Method for continuously producing high-efficiency concrete grinding aid

A cement grinding aid and high-efficiency technology, which is applied in the field of continuous preparation of high-efficiency cement grinding aid and the preparation of high-efficiency cement grinding aid, can solve the problems of time-consuming and labor-intensive, high production cost, adverse environmental impact, etc., and reduce production costs. , the effect of reducing production energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

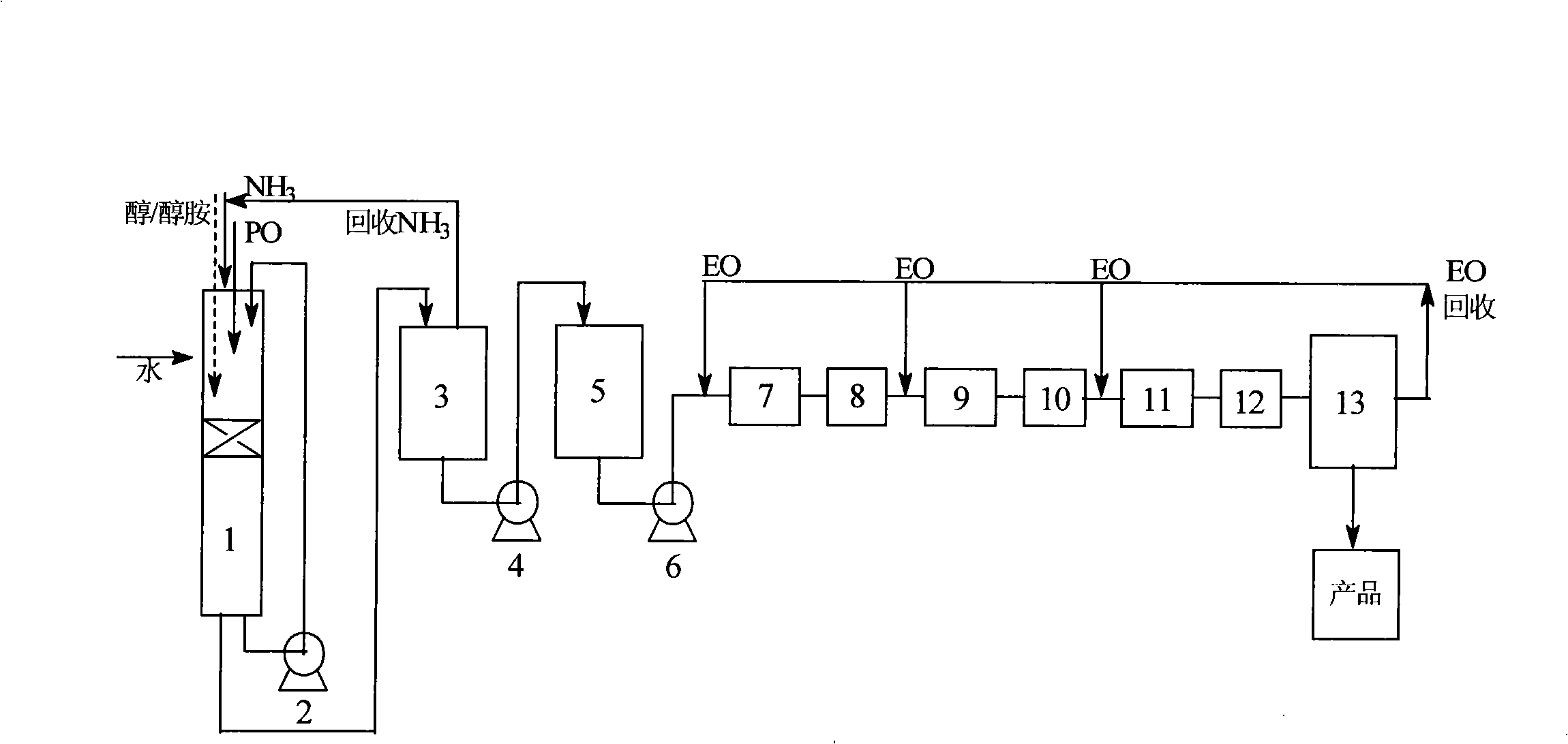

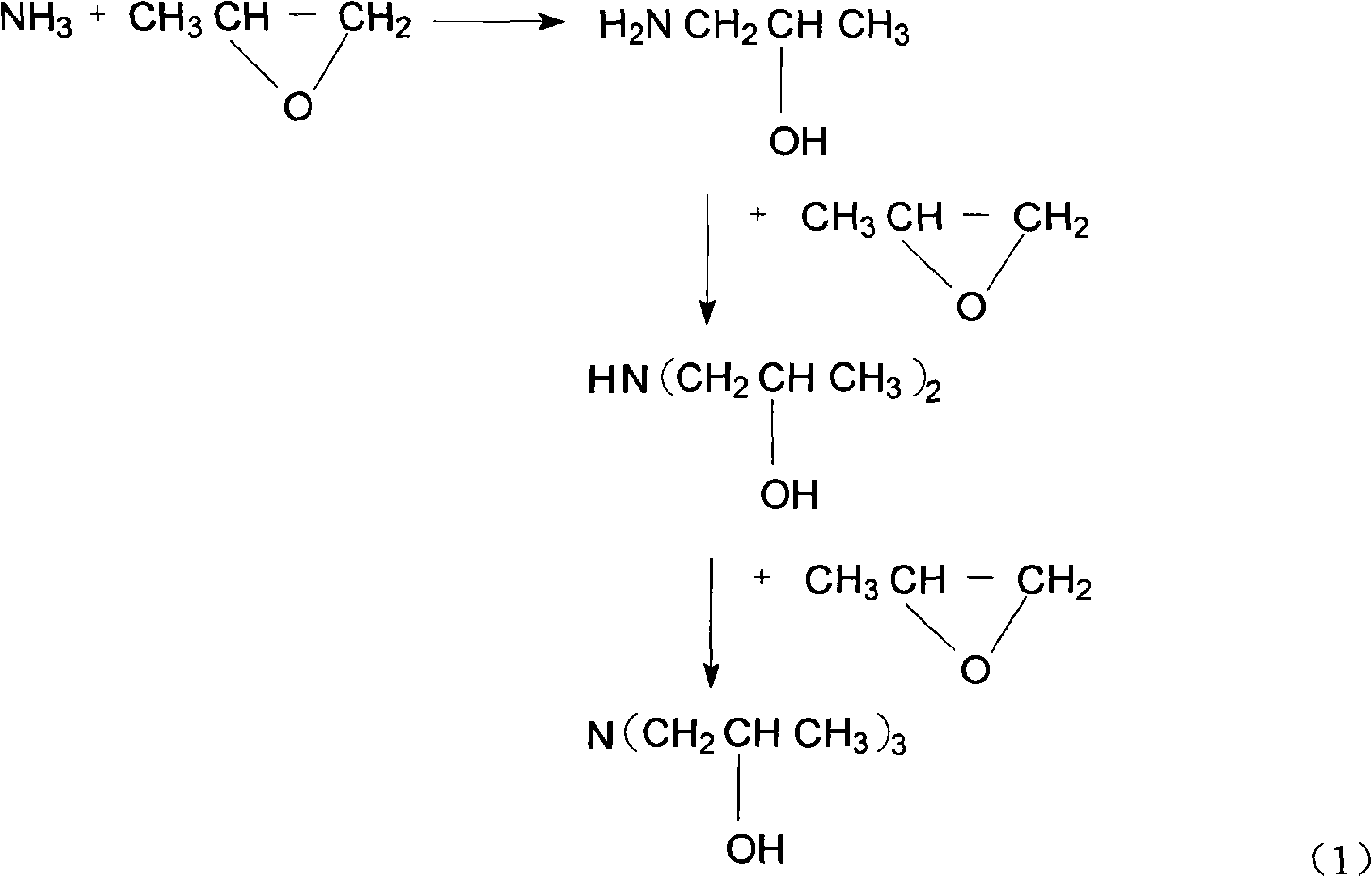

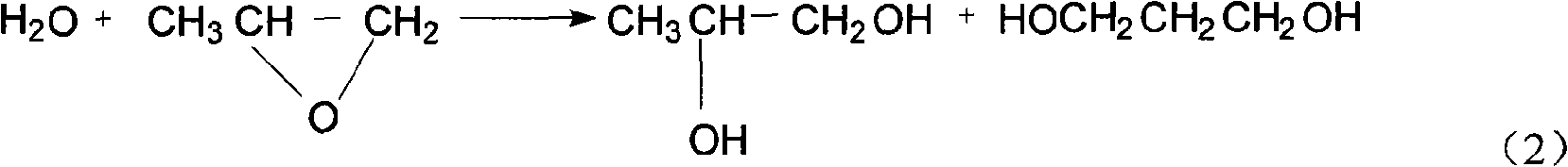

[0039] Add 1300kg of DEIPA to the 5000L continuous reactor 1, raise the temperature and turn on the external circulation pump 2, when the liquid phase temperature reaches 75°C, continuously spray 14kg / min water flow and 6kg / min ammonia flow from the top of the continuous reactor 1 And 4kg / min PO flow, control reaction pressure 1.8~2.5MPa, reaction temperature 65~90℃, residence time 1.5 hours. Keep the liquid level of the stream in the continuous reactor 1 at 2200-2300L, part of the stream is continuously sent to the flash tower 3, the tower pressure is kept between 0.4-0.8MPa, the temperature is 70-100°C, and the deamination is carried out. Ammonia content 2.83% in the stream, this stream flows through tundish 5, sampling detects, draws that the content of MIPA, DIPA is respectively 45.6% and 39.4%. The 3.6kg / min EO stream is divided into three sections according to the ratio of 40%, 35%, and 25%, and is continuously passed into static mixers 7, 9 and 11 at the same time as th...

Embodiment 2

[0041] Add 800kg DEIPA and 500kg EDIPA to the 5000L continuous reactor 1, heat up and open the external circulation pump 2, when the liquid phase temperature reaches 81°C, continuously spray 13kg / min water flow, 7kg / min ammonia from the top of the continuous reactor flow and 4kg / min PO flow, the reaction pressure is controlled to 1.7-2.3MPa, the reaction temperature is 65-100°C, and the residence time is 1.5 hours. Keep the liquid level of the stream in the continuous reactor 1 at 2000-2400L, part of the stream is continuously sent to the flash tower 3, the tower pressure is kept between 0.5-0.8MPa, the temperature is 80-110°C, deamination is carried out, and the deamination is analyzed The ammonia content in the stream after is 2.58%. This stream flows through the tundish 5 and is sampled for detection. The contents of MIPA and DIPA are 46.6% and 38.9% respectively. The 3.9kg / min EO stream is divided into three sections according to the ratio of 30%, 30%, and 40%, and is cont...

Embodiment 3

[0043] Add 1300kg of EDIPA to the 5000L continuous reactor 1, raise the temperature and turn on the external circulation pump 2, when the liquid phase temperature reaches 85°C, continuously spray 11.5kg / min water stream and 8.5kg / min ammonia from the top of the continuous reactor Flow and 4kg / minPO flow, control reaction pressure 1.7 ~ 2.3MPa, reaction temperature 75 ~ 105 ℃, residence time 2.2 hours. Keep the liquid level of the stream in the continuous reactor 1 at 2000-2300L, part of the stream is continuously sent to the flash tower 3, the tower pressure is kept between 0.6-0.9MPa, the temperature is 85-105°C, deamination is carried out, and the deamination is analyzed After the ammonia content in the stream is 3.05%, this stream flows through the tundish 5, and sampling is detected, and the content of MIPA and DIPA is 48.5% and 37.5% respectively. Divide the 4.5kg / min EO stream into three sections according to 40%, 30%, and 30%, and feed it into static mixers 7, 9 and 11 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com