Composite material and preparation method thereof

A technology of composite materials and substrates, applied in electrolytic coatings, coatings, surface reaction electrolytic coatings, etc., to achieve beautiful decorative effects and increase value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

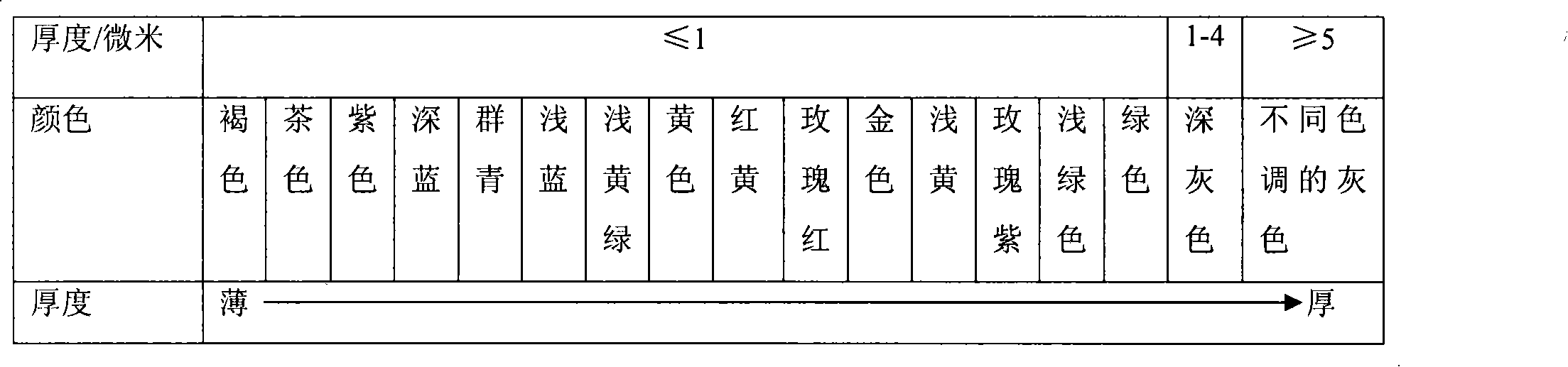

[0017] The preparation method of the composite material provided by the present invention includes forming an oxide film layer with uneven thickness on at least one metal surface of the substrate, and the oxide film layer has different colors with different thicknesses.

[0018] According to the preparation method provided by the present invention, preferably, the oxide film layer is formed by anodic oxidation; the metal is pure titanium or titanium alloy.

[0019] According to the preparation method provided by the present invention, preferably, the anodic oxidation method includes, under anodic oxidation conditions, bringing at least one metal surface of the substrate into contact with an electrolyte, using the substrate as an anode, Anodizing is performed by using a conductive material that does not react with the electrolyte as a cathode, and the conditions of the anodizing are changed to make the thickness of the obtained anodized film layer uneven. Wherein, the cathode c...

Embodiment 1

[0039] Workpiece: 25×50mm pure titanium sheet

[0040] 1. Pretreatment

[0041] (1) polishing

[0042] Using electrochemical polishing, immerse the workpiece in the electrolyte at 20°C as the anode, and use stainless steel as the cathode, at 30A / dm 2 Under the current density, electrolysis for 3 minutes for polishing, so that the workpiece can obtain a smooth and bright surface. Among them, the electrolytic solution is an aqueous solution containing 40% by weight of chromic anhydride and 10% by weight of hydrofluoric acid.

[0043] Clean the workpiece with clean water after polishing.

[0044] (2) Sandblasting

[0045] The 9060 (7660) SA sandblasting machine produced by Dongguan Jichuan Machinery Equipment Co., Ltd. was used to sandblast the polished workpiece. Clean the workpiece with clean water after sandblasting.

[0046] (3) Degreasing

[0047] At room temperature, immerse the sandblasted workpiece in a chemical degreasing solution for 5 minutes for degreasing. The...

Embodiment 2

[0068] Workpiece: 25×50mm pure titanium sheet

[0069] 1. Pretreatment

[0070] The workpiece was pretreated according to the pretreatment method described in Example 1.

[0071] 2. Anodizing

[0072] Contain electrolytic solution in electrolyzer, the electrolytic solution that adopts is identical with embodiment 1.

[0073] Immerse the workpiece after the above pretreatment in the electrolyte of the electrolytic cell, take the workpiece as the anode, and use the stainless steel plate as the cathode, the initial voltage is 30V, the end voltage is 45V, the boosting time is 50 seconds, and in the electrolytic solution Anodizing is carried out at a temperature of 25°C, while the workpiece is moved upwards from the electrolyte into the air at a speed of 1mm / sec. When anodizing for 50 seconds, the workpiece is completely removed from the electrolyte, and the reaction is over.

[0074] Take out the workpiece and clean it.

[0075] 3. Post-treatment of anodized film layer

[00...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com