Automatic sawtooth transverse cutter

A cross-cut knife and sawtooth technology, applied in the field of fabric cutting, can solve the problems of increased labor costs, high labor intensity, and easy yarn detachment, and achieve the effects of high cost, easy maintenance, and low cost of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

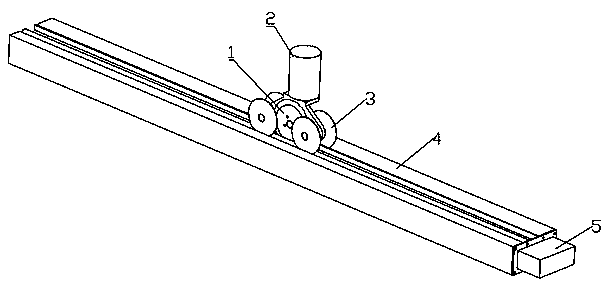

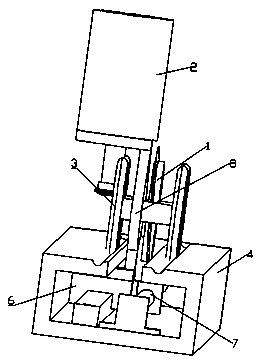

[0026] An automatic sawtooth cross-cutting knife, comprising a bevel rotary cutter 1, a cutter motor 2, a cloth pressing wheel 3 and a guide rail base 4, the guide rail base 4 is provided with a guide rail, and the bevel rotary cutter 1 is fixed on a slider 6 and the bevel rotary cutter 1 is driven by the cutter motor 2, the slider 6 is slidably installed on the guide rail, one end of the guide rail base 4 is installed with a screw motor 5 and the output end of the screw motor 5 is connected with the screw 7, The screw rod 7 is connected with the bracket 8 through the slider 6, and the connection is firm and the operation synchronization is good. The power line of the cutter motor 2 is arranged in the guide rail base 4 and can move with the bracket 8, avoiding the trouble of the traditional cutter motor 2. The unsafeness of the power cord hanging outside and the interference to the work, the pressure cloth wheel 3 is pressed on the groove of the guide rail base 4.

[0027] The...

Embodiment 2

[0031] An automatic sawtooth cross-cutting knife, comprising a bevel rotary cutter 1, a cutter motor 2, a cloth pressing wheel 3 and a guide rail base 4, the guide rail base 4 is provided with a guide rail, and the bevel rotary cutter 1 is fixed on a slider 6 and the bevel rotary cutter 1 is driven by the cutter motor 2, the slider 6 is slidably installed on the guide rail, one end of the guide rail base 4 is installed with a screw motor 5 and the output end of the screw motor 5 is connected with the screw 7, The screw rod 7 is connected with the slider 6, and the screw rod motor 5 drives the screw rod 7 to rotate, so as to automatically push the inclined-plane rotary cutter 1 forward without manual push, which reduces the labor intensity. On the groove, tension and pressure can be generated on the cut fabric to make it even and tense, which is convenient for the inclined-plane rotary cutter 1 to cut smoothly.

[0032] This product can also be equipped with an automatic liftin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com