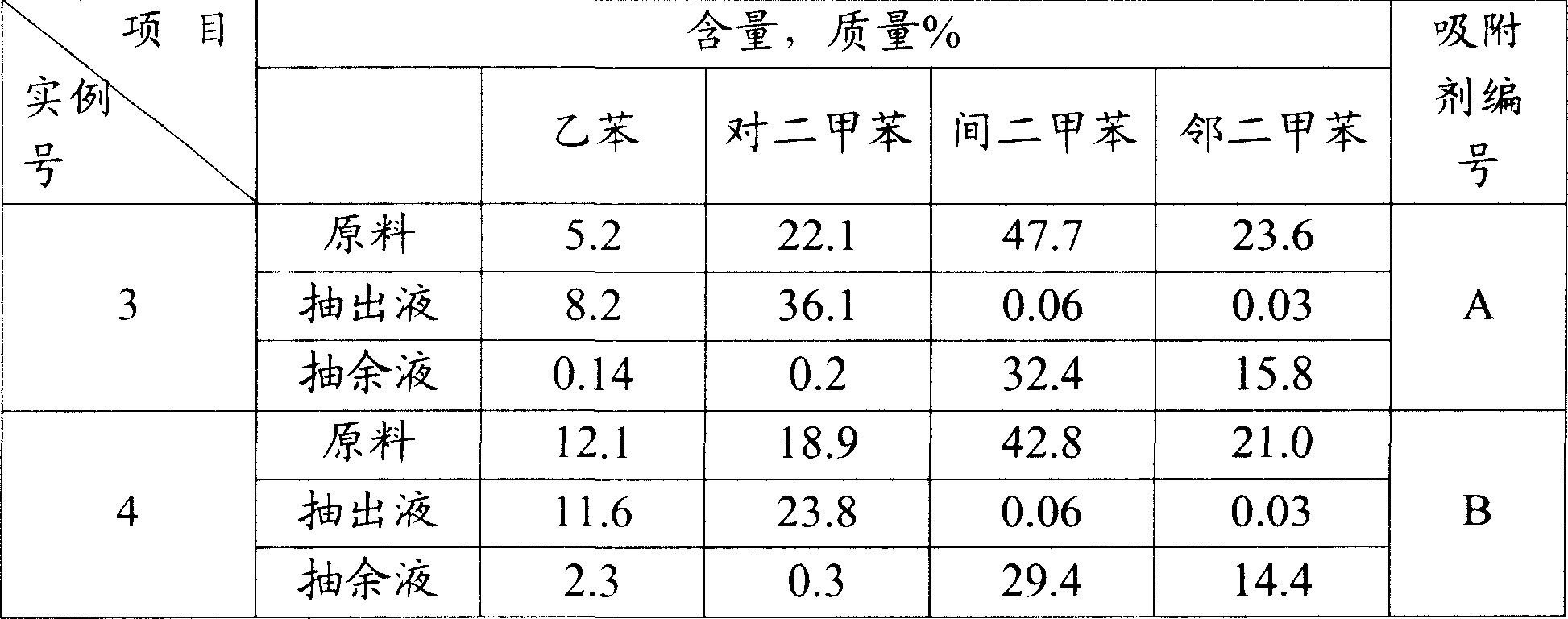

[0035] Adsorption and separation of mixed xylenes.

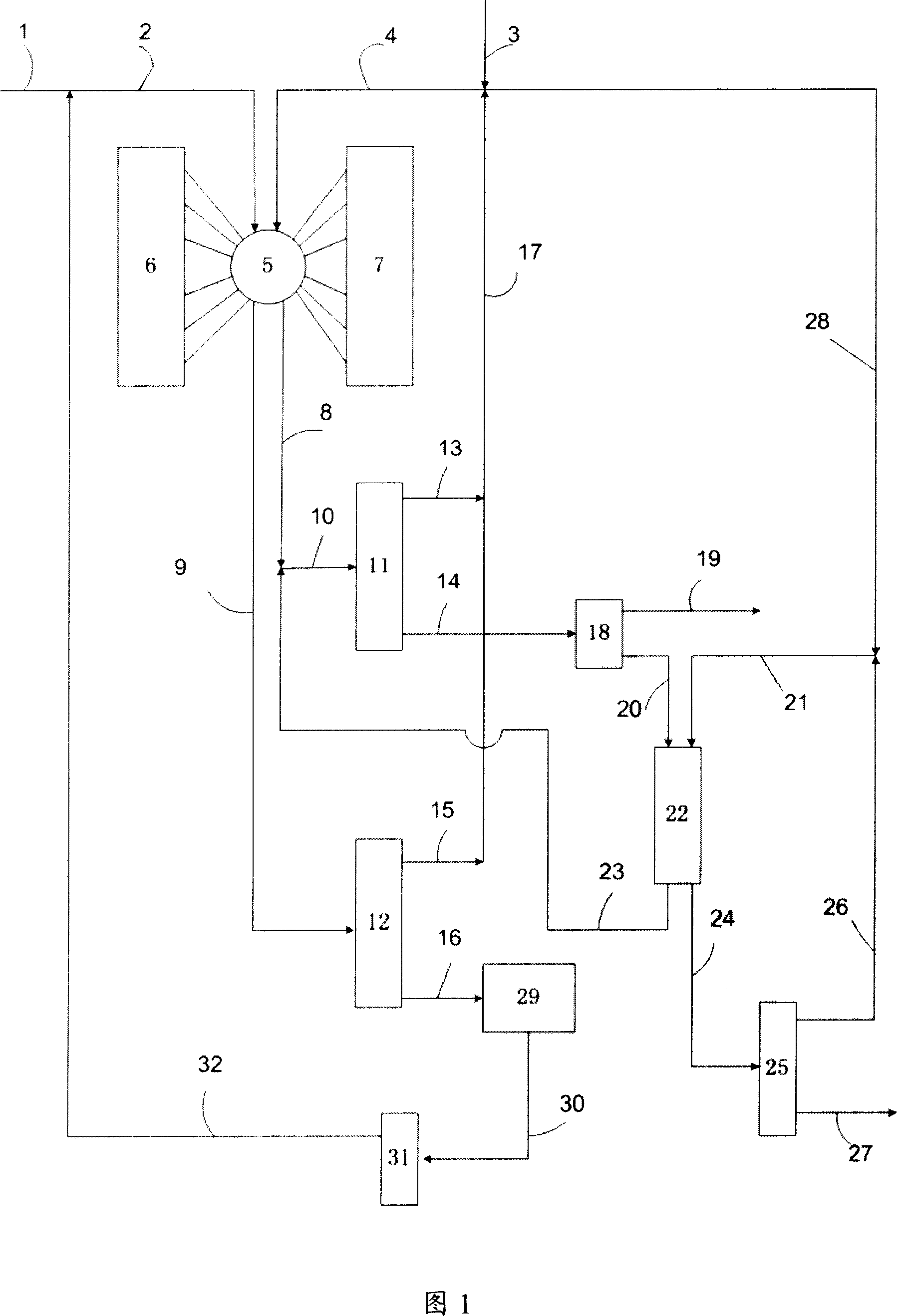

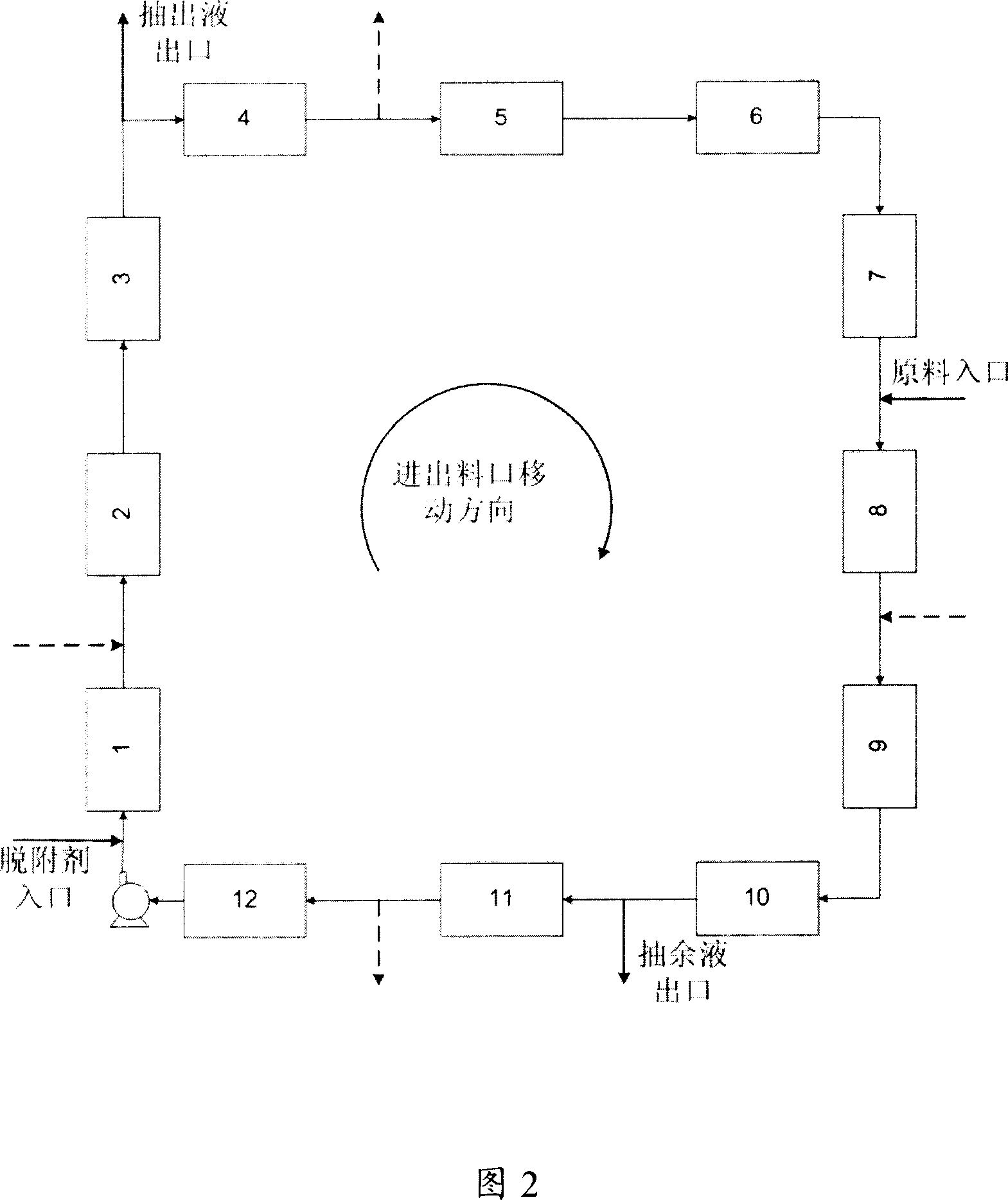

[0036] Use a set of small simulated moving bed equipment, as shown in Figure 2. It is composed of 12 columns connected in series. The cavity containing the adsorbent inside each column is 200mm high and 40mm in diameter. The 12th column is connected to the first column through a pump to circulate the fluid in the column. The connections of each column are uniform. Import and export of materials. The number of adsorption columns required for each stage of adsorption separation is set according to the following method: 3 columns with interval numbers of 8, 9, and 10 between the raw material inlet and the raffinate outlet are the adsorption sections; the raffinate outlet and the desorbent The two columns numbered 11 and 12 between the inlets are the isolation section; the three columns numbered 1, 2, and 3 between the desorbent inlet and the outlet of the extract are the desorption section; the outlet of the extract and the T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com