Preparation method of m-trifluoromethylphenol

A technology of trifluoromethyl phenol and trifluoromethyl aniline, which is applied in the field of preparation of m-trifluoromethyl phenol, can solve the problems of high safety risk, long reaction time, low purity and the like, and achieves improved reaction yield and economical efficiency. Purification energy consumption and cost, the effect of reducing by-products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1-37

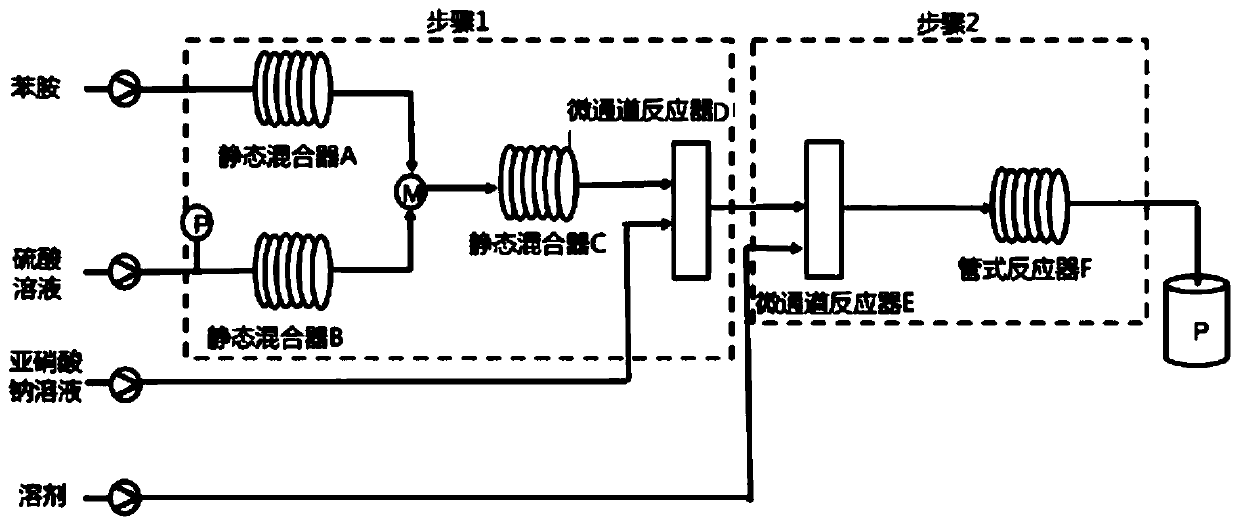

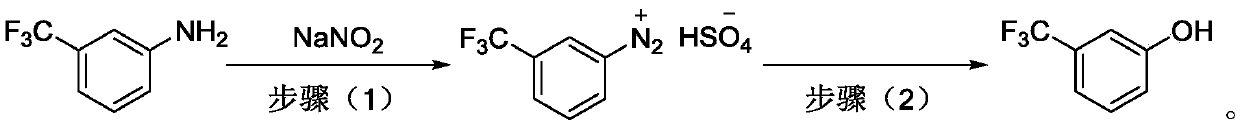

[0052] The aqueous solution of sulfuric acid and the aniline compound (1 equivalent) are respectively pumped into static mixers A and B at corresponding flow rates, and mixed into static mixer C at a certain temperature for salt-forming reaction to obtain a homogeneous mixture. After the gained mixture flows out from the static mixer C (the flow velocity here is the sum of A and B), the aqueous solution of nitrite enters the microchannel reactor D with the corresponding flow velocity and mixes respectively and the diazotization reaction takes place to obtain Solution of diazonium salt. The solution of gained diazonium salt flows out from microchannel reactor D (the flow velocity here is the sum of A, B and C three) and enters in microchannel reactor E with corresponding flow velocity respectively with organic solvent and mixes, After uniform mixing, it flows out from the microchannel reactor E, and flows into the tubular reactor F at a certain temperature to undergo hydrolysis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com