Corrosion inhibitor and method of inhibiting corrosion

A technology of corrosion inhibitors and surfactants, applied in the field of corrosion inhibitors, can solve the problems of thickening, insufficient long-term storage stability, and large discharge of washing waste liquid, and achieve the effect of reducing the discharge of waste liquid

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~5

[0043] Embodiment 1~5, comparative example 1, 2

[0044] [Preparation of Corrosion Inhibitors]

[0045] Add ingredients (A) to (C) or other ingredients into the production kettle according to the ratio shown in Table 1, heat and stir at 60-70°C to dissolve them evenly. Then, the amount of water shown in Table 1 was poured in, and the production kettle was kept at 45 to 50° C. and stirred for 3 to 4 hours. Then, it was slowly cooled to room temperature while stirring.

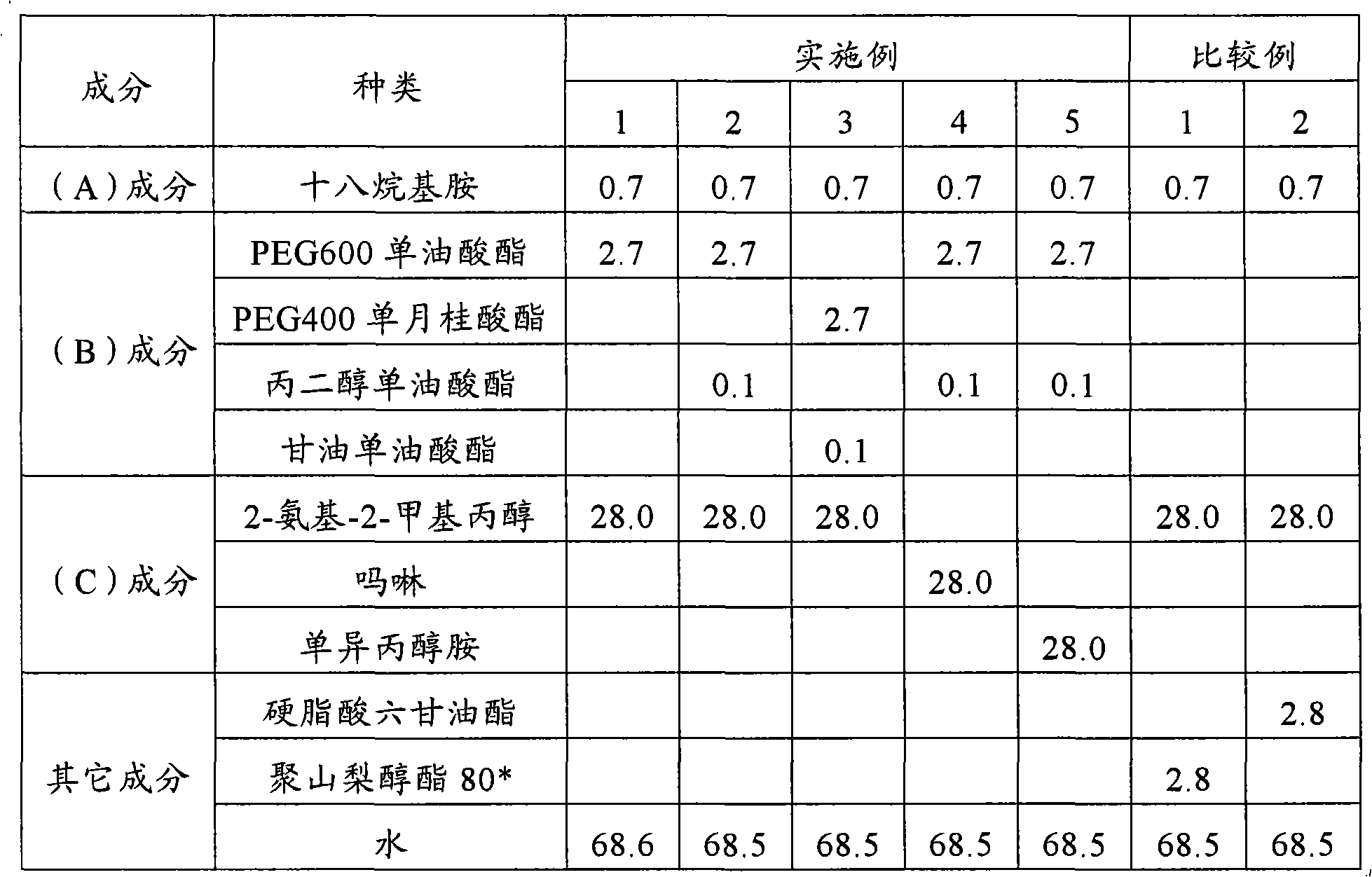

[0046] 【Table 1】

[0047] Proportion (weight)

[0048]

[0049] *Polyoxyethylene (20) sorbitan monooleate

[0050] [evaluation of storage stability]

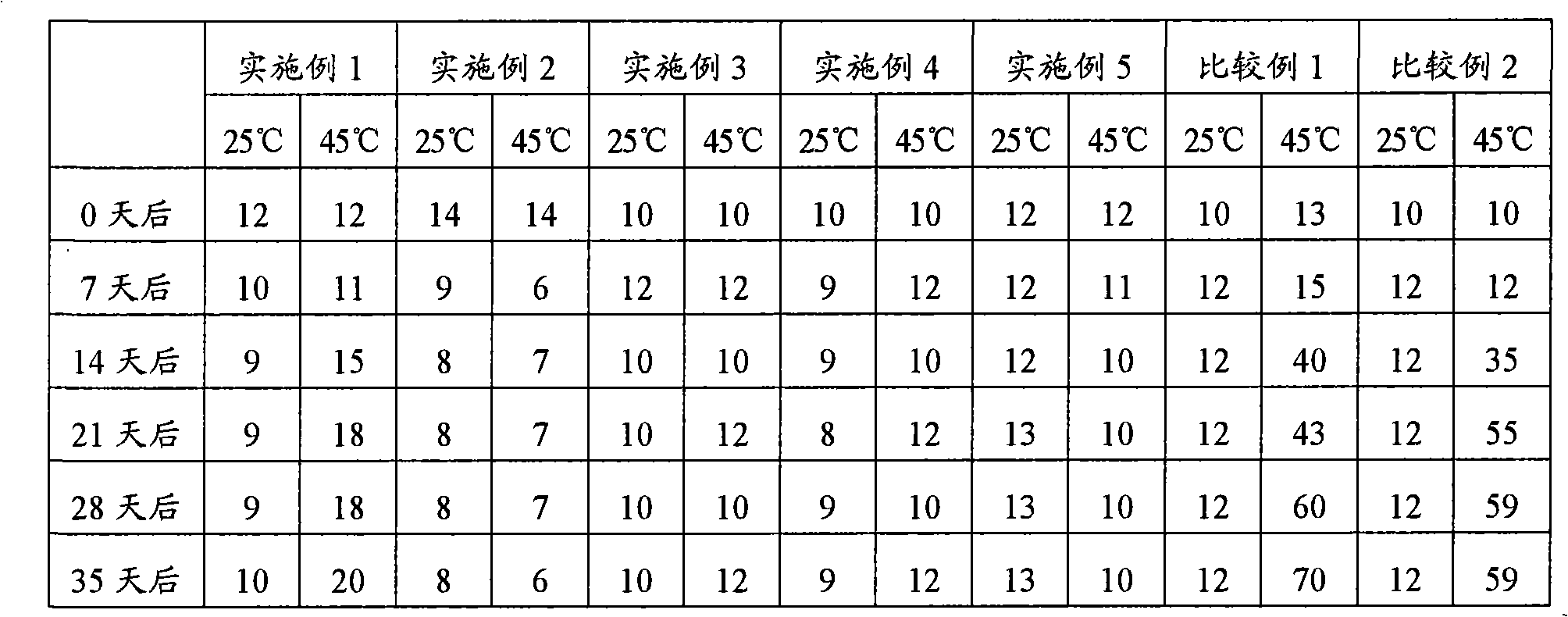

[0051] The medicaments prepared in each example were kept statically in a constant temperature tank at 25°C or 45°C, and were taken out in due course to investigate the change of viscosity with time. The results are shown in Table 2.

[0052] 【Table 2】

[0053] Storage stability evaluation results (viscosity: cps)

[0054]

[0055] As can be seen fro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com