Dry-type heat-insulating waterproof coating

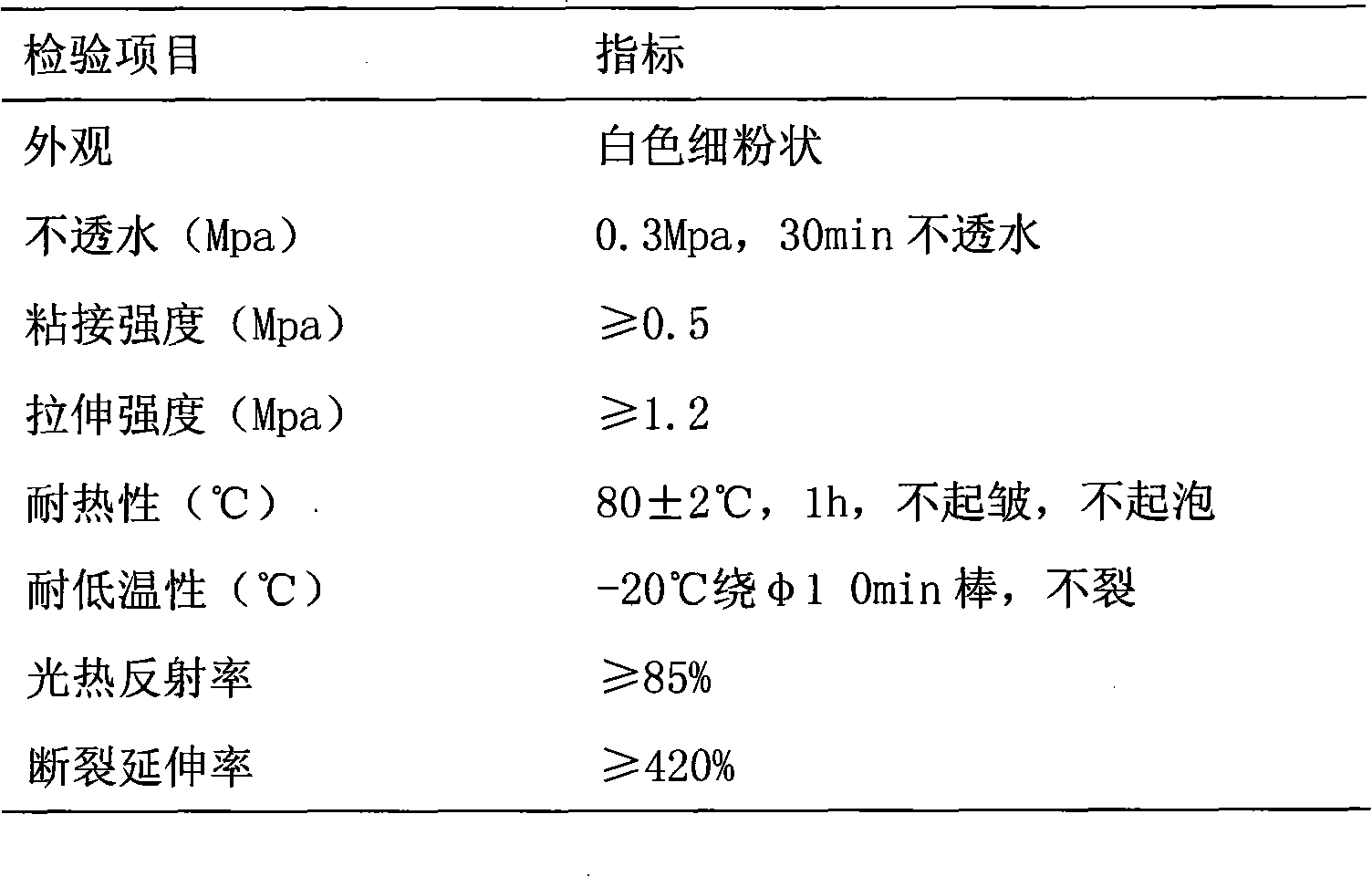

A waterproof coating and dry powder technology, applied in the coating field, can solve the problems of complex production process, easy aging of the coating, easy freezing and cracking, etc., and achieve the effects of high sunlight reflectivity, good waterproof performance, and good heat insulation and waterproofing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0061] Embodiment 1 A dry powder heat-insulating and waterproof coating is made of the following raw materials in weight percent:

[0062] SAE latex powder 1.5%, EVA latex powder 4%, hollow glass microspheres 10%, white quartz sand 10%, sepiolite powder 10%, diatomite powder 1%, attapulgite powder 4.5%, mica powder 8%, Heavy calcium powder 10%, light calcium powder 5%, rutile titanium dioxide 0.5%, lithopone 1%, talcum powder 10%, white cement 24%, additive tributyl phosphate 0.5%.

[0063] When preparing the above-mentioned dry powder heat-insulating and waterproof coating, first mix white quartz sand, sepiolite powder, diatomite, attapulgite, mica, heavy calcium powder, light calcium powder, rutile titanium dioxide, lithopone, talcum powder, white The cement is mixed and ground to an average particle size of ≥250 mesh, then sieved, then redispersible latex powder, hollow glass microspheres and additives are added and mixed evenly.

Embodiment 2

[0064] Embodiment 2 A dry powder heat-insulating and waterproof coating is made of the following raw materials in weight percent:

[0065] SAE latex powder 1%, hollow glass microspheres 15%, white quartz sand 8%, sepiolite powder 10%, diatomite powder 2%, attapulgite powder 3%, mica powder 5%, heavy calcium powder 14%, Light calcium powder 5%, rutile titanium dioxide 1%, talcum powder 10%, white cement 25%, organic silicon powder 0.3%, ultra-fine active dicyandiamide 0.7%.

[0066] The preparation method is basically the same as in Example 1.

Embodiment 3

[0067] Embodiment 3 A dry powder heat-insulating and waterproof coating is made of the following raw materials in weight percentage:

[0068] EVA latex powder 4%, hollow glass microspheres 14%, sepiolite powder 14%, diatomite powder 4%, attapulgite powder 2%, mica powder 8%, heavy calcium powder 11.2%, light calcium powder 10%, 1.5% rutile titanium dioxide, 0.5% lithopone, 10% talcum powder, 20% white cement, 0.8% ultra-fine active dicyandiamide.

[0069] The preparation method is basically the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| reflectance | aaaaa | aaaaa |

| whiteness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com