Method for extracting fluorene, anthracene and carbazole from mixed anthracene oil

A technology of anthracene oil and carbazole, applied in organic chemistry, distillation purification/separation, crystallization purification/separation, etc., to achieve the effect of stable work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

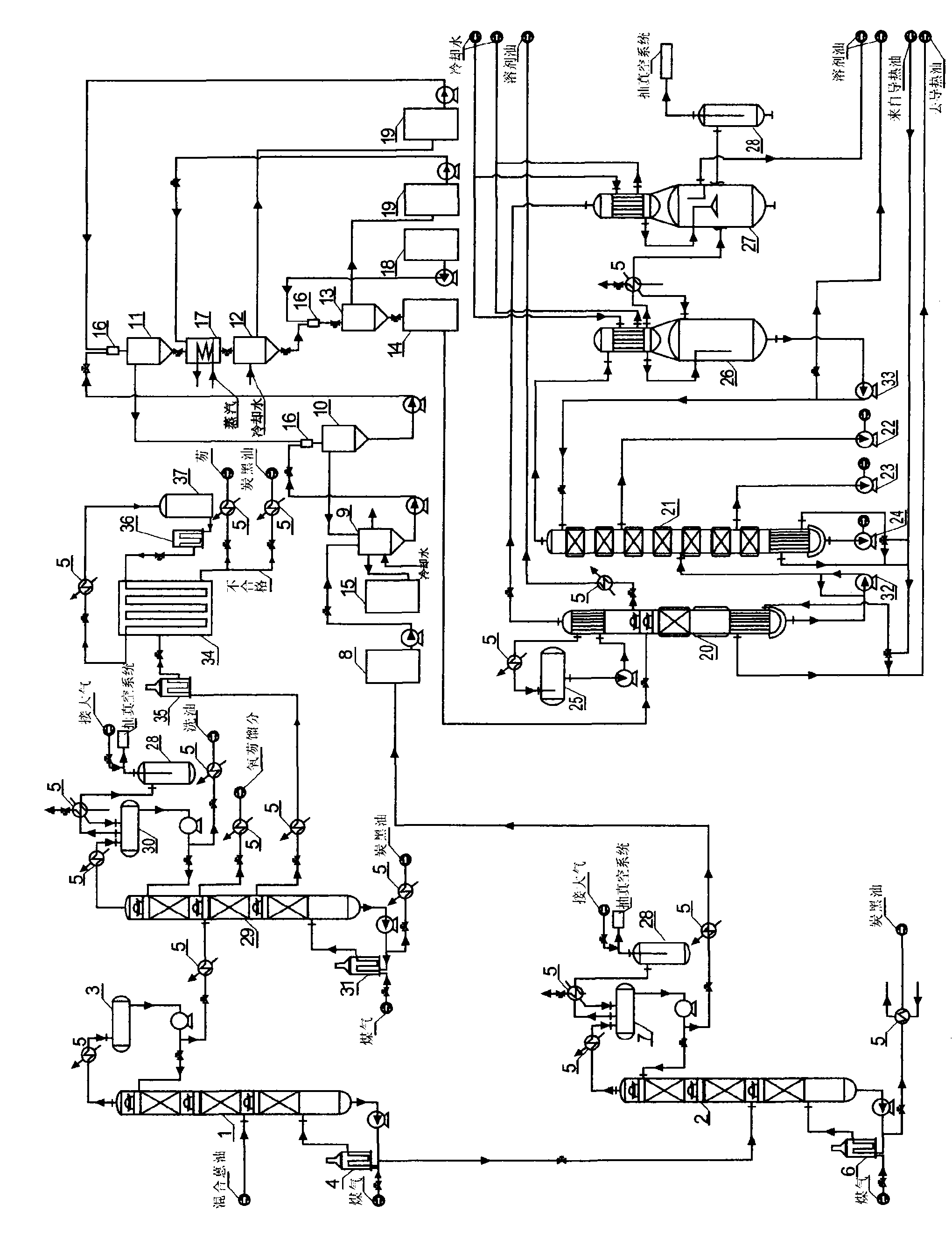

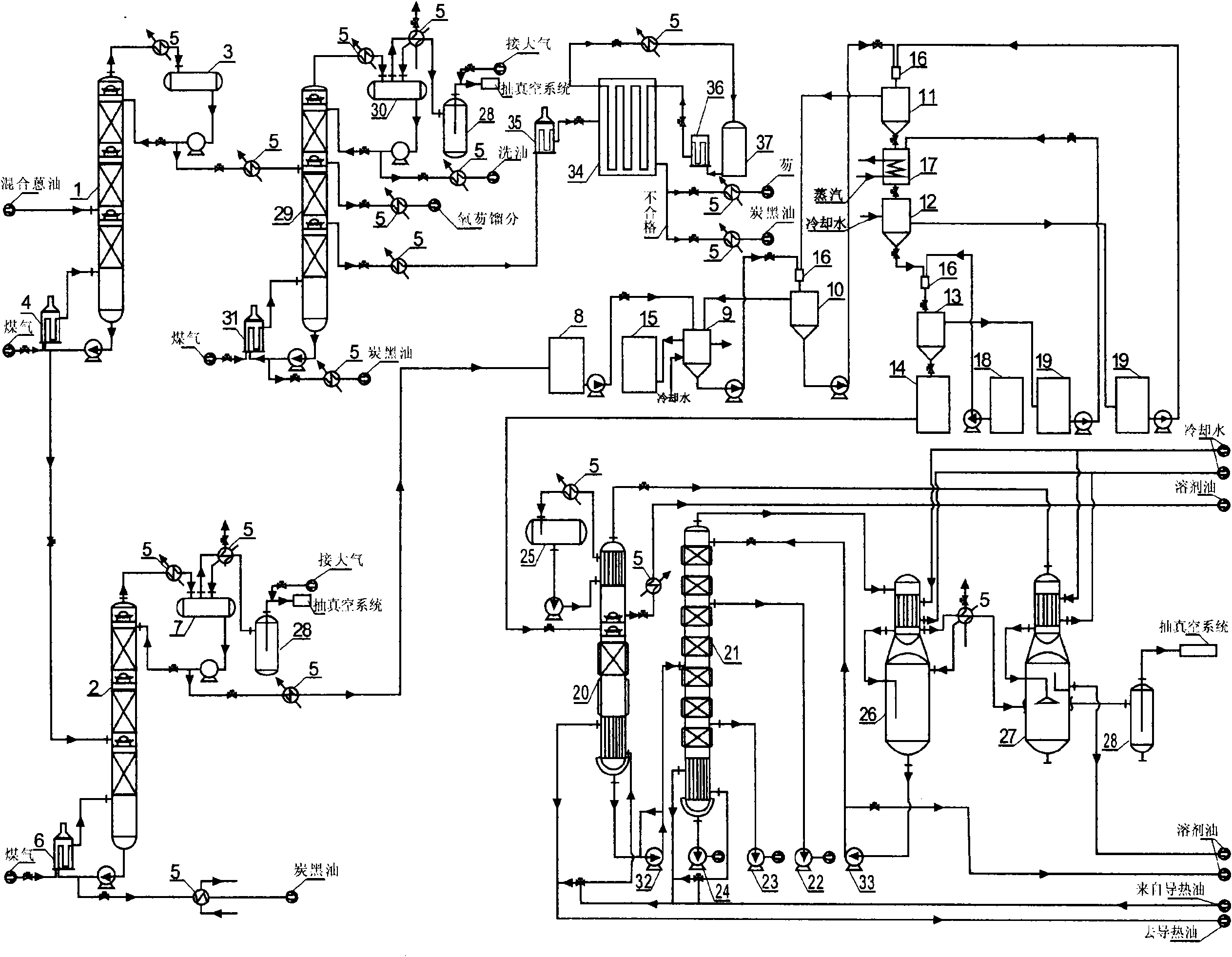

Image

Examples

Embodiment 1

[0026] A. Rectification of mixed anthracene oil: The raw material mixed anthracene oil contains 6% acenaphthene, 4% oxyfluorene, 9% fluorene, 25% phenanthrene, 6% anthracene and 3% carbazole, and the flow rate of the raw material is 6253kg / h. After being heated to 150°C by the heating furnace of the oil washing tower, it enters the oil washing tower; the pressure at the top of the oil washing tower is 100kPa, the temperature is 260°C, the flow rate of the oil washing fraction is 1630kg / h, and the composition is 22% acenaphthene, oxygen Fluorene 14%, fluorene 32%; the washing oil fraction enters the fluorene tower, the pressure at the top of the fluorene tower is 20kPa, the temperature is 145°C, the flow rate of the naphthalene and methylnaphthalene fractions before the extraction of oxyfluorene is 455kg / h, and the fluorene The temperature of the upper side line of the tower is 185°C, the flow rate of the extracted fluorene fraction is 507kg / h, the temperature of the lower side ...

Embodiment 2

[0031] A. Rectification of mixed anthracene oil: the same raw material mixed anthracene oil as in Example 1, with a flow rate of 6350 kg / h. After preheating to 140°C, it enters the oil washing tower, the pressure at the top of the oil washing tower is 105kPa, the temperature is 265°C, and the flow rate of the extracted oil washing fraction is 1550kg / h; the washing oil fraction enters the fluorene tower, the fluorene tower The top pressure is controlled at 22kPa, the temperature is 148°C, the flow rate is 428kg / h, the temperature of the upper side line of the fluorene tower is 189°C, and the flow rate of the extracted fluorene distillate is 404kg / h; the temperature of the lower side line of the fluorene tower is 203°C, and the fluorene fraction is extracted The flow rate is 412kg / h; the operating temperature at the bottom of the fluorene tower is 212°C, and the flow rate of the extracted carbon black oil fraction is 306kg / h; the pressure at the bottom of the oil washing tower is...

Embodiment 3

[0036] A. Rectification of mixed anthracene oil: the same raw material mixed anthracene oil as in Example 1, with a flow rate of 5050 kg / h. After preheating to 130°C, it enters the oil washing tower, the pressure at the top of the tower is 100kPa, the temperature at the top of the tower is 260°C, and the flow rate of the washed oil fraction is 1200kg / h; the washed oil fraction enters the fluorene tower, and the top of the fluorene tower The pressure is controlled at 18kPa, the operating temperature is 150°C, the flow rate is 235kg / h, the temperature of the upper side line of the fluorene tower is 190°C, and the flow rate of the dioxyfluorene fraction is 351kg / h; the temperature of the lower side line of the fluorene tower is 198°C, and the flow rate of the extracted fluorene fraction is The operating temperature at the bottom of the fluorene tower is 210°C, the flow rate is 185kg / h, and the carbon black oil fraction is produced; the pressure at the bottom of the oil washing tow...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com