Water-borne epoxy anti-corrosion paint and preparing method thereof

An anti-corrosion coating, water-based epoxy technology, applied in anti-corrosion coatings, epoxy resin coatings, alkali metal silicate coatings, etc., can solve the problem of increasing construction difficulty and controllability of quality, low solid content of formulations, and high VOCs content problem, to achieve the effect of increasing the anti-skid and anti-migration effect, the production process is simple and convenient, and the effect of increasing the surface roughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] A water-based epoxy anti-corrosion coating, including component A (water-based epoxy silicate solution) and component B (dry powder mixture), and when used, the weight ratio of component A to component B is 1:2 be mixed; wherein the component A includes in parts by weight: 30 parts of water-based epoxy resin emulsion, 18 parts of potassium silicate, 18 parts of lithium silicate, 1 part of water-based wetting and dispersing agent, and 15 parts of deionized water; Said component B includes by weight: 80 parts of zinc powder, 5 parts of corundum, 5 parts of antirust pigment;

[0033]Further, the water-based epoxy resin emulsion is a water-based polyoxyethylene grafted epoxy resin emulsion; since the base material will be corroded by ultraviolet rays, visible light, oxygen, chemical substances and microorganisms outdoors, by making full use of the complementary advantages between materials , water-based epoxy resin emulsion cooperates with other components to form a closed ...

Embodiment 2

[0047] A water-based epoxy anti-corrosion coating, including component A (water-based epoxy silicate solution) and component B (dry powder mixture), and when used, the weight ratio of component A to component B is 1:3 to be mixed;

[0048] The component A includes in parts by weight: 40 parts of water-based epoxy resin emulsion, 25 parts of potassium silicate, 25 parts of lithium silicate, 3 parts of water-based wetting and dispersing agent, and 25 parts of deionized water;

[0049] The component B includes, in parts by weight: 90 parts of zinc powder, 10 parts of corundum, 5 parts of filler, and 10 parts of antirust pigment.

[0050] Further, the water-based epoxy resin emulsion is a polyoxypropylene chain-end epoxy resin emulsion; since the base material will be corroded by ultraviolet light, visible light, oxygen, chemical substances and microorganisms outdoors, by making full use of the complementary advantages between materials, The water-based epoxy resin emulsion coope...

Embodiment 3

[0064] A water-based epoxy anti-corrosion coating, including component A (water-based epoxy silicate solution) and component B (dry powder mixture), and when used, the weight ratio of component A to component B is 1:3 to be mixed;

[0065] The component A includes: aqueous epoxy resin emulsion, potassium silicate, lithium silicate, aqueous wetting and dispersing agent, deionized water;

[0066] The component B includes: zinc powder, carborundum, filler, antirust pigment.

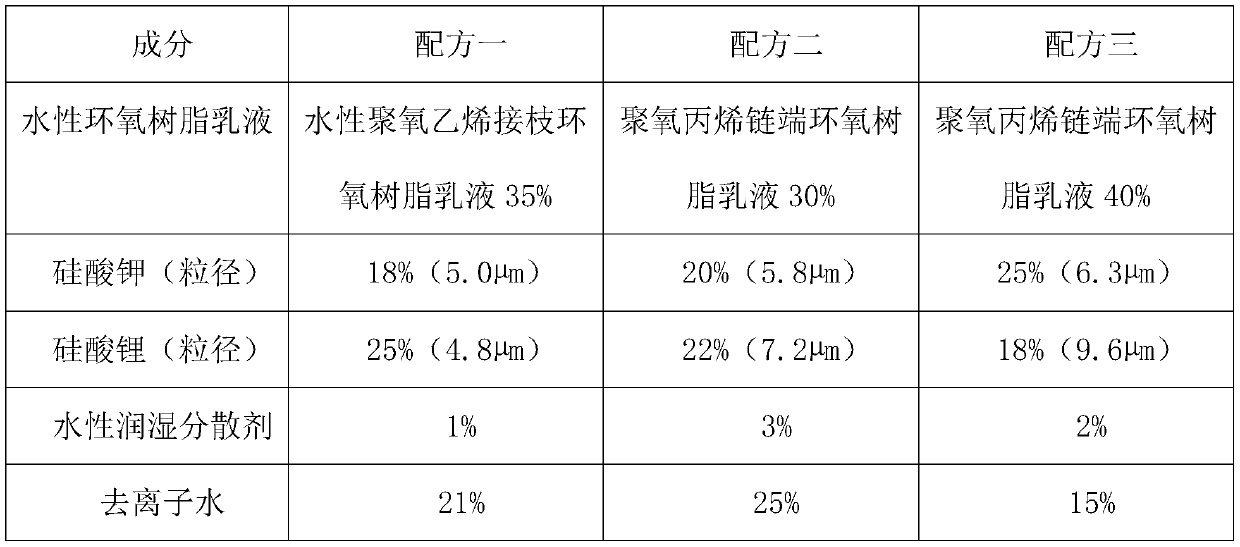

[0067] During specific implementation, the component A can refer to the formula in Table 1, and the percentages in Table 1 are all percentages by mass; when used, it is necessary to prepare component A in advance according to the formulas of component A in Table 1. ;

[0068] Different ratios of raw materials in component A of table 1

[0069]

[0070] During specific implementation, the component B can refer to the formula in Table 2, and the percentages in Table 2 are all mass percentages; when in us...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com