Water-based woodware adhesive force-enhanced single-component matt modulation light-colored finishing coat

A single-component technology with enhanced adhesion, applied in the field of wood lacquers, can solve the problems of not meeting the construction requirements such as adhesion, poor color stability, good color stability, etc., to achieve improved construction performance and decorative performance, and film-forming efficiency Enhanced, good color stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

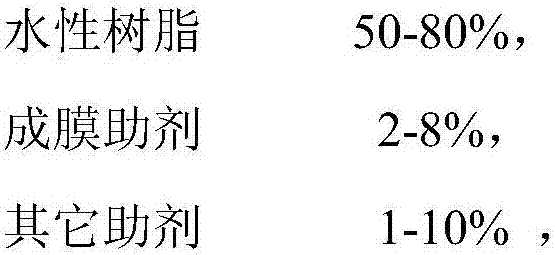

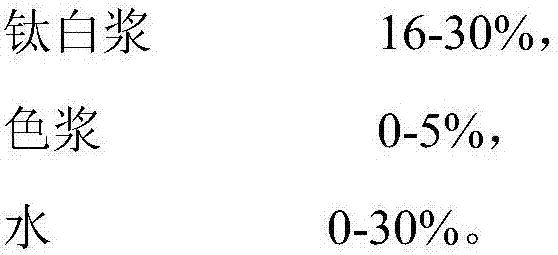

[0019] raw material

[0020] To prepare the topcoat, pass all the components through a disperser, disperse evenly, and pack to obtain the finished product. This implementation topcoat is ceramic white effect.

Embodiment 2

[0022] raw material

[0023] To prepare the topcoat, pass all the components through a disperser, disperse evenly, and pack to obtain the finished product. The top coat of this implementation is a creamy yellow effect.

Embodiment 3

[0025]

[0026]

[0027] To prepare the topcoat, pass all the components through a disperser, disperse evenly, and pack to obtain the finished product. The top coat in this implementation is a small powder effect.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com