Coating agent for water-based drilling fluid

A technology of water-based drilling fluid and coating agent, which is applied in the directions of drilling compositions, chemical instruments and methods, etc., can solve problems such as the inability to meet the requirements of on-site construction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

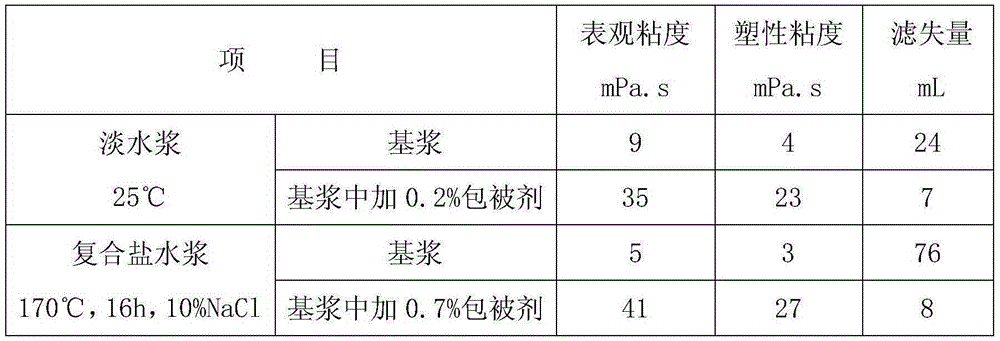

Examples

Embodiment 1

[0014] Embodiment 1 prepares coating agent for water-based drilling fluid

[0015] The preparation method is as follows:

[0016] At room temperature, turn on the stirring tank to stir, pour in 1000kg of liquid polyacrylamide, 200kg of AMPS and 180kg of N-methylpyrrolidone, stir well and then slowly add 80kg of soda ash, the speed is controlled within 30min; Heat up and stir, and control the temperature at 30-35°C; visually observe that all the materials are dissolved, stir the dissolved materials at a constant temperature, turn on the cooling water to cool down, control the temperature between 20-25°C, and stir for 30 minutes; pass the stirred materials through the air Press the compressor into the polymerization kettle, fill with nitrogen for 10 minutes, add 2 kg of sodium bisulfite, continue filling with nitrogen for 10 minutes, and add 2 kg of hydrogen peroxide. After filling nitrogen for 10 minutes, close the nitrogen cylinder, close the exhaust valve and wait for polyme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com