Glass curtain wall and dismounting method thereof

A glass curtain wall and panel technology, applied in the direction of walls, building maintenance, building components, etc., can solve the problems of inconvenient disassembly and assembly, unable to install or adjust glass panels independently, not suitable for quick installation and post-construction maintenance and adjustment, etc. , High decorative effect, easy to disassemble and assemble separately

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

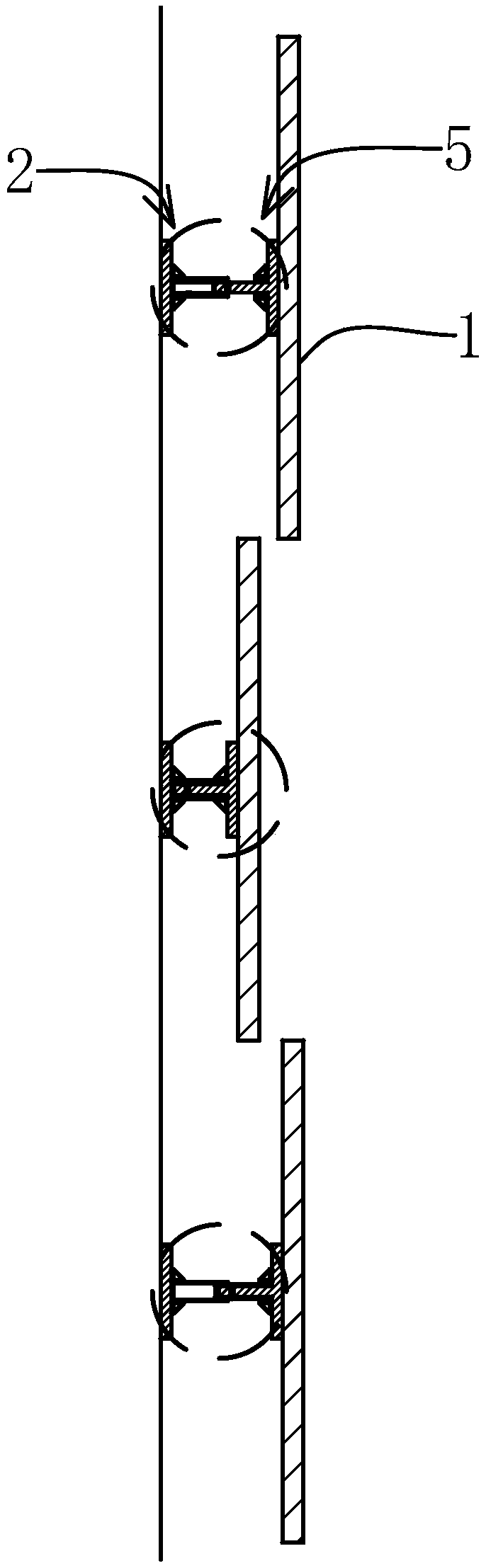

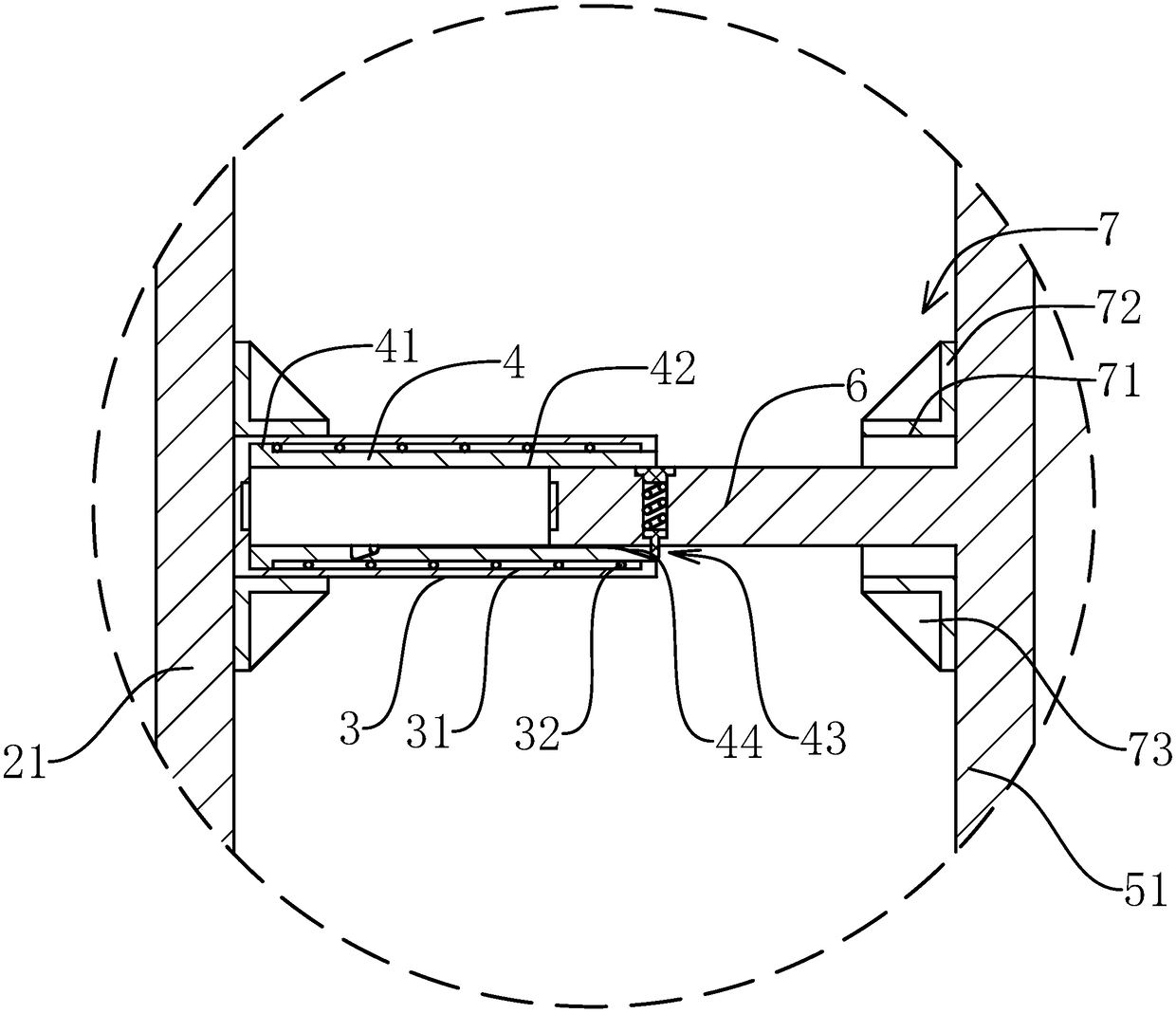

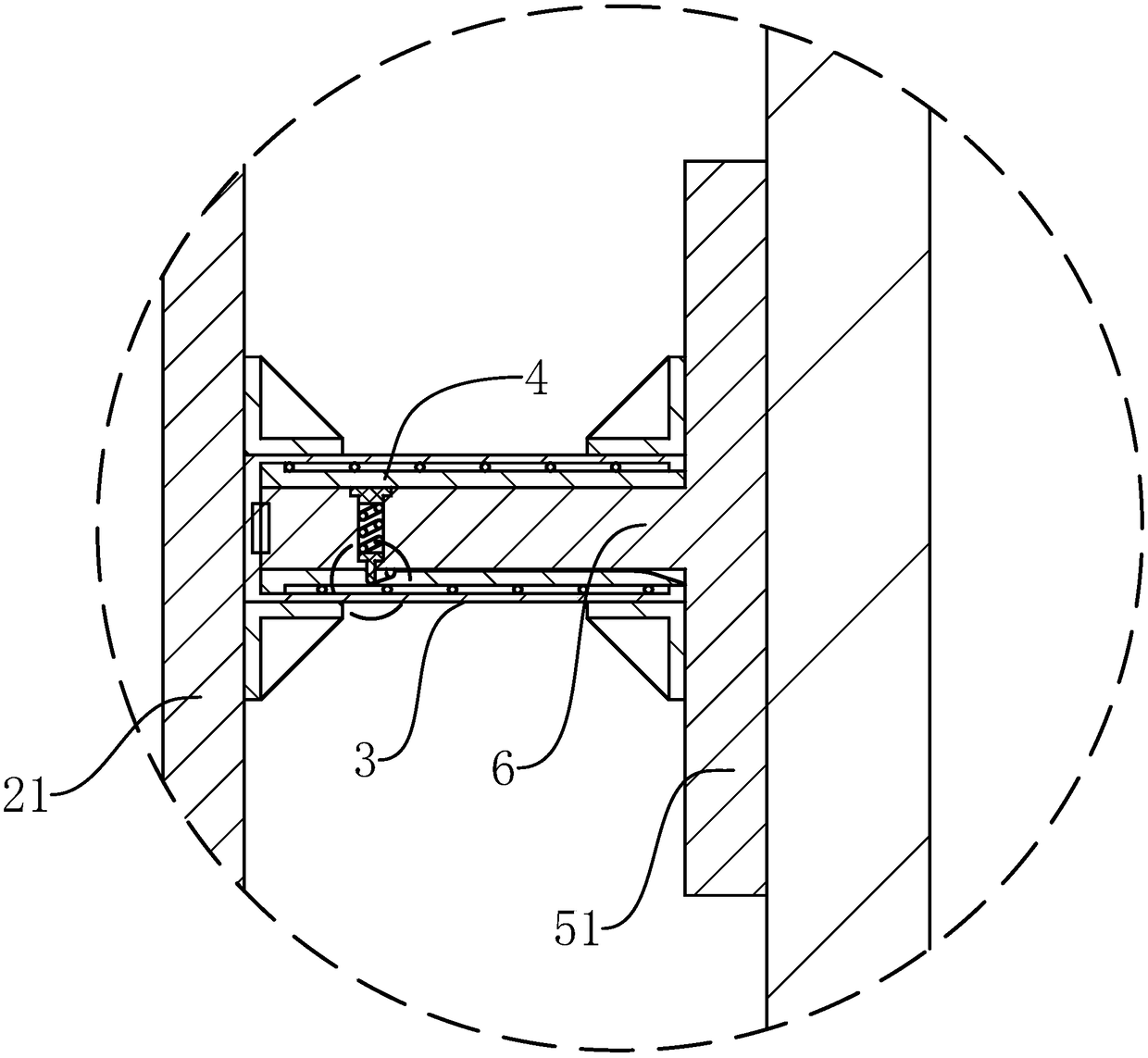

[0042] Such as Figure 1-6 As shown, a glass curtain wall of the present invention includes a fixed seat 2 fixed to the wall and a plurality of rectangular glass panels 1 with connecting seats 5 on the rear side, the panels 1 are connected to the fixed seats 2 through the connecting seats 5, and the fixed seats 2 includes the fixed plate 21 that the rear side is fixed to the wall, and the front and rear sides of the fixed plate 21 are parallel, and also includes a circular sleeve-shaped inner fixed sleeve 4 and an outer fixed sleeve 3 on the outside of the inner fixed sleeve 4, and the outer fixed sleeve 3. The end is fixed on the front side of the fixed plate 21, and the axis of the outer fixed sleeve 3 is perpendicular t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com