Solar battery module

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

[0109] Preparation Process

[0110] As shown in FIG. 1, a solar better cell-forming structure comprising a lower electrode layer 2, an amorphous silicon layer 3 having a pn junction or pin junction, an insulating layer 4, and an ITO transparent electrode layer 5 formed on a flexible substrate 1 was provided with a through-hole 10 and open channels 10a by laser machining.

[0111] Next, as shown in FIG. 2, a first isolating layer 6 and a second isolating layer 7 were formed over the ITO transparent electrode layer 5 where the open channels 10a were formed. Further, as shown in FIG. 3, a wiring electrode layer 8 was formed over the first isolating layer 6 and through-hole 10.

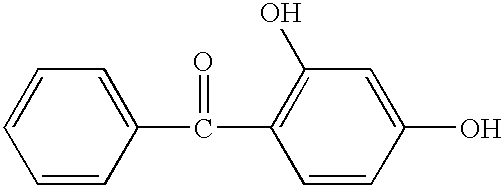

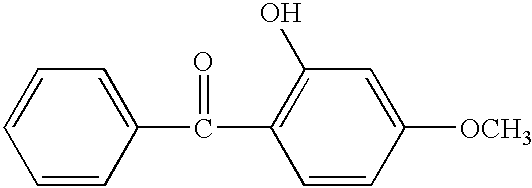

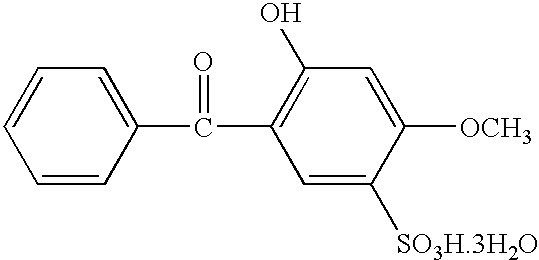

[0112] Next, as shown in FIG. 4, after a reverse-side lead-out electrode 9 was formed if necessary, an insulating color ink which was prepared in accordance with the following insulating color resin composition 1 was applied onto the wiring electrode 8 to form an insulating color film 11.

[0113] The insulating color resi...

example 2

[0146] A solar battery module was prepared as in Example 1 except that a resin coating of the following composition was formed on the cell surface instead of the lamination film. The solar battery module was tested as in Example 1, finding that it had a certain effect of unifying tones and operated as a solar battery without problems.

6 Composition of resin coating Parts by weight OH-bearing fluoro-resin 20 (Lumiflon LF200F by Asahi Glass K.K., hydroxyl value 26 mg KOH / g) .gamma.-butyrolactone 40 isophorone 30 Anti-foaming agent (TSA-720 by 3 Toshiba Silicone K.K.) Leveling agent (KS-66 by Shin-Etsu 1 Silicone K.K.)

[0147] The Lumiflon resin was completely dissolved in a solvent mixture of .gamma.-butyrolactone and isophorone, and dispersed in a zirconia ball mill for 48 hours. The anti-foaming agent and leveling agent were then added to the dispersion, which was mixed for a further 2 hours. The following hot crosslinking reaction components were added.

7 Parts by weight Methylated mel...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle | aaaaa | aaaaa |

| Angle | aaaaa | aaaaa |

| Angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com