Process for synthesis of triisopropanolamine

A technology of triisopropanolamine and synthesis method, applied in chemical instruments and methods, preparation of organic compounds, preparation of amino hydroxy compounds, etc., can solve the problems of low product concentration, large investment in production equipment, complicated processes, etc. The process is simple, the dehydration energy consumption is reduced, and the investment cost is low.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

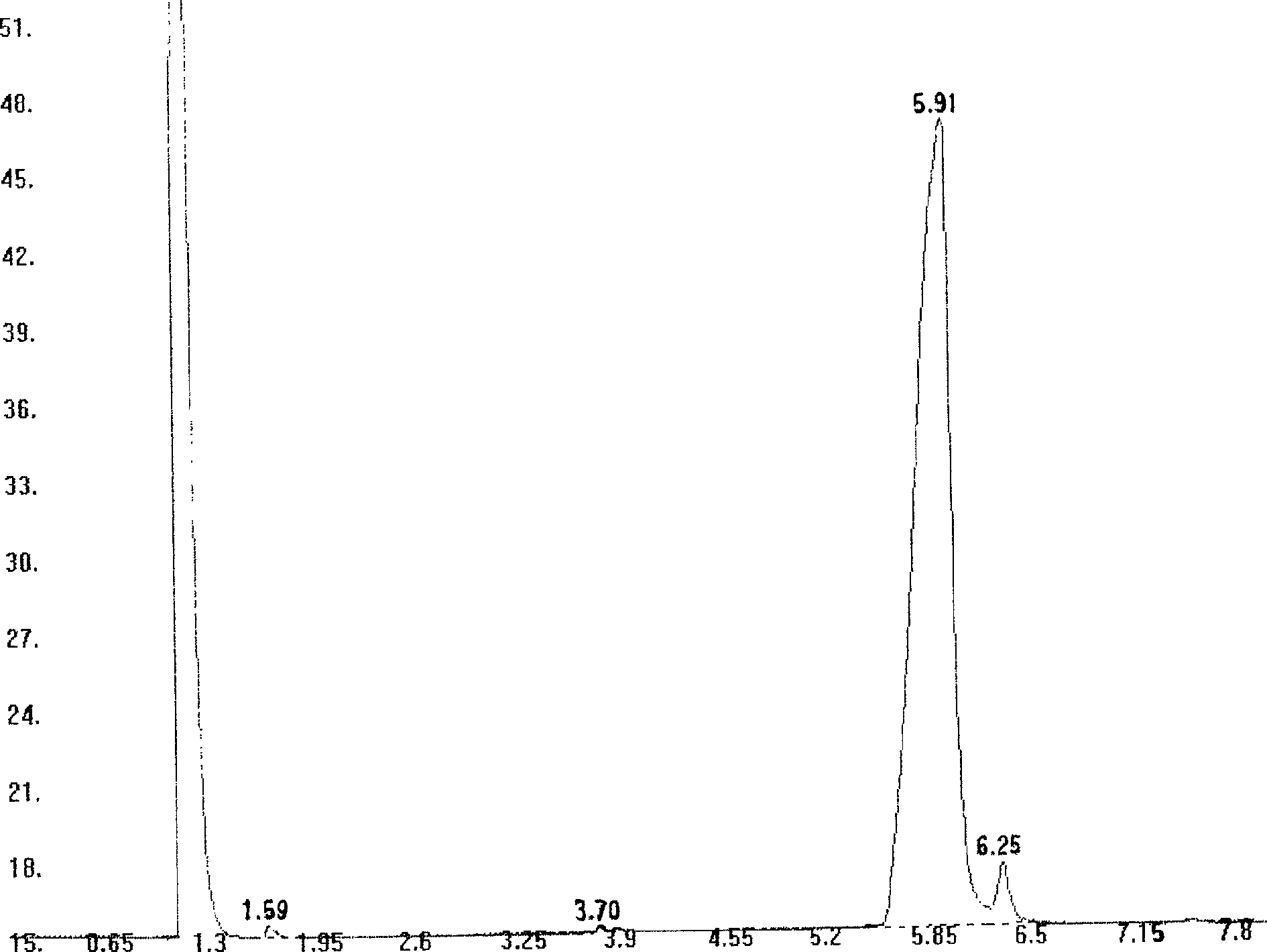

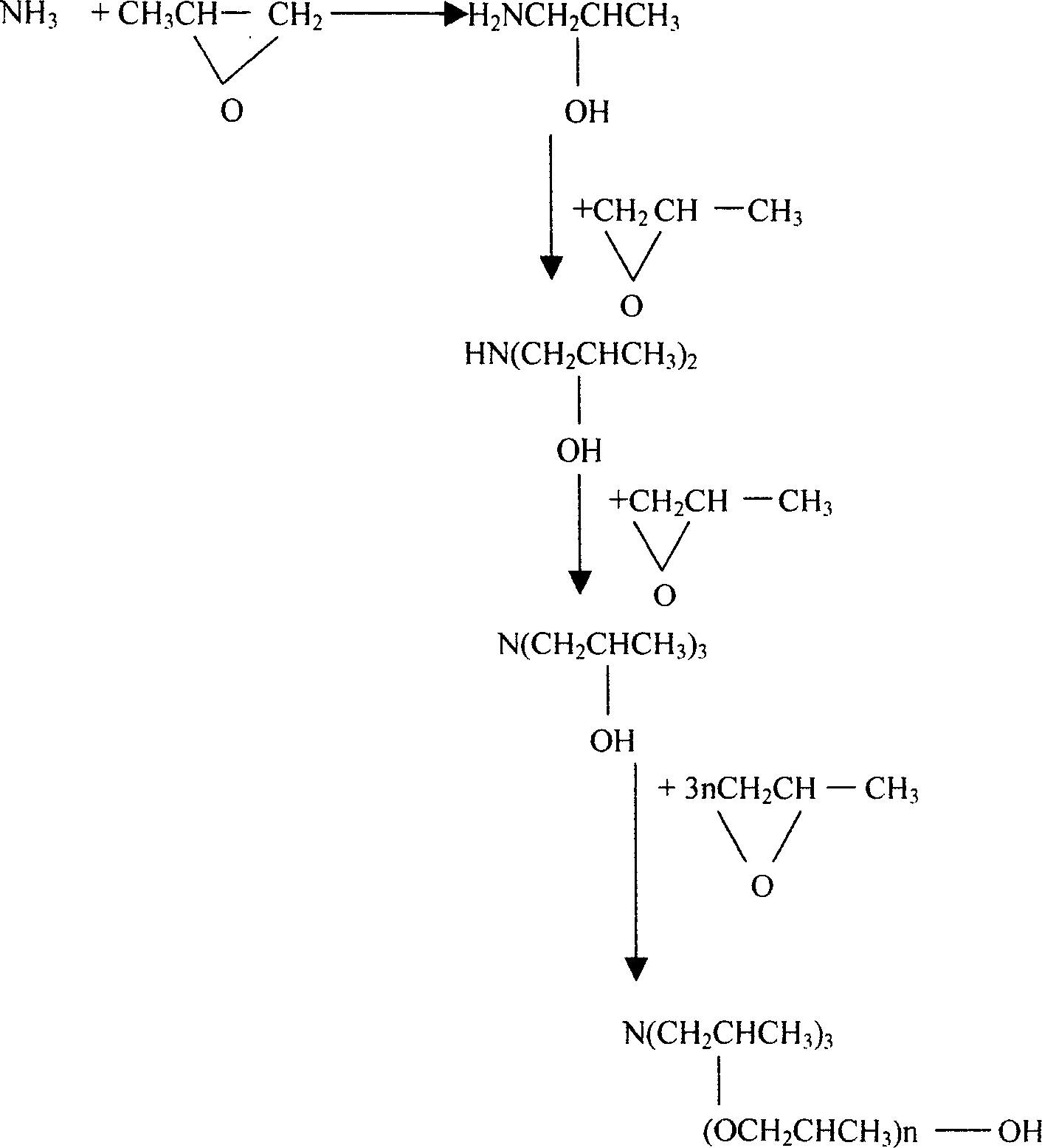

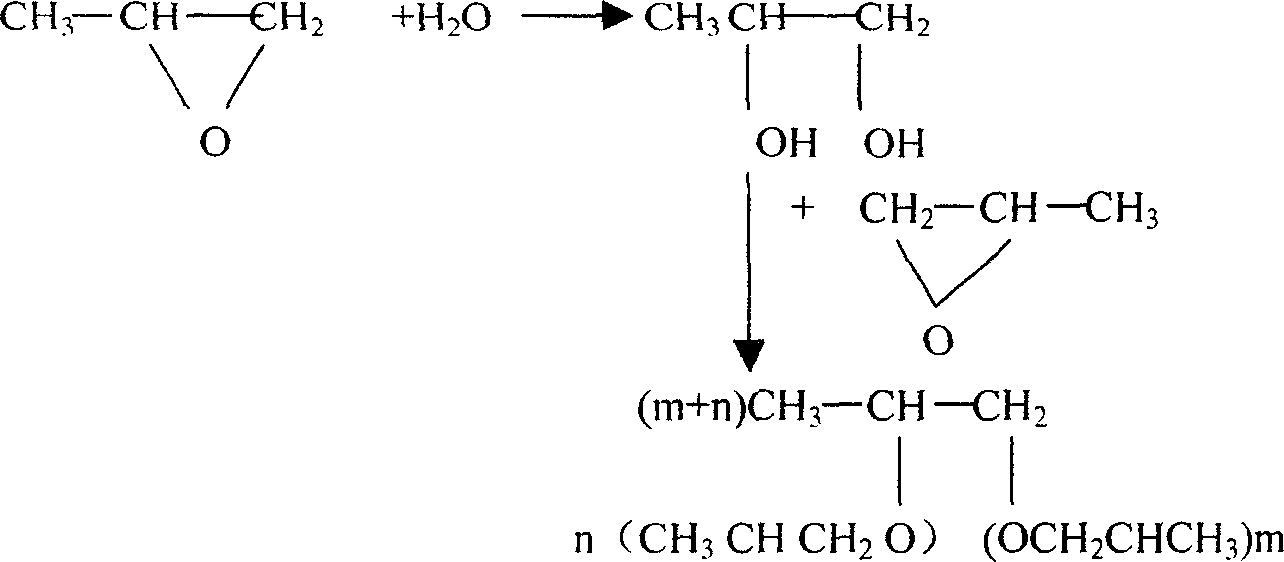

[0022] to 1M 3 The reactor was depressurized to -0.098Mpa, and the decompression was stopped, and 80kg of deionized water was added into the kettle, and 32kg of liquid ammonia was pumped into the reactor to make the ammonia form a supersaturated solution. Control the reaction temperature at 20-75°C, slowly add 330 kg of propylene oxide to the reactor at a feeding rate of 2-5 kg / min, and control the pressure of the reactor below 0.5 MPa. When adding propylene oxide, attention should be paid: the pressure of the canned pump should be controlled to be greater than the outlet pressure of the liquid ammonia storage tank and the pressure of the reactor to prevent the material from flowing backward. Pass into liquid ammonia 32kg for the second time, operation method and condition are the same as before; Add propylene oxide 330kg for the second time; Operation method is the same as before. After the addition of propylene oxide, heat preservation and aging for 1.0-3.0 hours, temperatu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com