Water-soluble cutting fluid and preparation method thereof

A cutting fluid and water-soluble technology, applied in the field of water-soluble cutting fluid and its preparation, can solve the problems of not having a great breakthrough, service life, and no use performance and effect of anti-embroidery, and achieve good extreme pressure lubricity. , high stability, the effect of expanding the application field

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

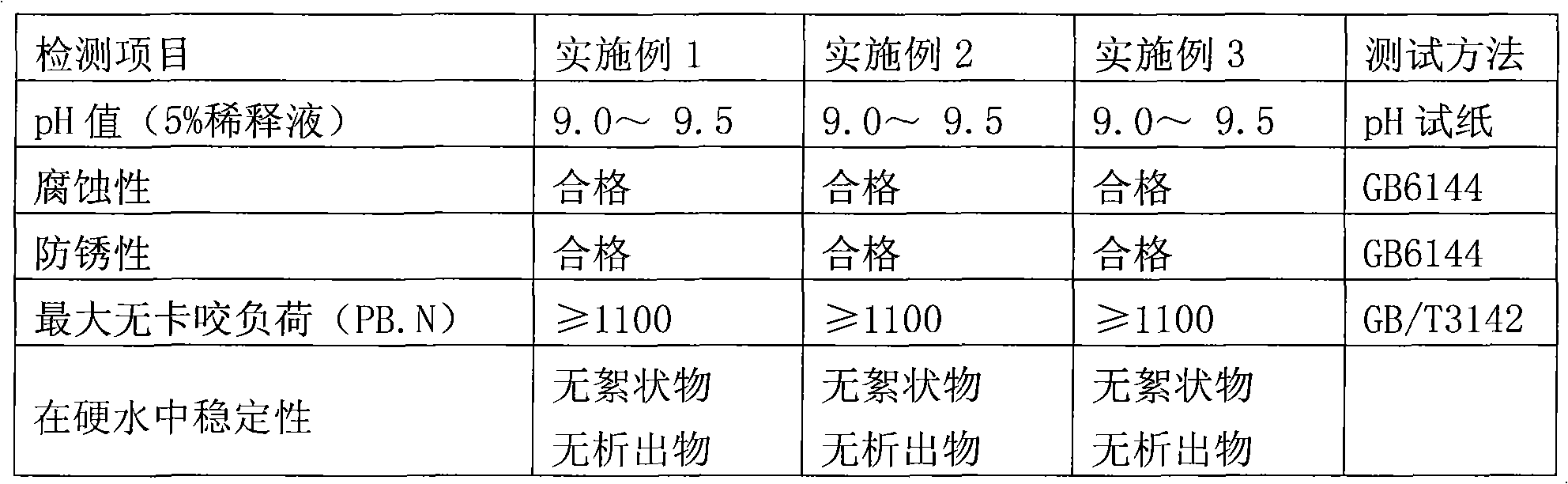

Embodiment 1

[0022] The water-soluble cutting fluid of this embodiment consists of the following components by weight percentage: 18% of oleic acid-2-ethylhexyl ester, 4% of 3,5,5-trimethylhexanoic acid, 4% of sebacic acid, Monoethanolamine 6%, triethanolamine 15%, diethylene glycol 7%, monoisopropanolamine 4%, polyethylene glycol 60016%, water 26%.

[0023] Mix 2-ethylhexyl oleate, 3,5,5-trimethylhexanoic acid, monoethanolamine and water accounting for 50% of the total water in the above weight ratio and react at a temperature of 60°C for 1 hour to obtain alcohol Amine synthetic grease mixture A; at the same time, sebacic acid, triethanolamine, monoisopropanolamine and water accounting for 50% of the total water were mixed together at a temperature of 80° C. for 1.5 hours to obtain alcohol amine synthetic grease mixture B; Then, the alcohol amine synthetic fat mixture A, the alcohol amine synthetic fat mixture B, diethylene glycol and polyethylene glycol 600 were stirred and mixed at a te...

Embodiment 2

[0025] The water-soluble cutting fluid of this embodiment consists of the following components by weight percentage: 20% of oleic acid-2-ethylhexyl ester, 5% of 3,5,5-trimethylhexanoic acid, 4% of sebacic acid, Monoethanolamine 6%, triethanolamine 15%, diethylene glycol 6%, monoisopropanolamine 5%, polyethylene glycol 600 15%, water 24%.

[0026] Mix 2-ethylhexyl oleate, 3,5,5-trimethylhexanoic acid, monoethanolamine and water accounting for 50% of the total water in the above weight ratio and react at a temperature of 65°C for 1 hour to obtain alcohol Amine synthetic fat mixture A; at the same time, the specified weight ratio of sebacic acid, triethanolamine, monoisopropanolamine and water accounting for 50% of the total water were mixed together and reacted at a temperature of 85°C for 2 hours to obtain alcohol amine synthetic fat mixture B ; Then the alcohol amine synthetic fat mixture A, the alcohol amine synthetic fat mixture B, diethylene glycol and polyethylene glycol 6...

Embodiment 3

[0028] The water-soluble cutting fluid of this embodiment consists of the following components by weight percentage: 21% oleic acid-2-ethylhexyl ester, 3,5,5-trimethylhexanoic acid 3%, sebacic acid 5%, Monoethanolamine 6%, triethanolamine 16%, diethylene glycol 6%, monoisopropanolamine 4%, polyethylene glycol 600 16%, water 23%.

[0029] Mix 2-ethylhexyl oleate, 3,5,5-trimethylhexanoic acid, monoethanolamine and water accounting for 50% of the total water in the above weight ratio and react at a temperature of 70°C for 1 hour to obtain alcohol Amine synthetic fat mixture A; at the same time, the specified weight ratio of sebacic acid, triethanolamine, monoisopropanolamine and water accounting for 50% of the total water were mixed together and reacted at a temperature of 90°C for 1.5 hours to obtain the alcohol amine synthetic fat mixture B ; Then the alcohol amine synthetic fat mixture A, the alcohol amine synthetic fat mixture B, diethylene glycol and polyethylene glycol 600 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com