Green and environment-friendly water-based antirust agent and preparation method thereof

A water-based anti-rust agent, green and environmentally friendly technology, applied in the production field of water-based anti-rust agents, can solve the problems of high cost, serious pollution, poor anti-rust effect, etc., achieve good environmental sanitation, reduce usage, and shorten the service life long effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

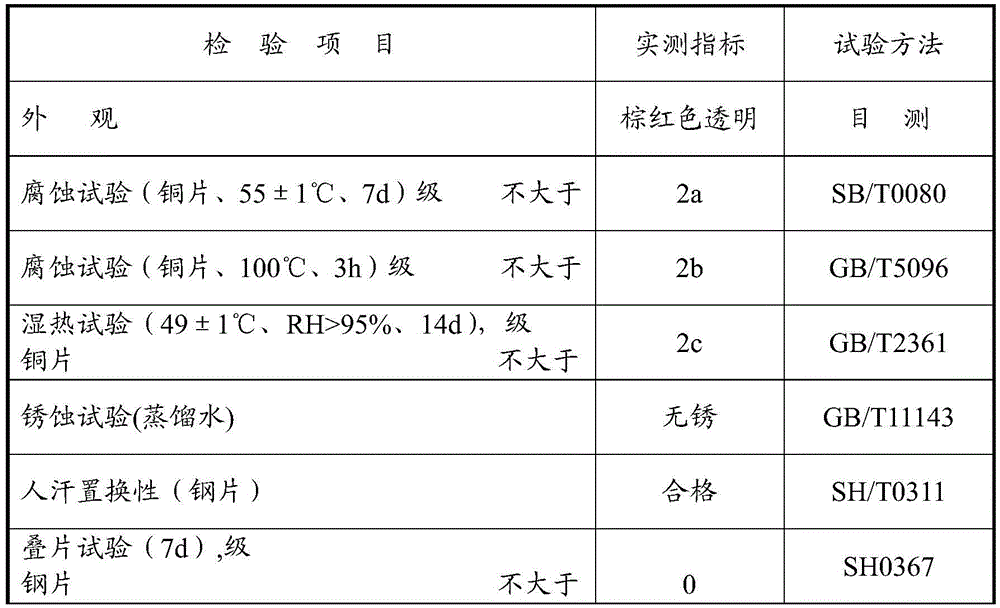

Image

Examples

preparation example Construction

[0023] The preparation method of the green and environment-friendly water-based antirust agent of the present invention, the raw materials include sebacic acid, lauric acid, triethanolamine, monoisopropanolamine, EDTA disodium salt, borax, bactericide, and benzotriazole components, Concrete reaction steps are as follows:

[0024] Step 1: Add sebacic acid, lauric acid, and triethanolamine into the esterification reactor at a mass ratio of 3:2:10, start stirring, heat the mixture until the temperature is 75-85°C and keep it warm, and react for about 1.5 hours Afterwards, the mixture reacts completely and turns into a light yellow to reddish brown transparent viscous liquid, that is, the antirust agent monomer; dibasic acid and triethanolamine account for 27%-38% of the total preparation content;

[0025] Step 2: Control the temperature of the antirust agent monomer described in step 1 at 75-80°C, add 75% of the total weight of the required water, and stir for 0.5h to dissolve th...

Embodiment 1

[0031] Embodiment 1 produces green environment-friendly type water-based antirust agent

[0032] Step A: Add 30kg of sebacic acid, 20kg of lauric acid, and 100kg of triethanolamine into the esterification reaction kettle in sequence, start stirring, heat the mixture until the temperature is 75-85°C and keep it warm. After about 1.5 hours of reaction, the mixture is completely reacted as Light yellow to reddish-brown transparent viscous liquid is the rust inhibitor monomer; dibasic acid and triethanolamine account for 35% of the total preparation content;

[0033] Step B: Control the temperature of the antirust agent monomer described in step A at 75-80°C, add 75% of the total weight of the required water, that is, 190.278kg, and stir for 0.5h, so that the antirust agent monomer is evenly dissolved in the water; Water is tap water, and the total amount accounts for 59.2% of the total preparation content;

[0034] Step C: Add 4.3 kg of monoisopropanolamine to the mixed solution...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com