Concrete surface sealing curing treatment enhancing agent

A concrete surface, sealing and curing technology, which is applied in the field of concrete surface sealing and curing treatment enhancers, can solve the problems of inability to prevent corrosion, concrete back to alkali, high price, etc., and achieve the effect of improved sealing and curing, dense concrete surface, and low alkali content.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

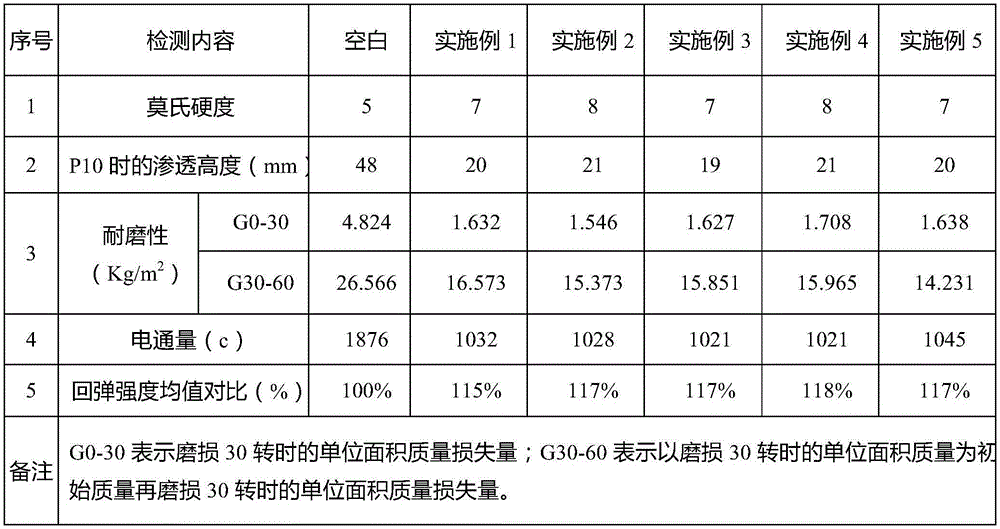

[0039] Example 1: A concrete surface sealing and curing treatment enhancer, which is prepared from the following parts by mass of raw materials through shear emulsification:

[0040] Penetrant 8%, of which: 4 parts of dodecyl alcohol polyoxyethylene ether phosphate (MOA2P) and 4 parts of dodecyl phosphate;

[0041] 21% accelerator, including: 3 parts of lithium silicate, 3 parts of lithium carbonate, 15 parts of sodium nitrite;

[0042] Complexing agent 5%, of which: 2.5 parts of triethanolamine, 2.5 parts of diethanol monoisopropanolamine;

[0043] Dispersant 5%, namely: 5 parts of melamine water reducing agent (solid content 30%);

[0044] Nano active agent 8%, namely: 8 parts of nano calcium carbonate;

[0045] Water 53%.

Embodiment 2

[0046] Example 2: A concrete surface sealing and curing treatment enhancer, which is prepared by shear emulsification with the following parts by mass of raw materials:

[0047] Penetrant 4%, including: 2 parts of MOA3P, 2 parts of dodecyl phosphate;

[0048] 35% of accelerator, including: 5 parts of lithium silicate, 5 parts of lithium carbonate, 25 parts of sodium nitrite;

[0049] Complexing agent 4%, of which: 2 parts of triethanolamine, 2 parts of diethanol monoisopropanolamine;

[0050] Dispersant 3%, of which: 3 parts of melamine water reducing agent (solid content 30%);

[0051] Nano active agent 6%, namely: 6 parts of nano calcium carbonate;

[0052] Water 47%.

Embodiment 3

[0053] Example 3: A concrete surface sealing and curing treatment enhancer, which is prepared by shear emulsification with the following parts by mass of raw materials:

[0054] Penetrant 3%, of which: 1.5 parts of dodecyl alcohol polyoxyethylene ether phosphate (MOA4P) and 1.5 parts of dodecyl phosphate;

[0055] 36% of accelerator, including: 6 parts of lithium silicate, 6 parts of lithium carbonate, 24 parts of sodium nitrite;

[0056] Complexing agent 3%, of which: 1.5 parts of triethanolamine, 1.5 parts of diethanol monoisopropanolamine;

[0057] Dispersant 2%, melamine water reducing agent (solid content 30%) 2 parts;

[0058] Nano active agent 4%, namely: 4 parts of nano calcium carbonate;

[0059] Water 52%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com