Patents

Literature

40results about How to "Avoid manufacturing errors" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

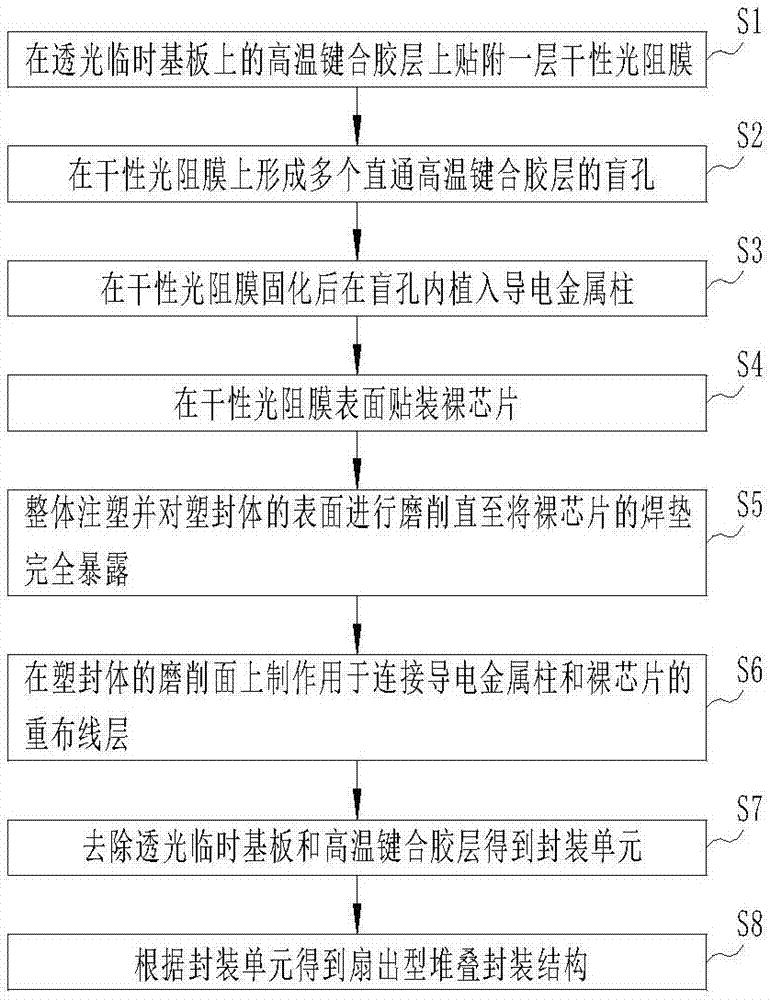

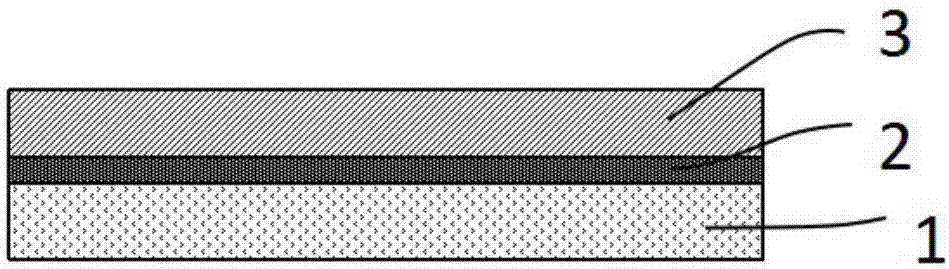

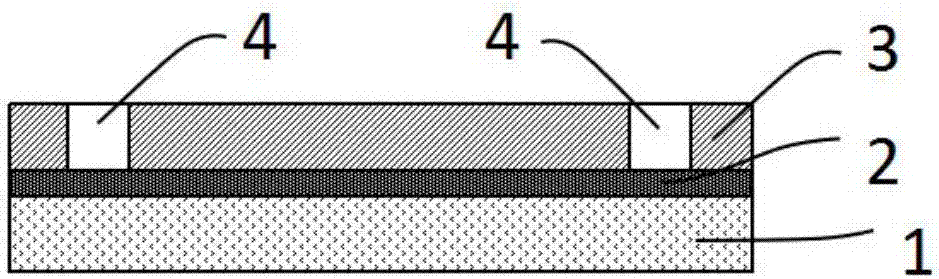

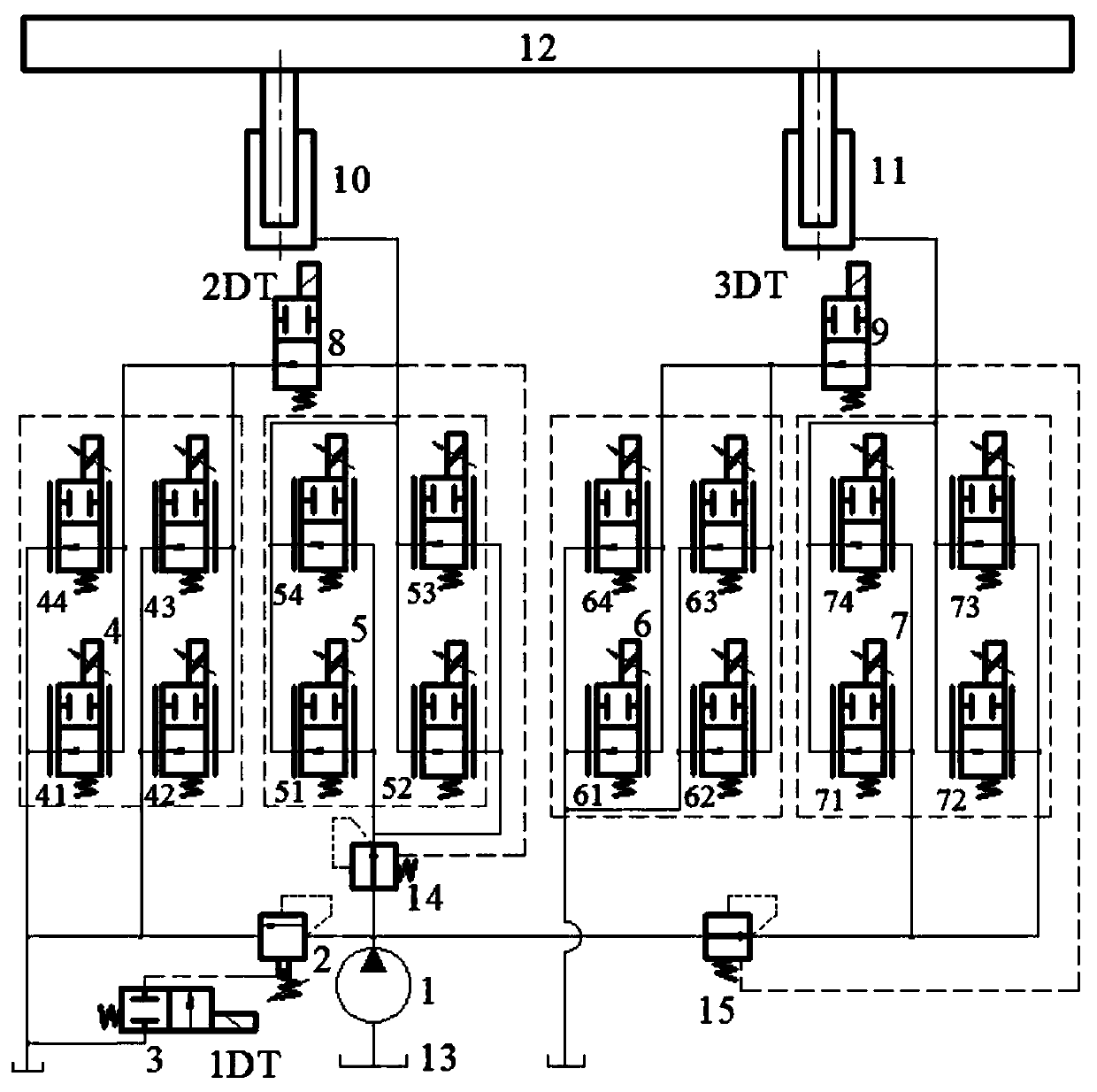

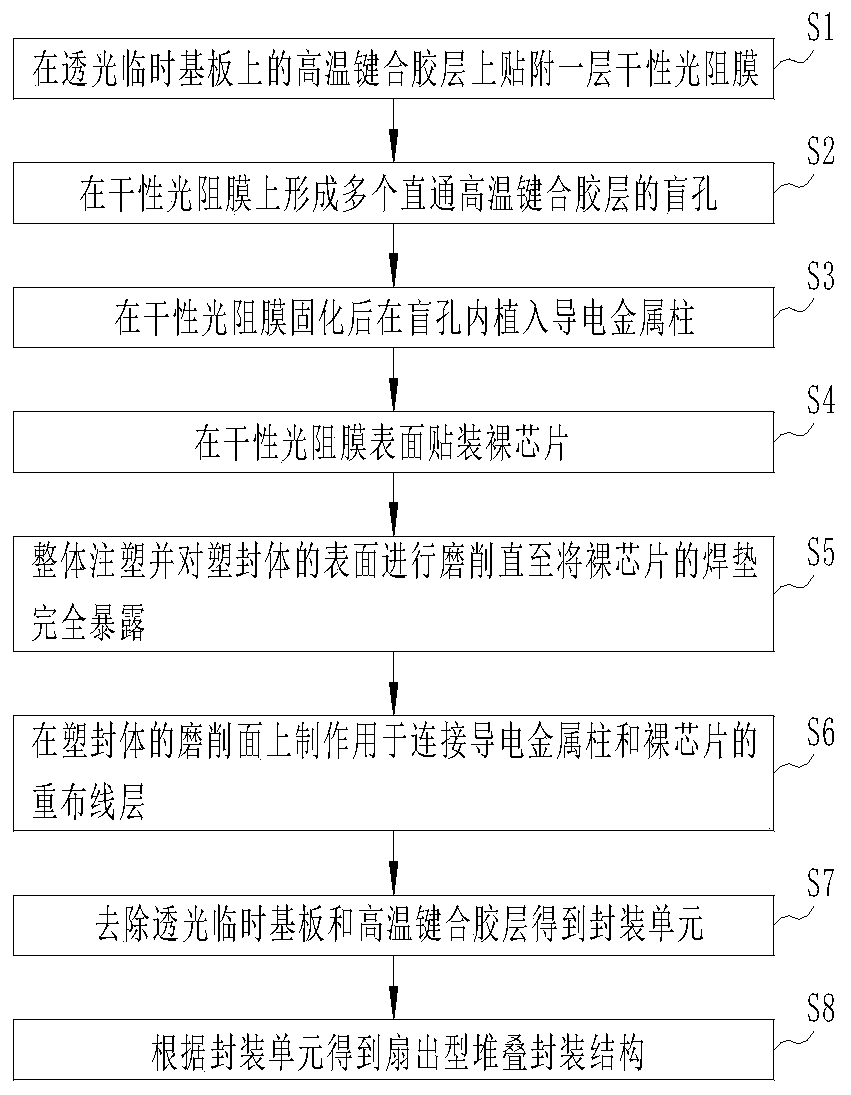

Wafer-level fan-out type stack package process method

ActiveCN107481945AReduce thicknessSimple processSolid-state devicesSemiconductor/solid-state device manufacturingManufacturing technologyInjection moulding

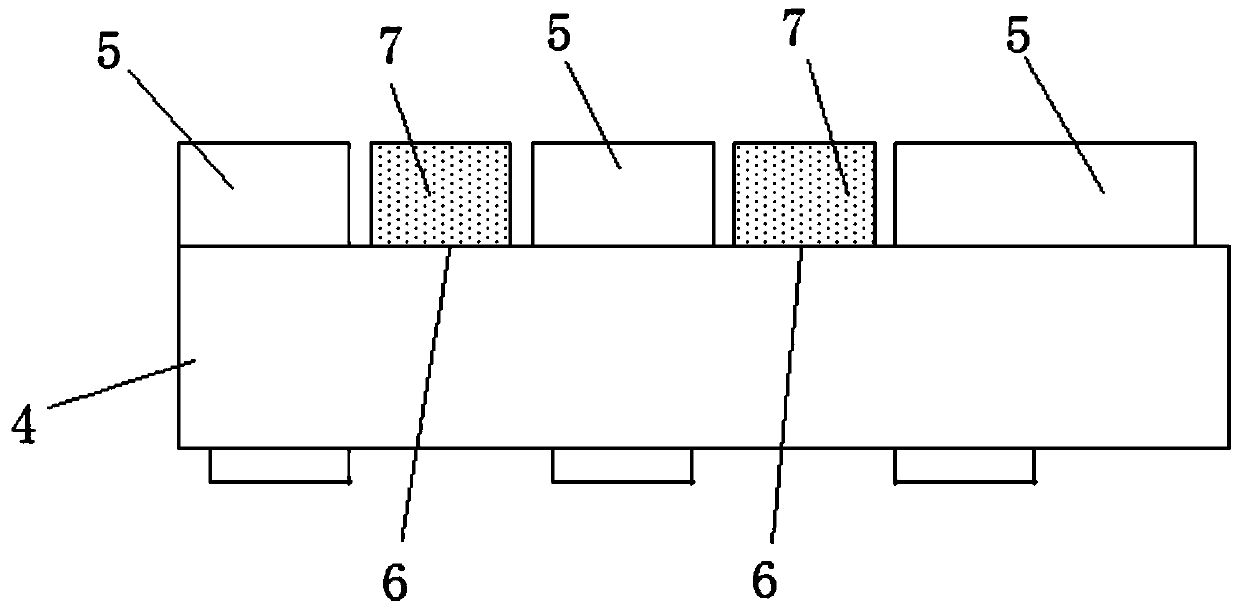

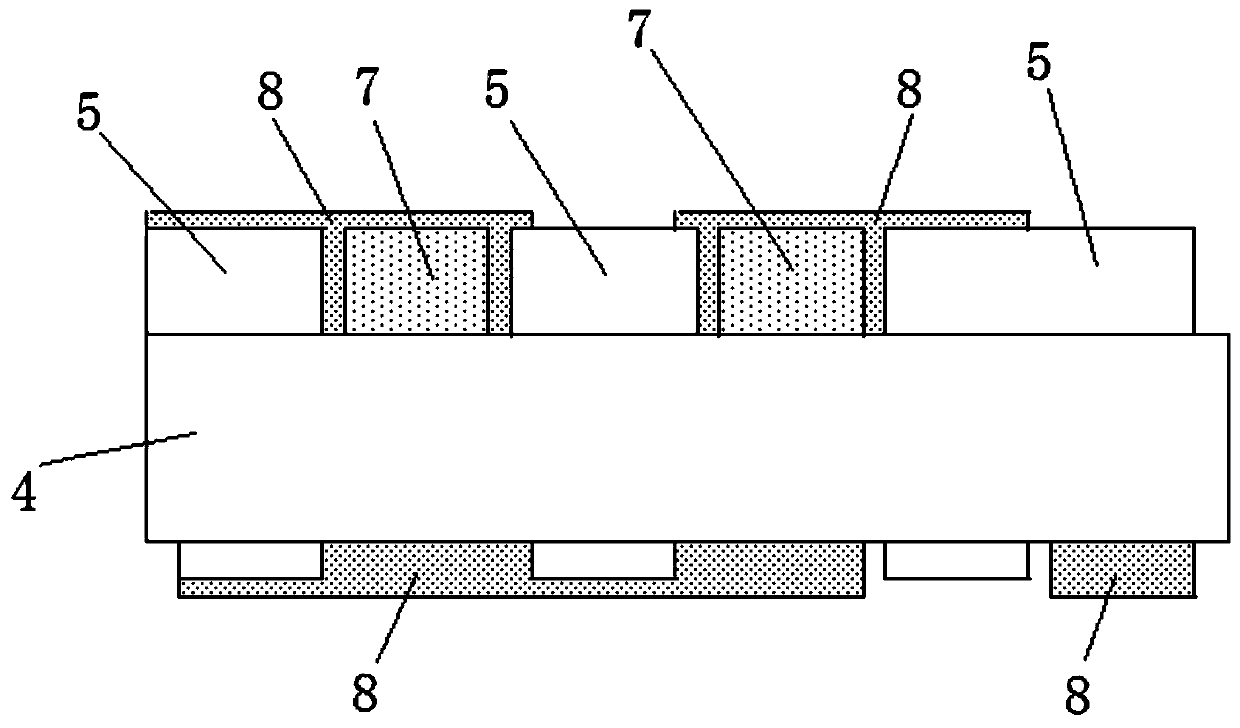

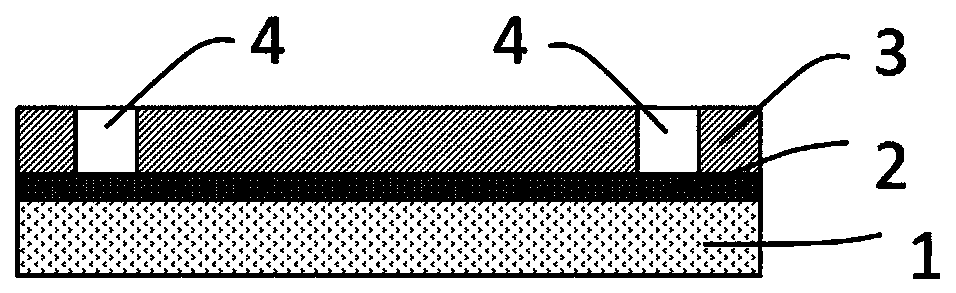

The invention discloses a wafer-level fan-out type stack package process method, and the method comprises the following steps: pasting a dry photoresistive membrane on a high-temperature bonding glue layer on a light-transmitting temporary substrate; forming a plurality of blind holes, which are directly communicated with the high-temperature bonding glue layer, on the dry photoresistive membrane; implanting conductive metal poles in the blind holes after the dry photoresistive membrane is solidified; pasting an unpacked chip on the surface of the dry photoresistive membrane; carrying out the integrated injection moulding, and carrying out the grinding of the surface of a plastic packaged body till the bonding pad of the unpacked chip is completely exposed; manufacturing a rewiring layer, used for connecting the conductive metal poles and the unpacked chip, on the grinding surface of the plastic packaged body, wherein the rewiring layer is provided with miniature salient points obtained through reballing and reflow soldering; removing the light-transmitting temporary substrate and the high-temperature bonding glue layer, and obtaining a package unit; and obtaining a fan-out stacked package structure according to the package unit. The method simplifies the manufacturing technology of a fan-out type stack package, and reduces the manufacturing cost of the stack package.

Owner:NAT CENT FOR ADVANCED PACKAGING

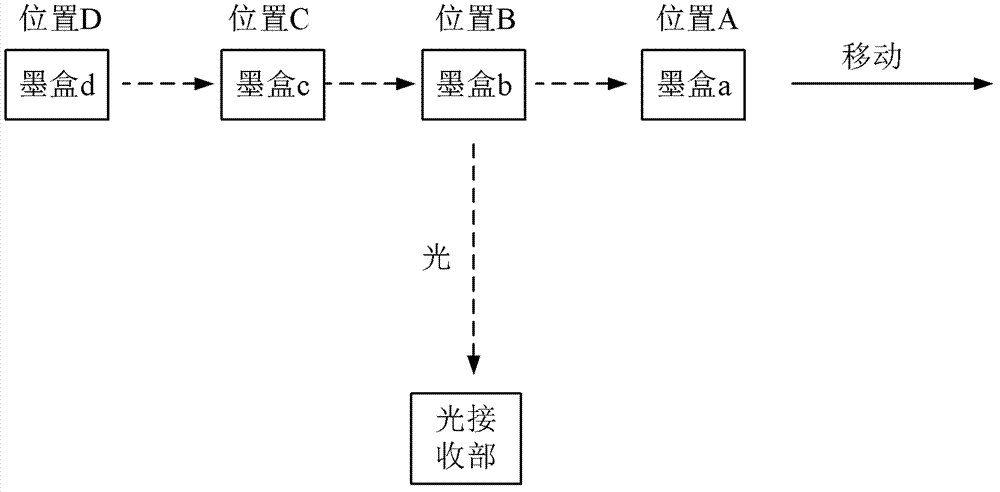

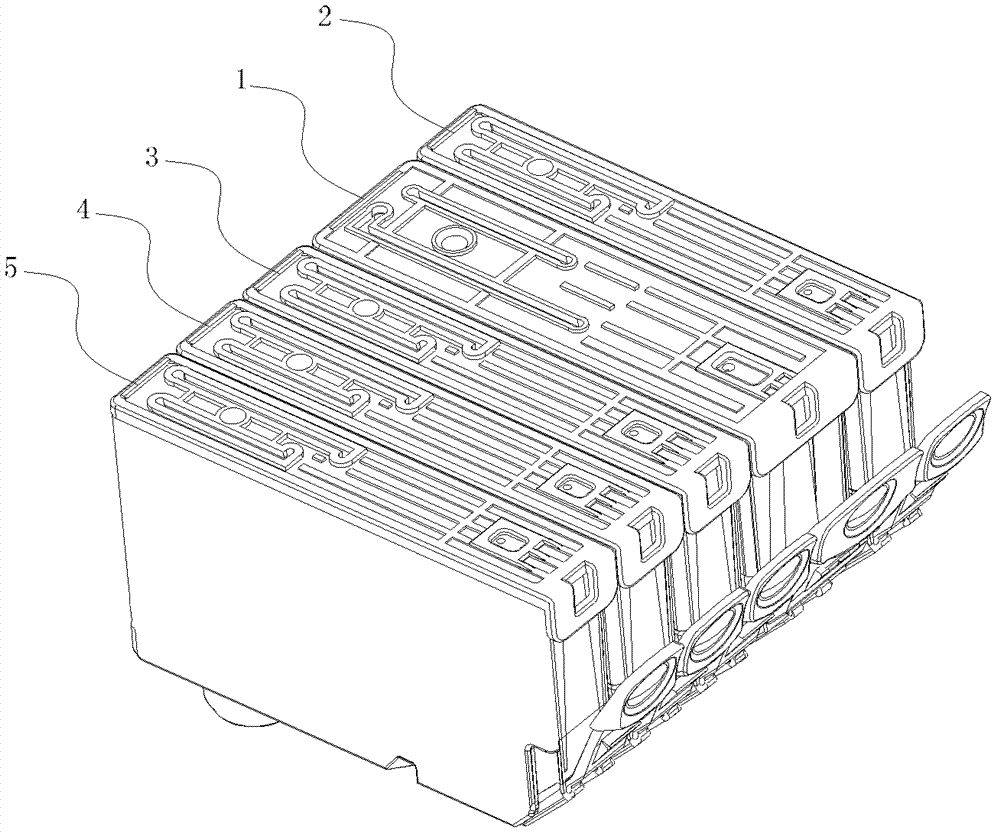

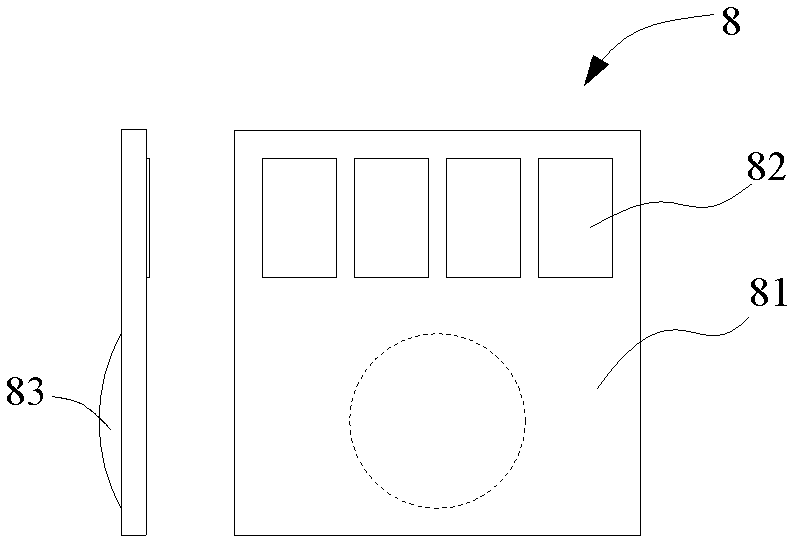

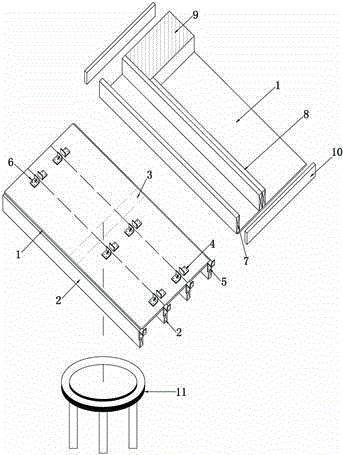

Inkjet cartridge group and method for detecting installed inkjet cartridge group

ActiveCN102950901AGuarantee the stability of installation detectionAvoid manufacturing errorsPrintingOptical receiversElectricity

The invention aims to provide an inkjet cartridge group and a method for detecting an installed inkjet cartridge group. The inkjet cartridge group is detachably installed on an inkjet printer and comprises a plurality of inkjet cartridges; the inkjet printer is communicated with the inkjet cartridges through equipment electric contacts which are arranged, and an optical receiver is arranged on the inkjet printer; a container electric contact, an information-storing device, a light-emitting part and a control part are arranged on each inkjet cartridge; and each control part controls the light of the light-emitting part when receiving the information which is sent out from the inkjet printer to control the light of any light-emitting part. According to the method for detecting the installed inkjet cartridge group, when a certain inkjet cartridge is detected, all the light-emitting parts send out lights. After the inkjet cartridge group and the method for detecting the installed inkjet cartridge group, the detection stability of the installed inkjet cartridges of the printer can be ensured completely, so that the phenomenon that installed inkjet cartridge detection error is caused by the manufacturing error of the light-emitting parts is avoided.

Owner:ZHUHAI NINESTAR MANAGEMENT CO LTD

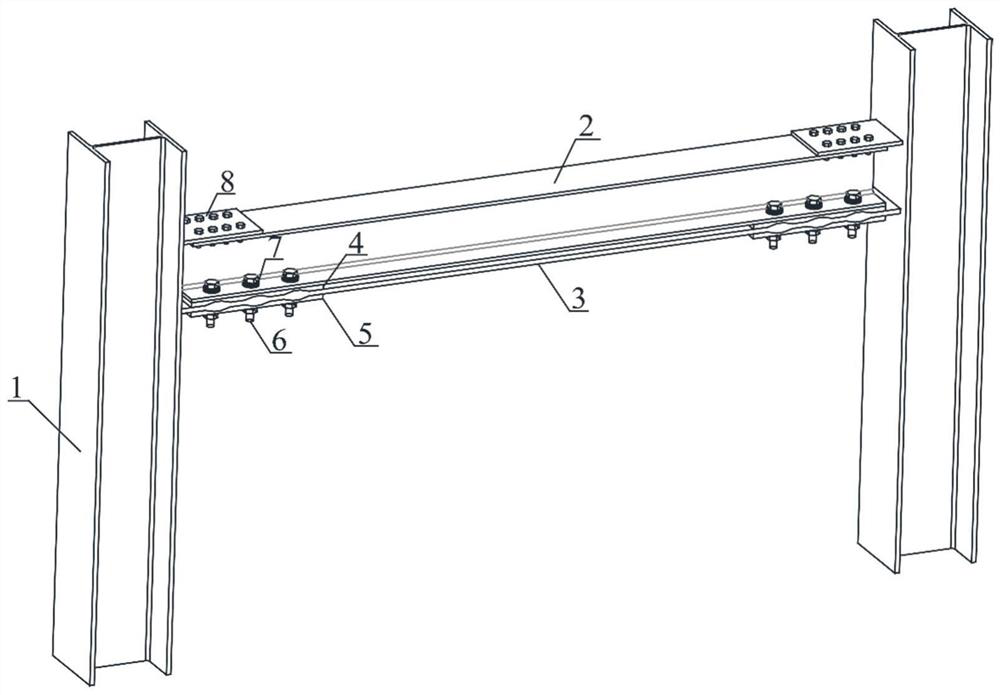

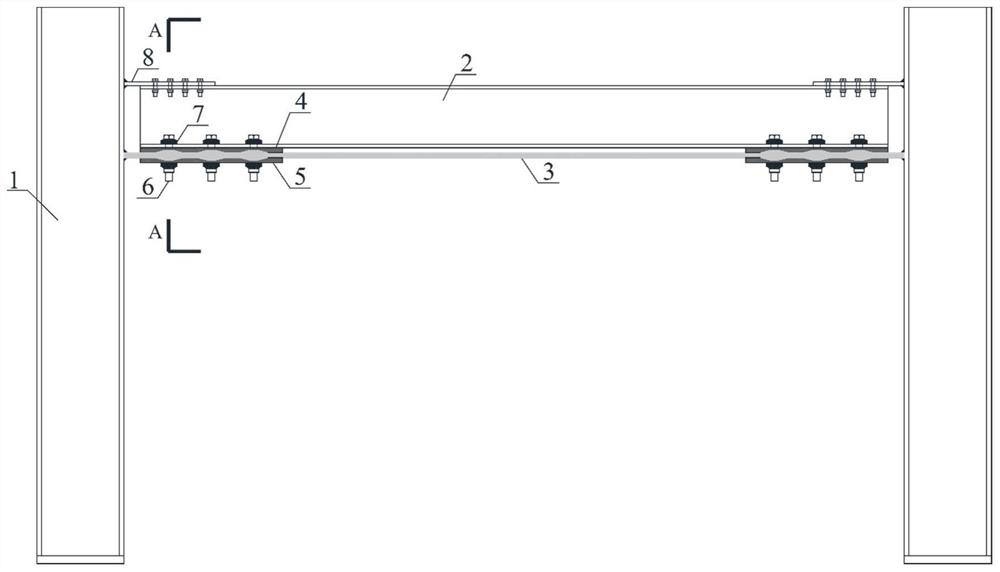

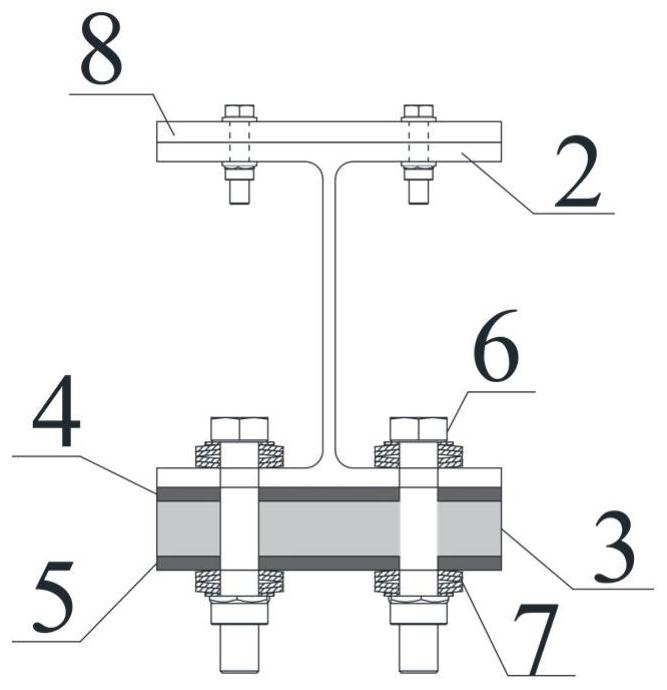

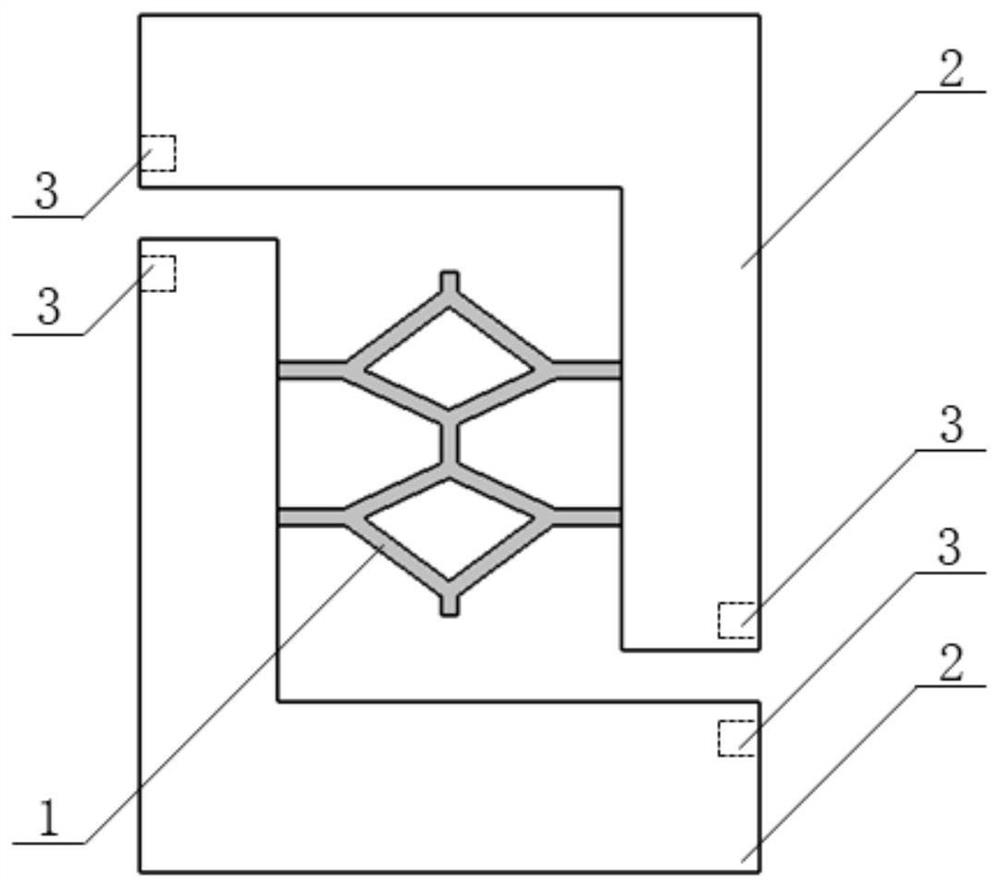

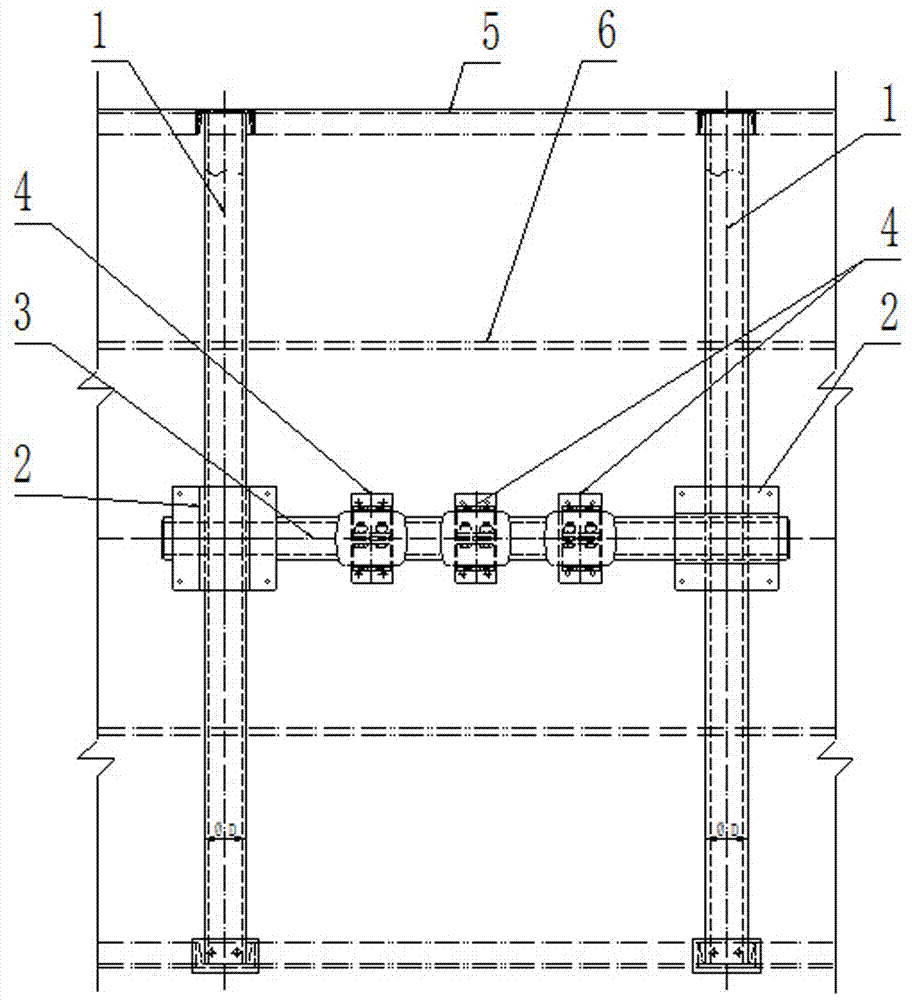

Steel frame with friction energy dissipation self reset device in beam

InactiveCN111608457AReduce economic costsConvenience needsProtective buildings/sheltersShock proofingSteel frameFlange

The invention discloses a steel frame with a friction energy dissipation self reset device in a beam. The steel frame includes at least one structural unit, each structural unit includes a frame column, an I-shaped steel beam, a full-length steel plate, an upper base plate, a lower base plate, a high-strength bolt and a butterfly gasket; the two ends of the I-shaped steel beam are connected with the frame column through flange plates, the two ends of the full-length steel plate are respectively connected with the frame column in a welded mode, the upper base plate is welded on the outer side of the I-shaped steel beam, the lower base plate is located on the lower side of the full-length steel plate, the high-strength bolt is used for connecting the I-shaped steel beam, the full-length steel plate, the upper base plate, with the lower base plate as a whole, the two sides of connection faces are correspondingly provided with slopes, and the butterfly gasket sleeves the high-strength bolt. The steel frame with the friction energy dissipation self reset device in the beam can be applied in steel frames, so the structure can realize the reset energy dissipation capacity under strong earthquake, and the economic loss after the earthquake is effectively reduced.

Owner:CHONGQING UNIV

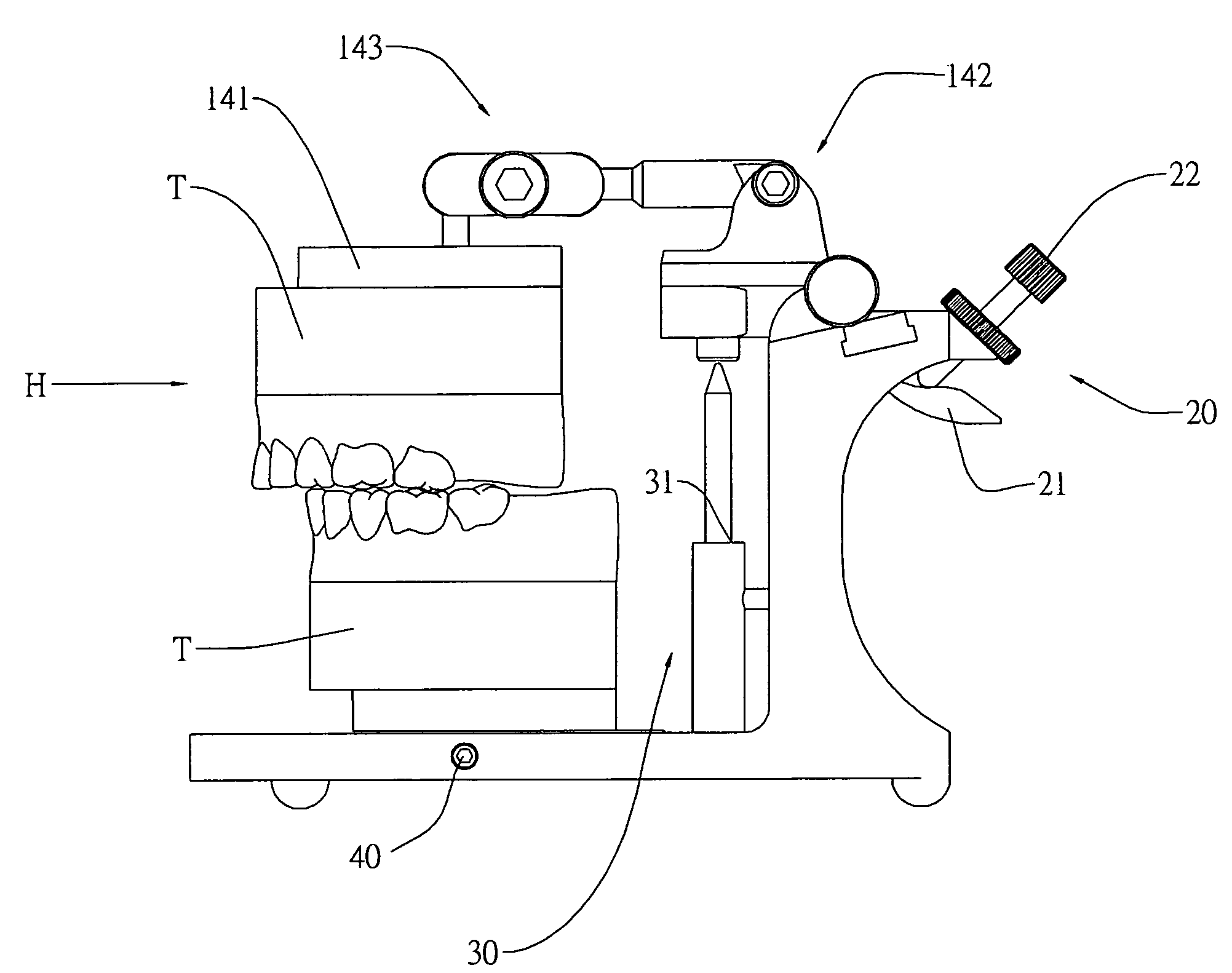

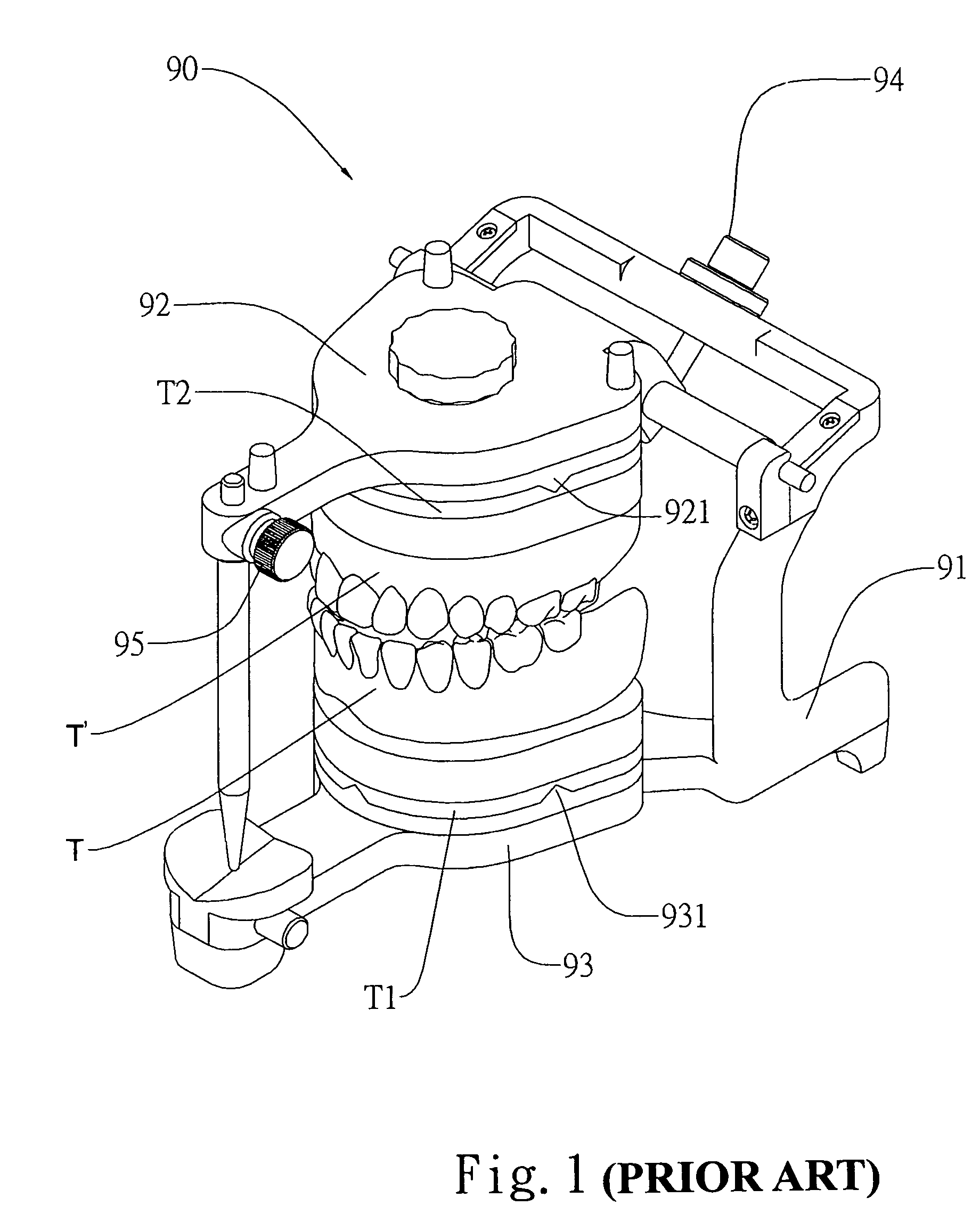

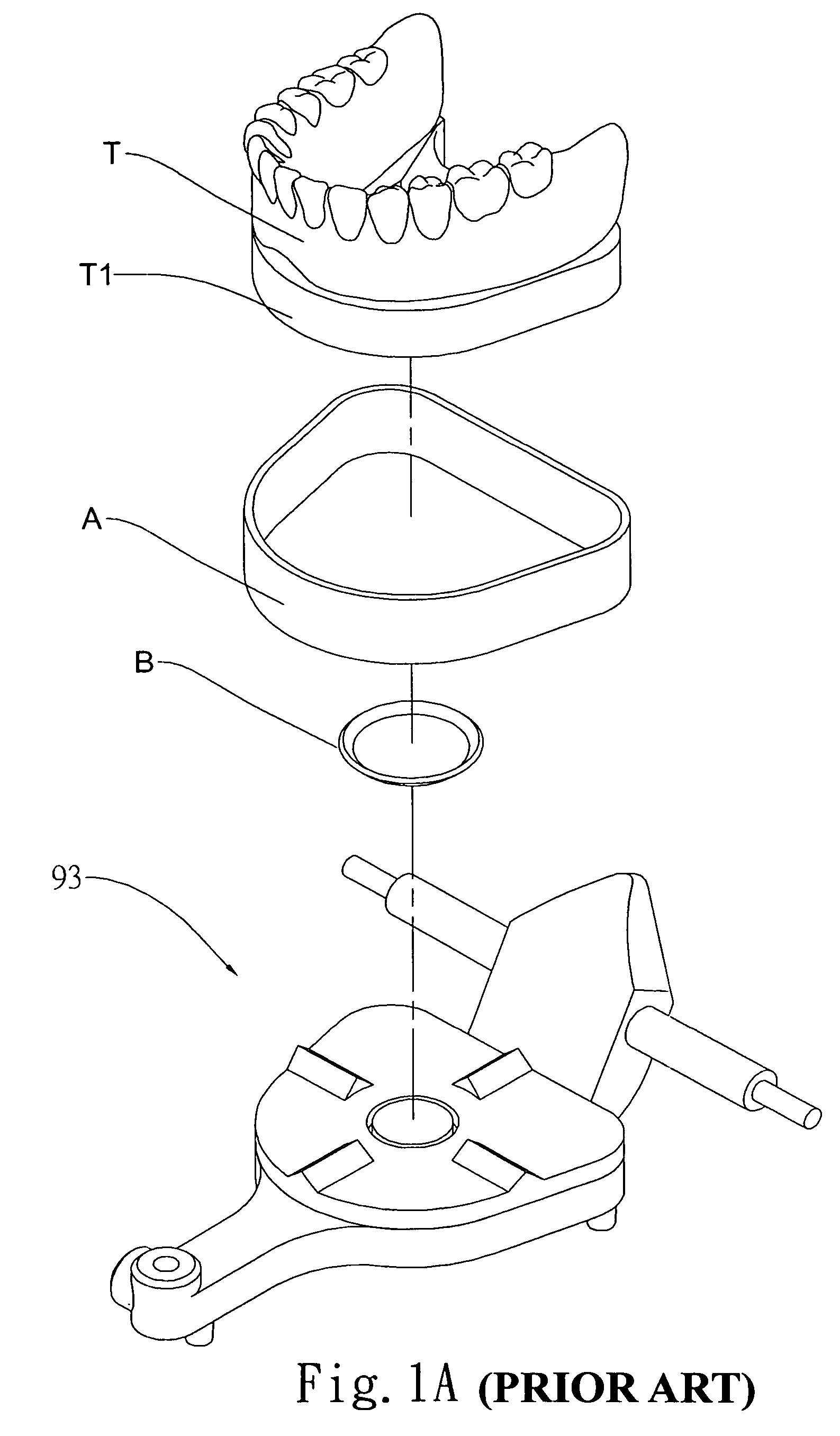

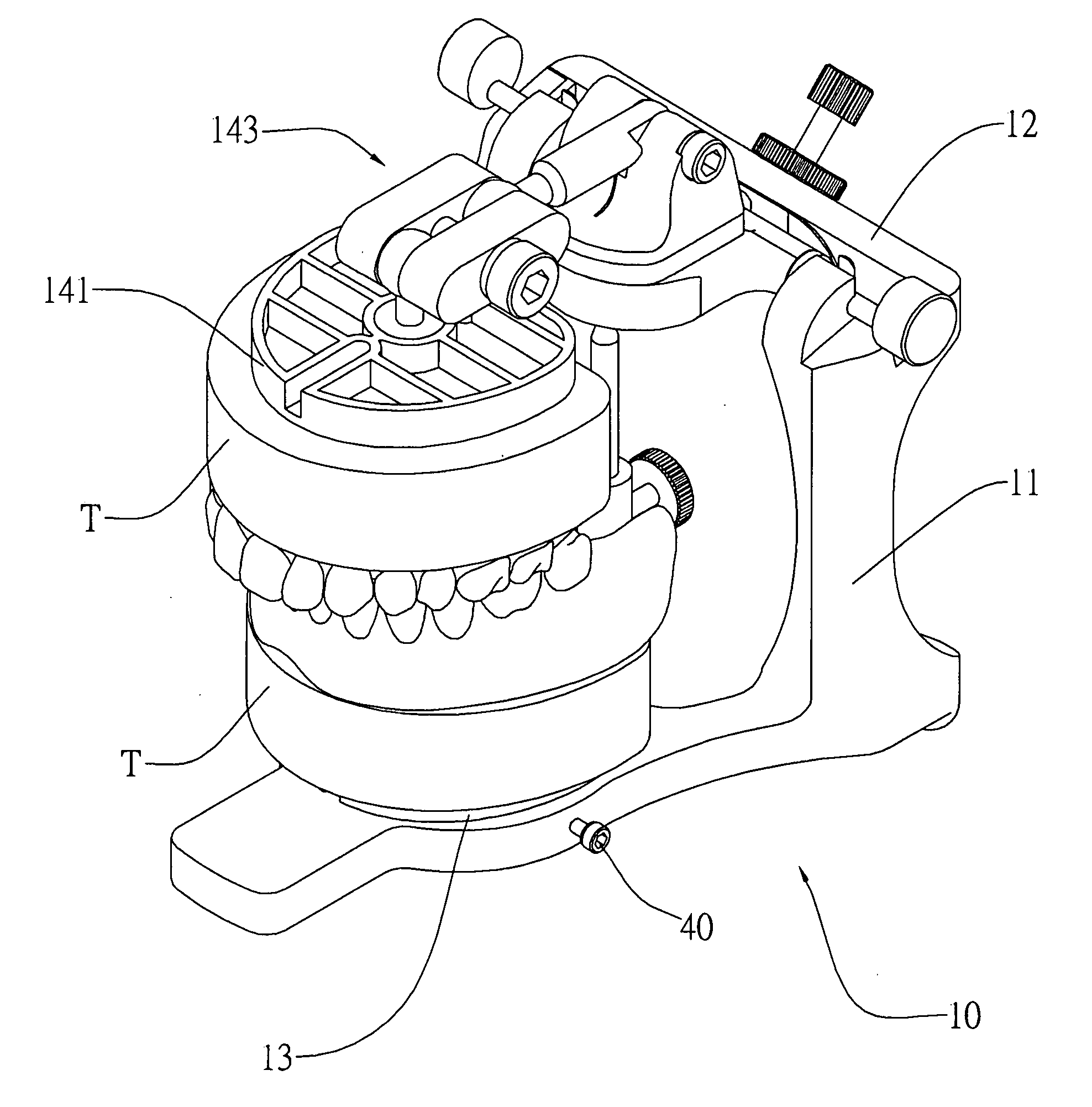

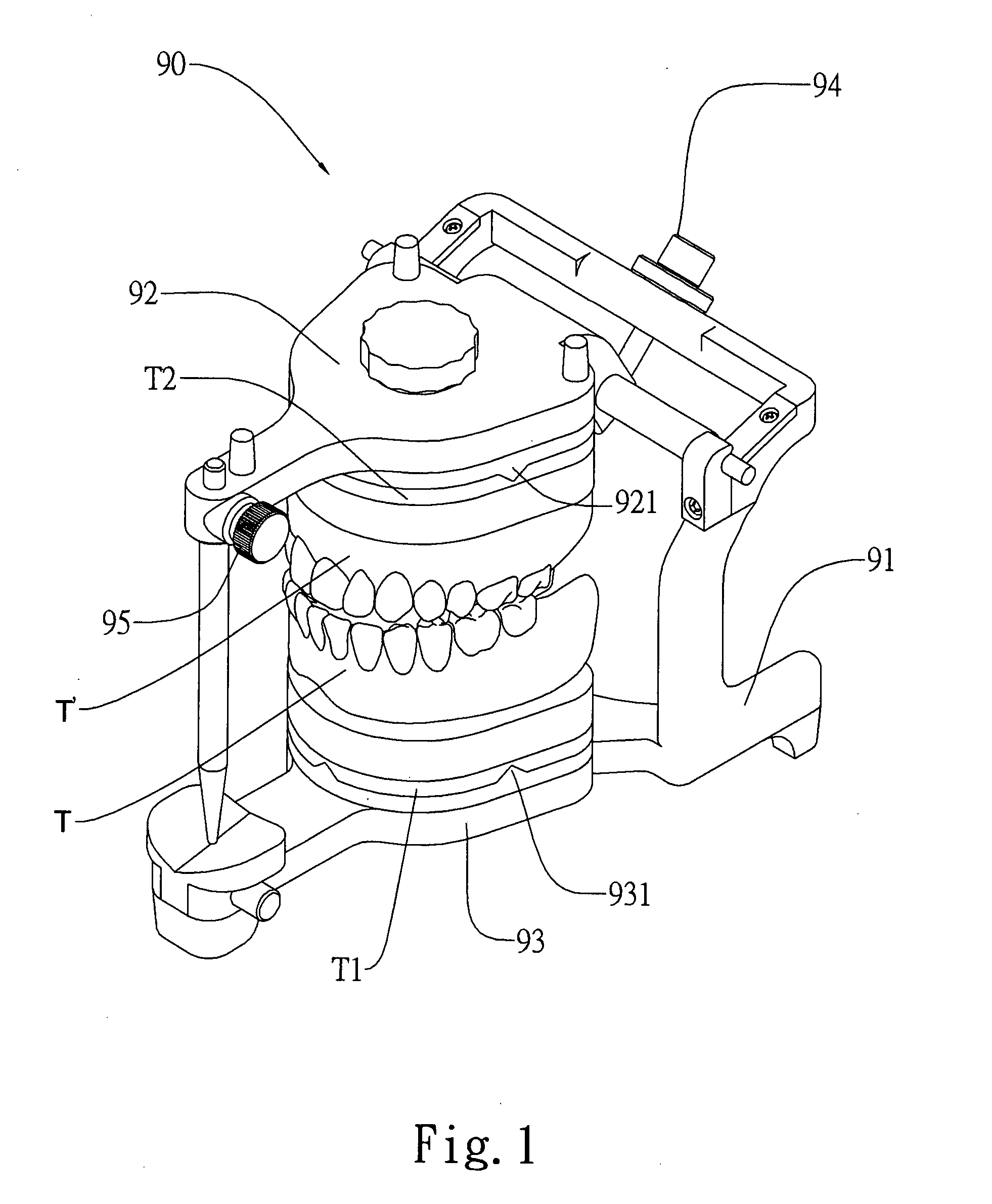

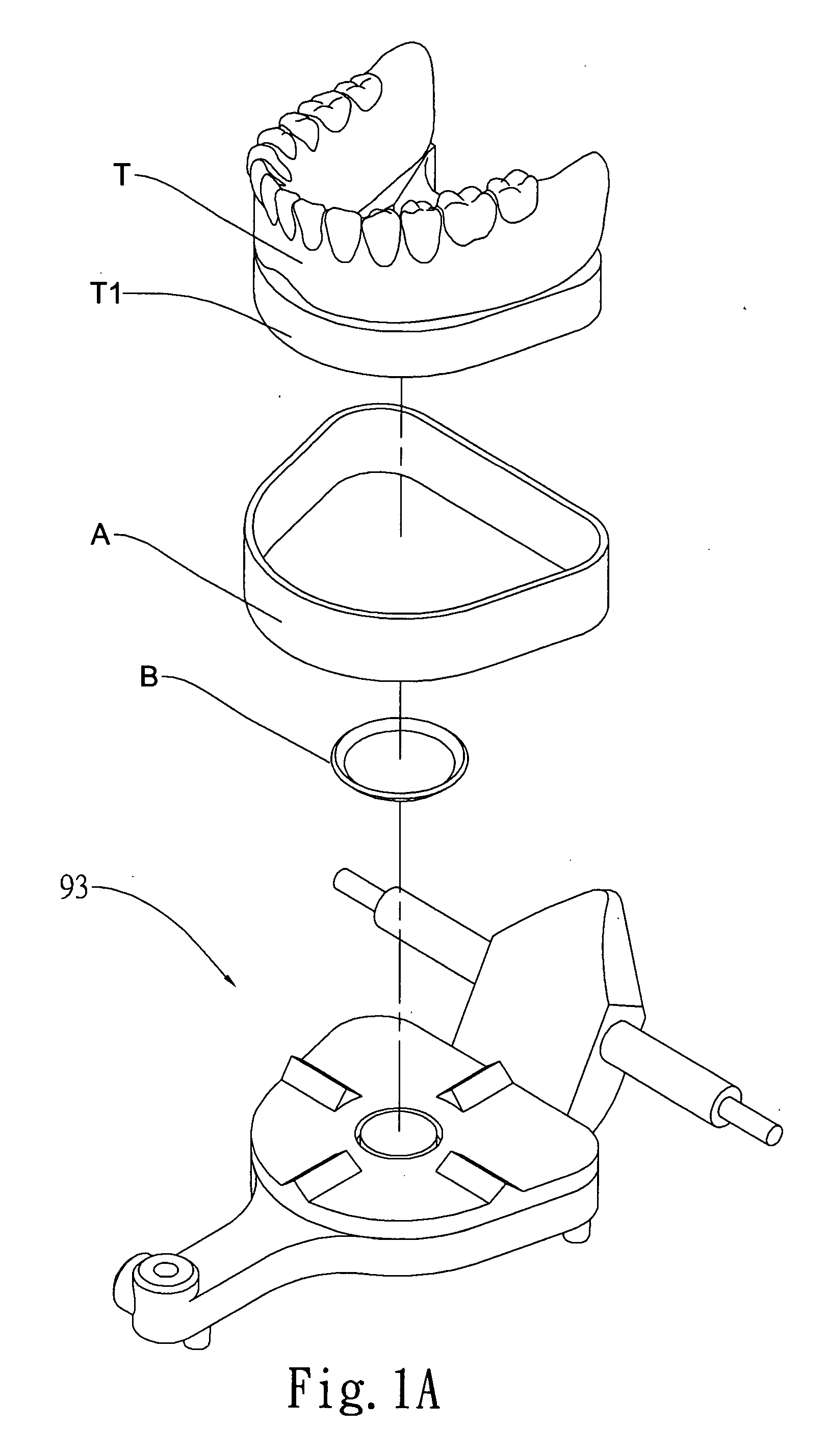

Tooth mold retaining frame

InactiveUS7686278B2Avoid manufacturing errorsEasy to viewLiquid surface applicatorsImpression capsUpper teethEngineering

A tooth mold retaining frame comprises an L shape seat; a pivotal block; a universal connector; a first positioning block; a second positioning block; and a first fine adjust unit. By using the first fine adjust unit, second fine adjust unit and the fine-adjust device, an upper teeth mold, and a lower teeth mold can move with respect to one another precisely. By a universal connector, the upper teeth mold can move three directionally and can lift or descend proportionally so as to avoid the error in manufacturing of the teeth mold. Thus the teeth mold can be made precisely and the condition of the teeth mold can be viewed conveniently. Furthermore, the teeth mold can be sent directly without needing to send the teeth frame. Thus, the manufacturer can make the teeth mold continuously without affecting the working time.

Owner:SONG YOUNG INT

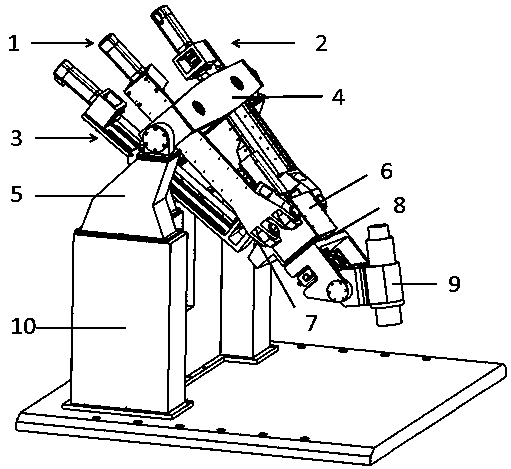

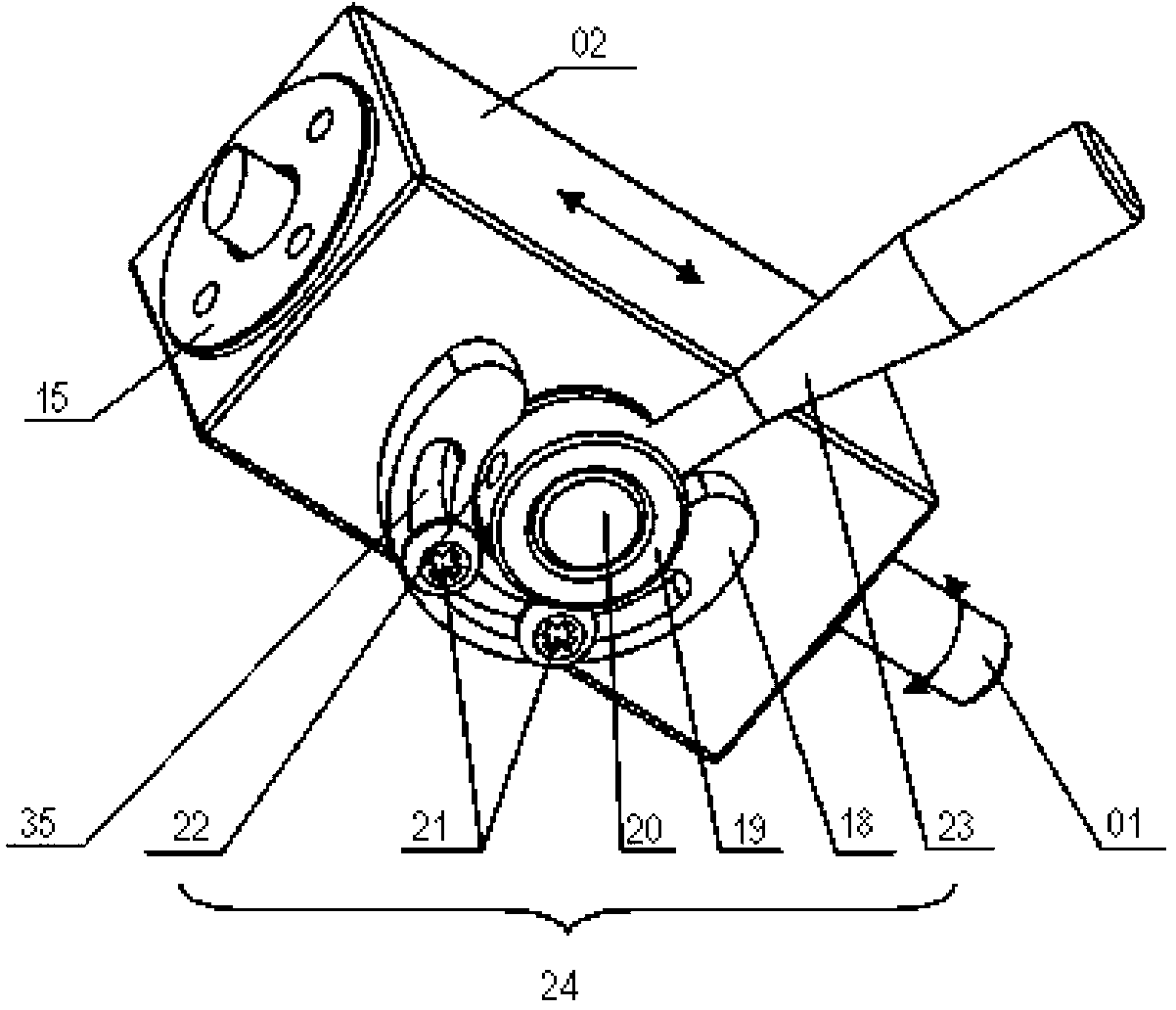

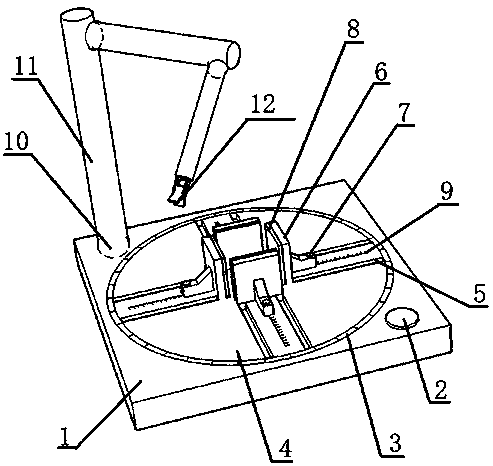

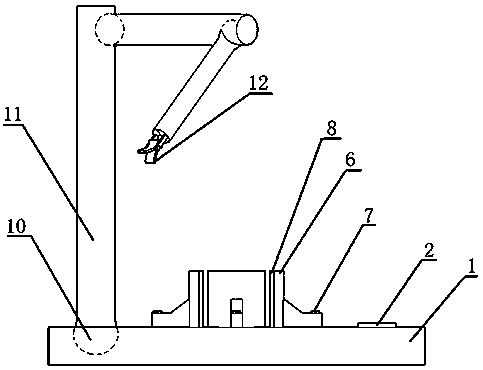

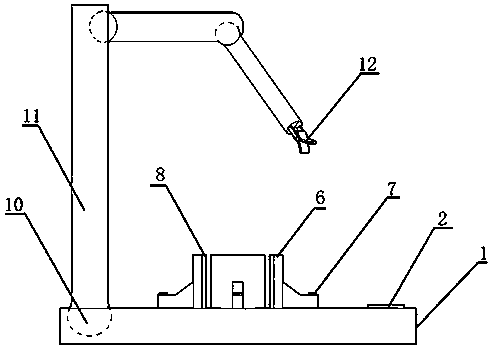

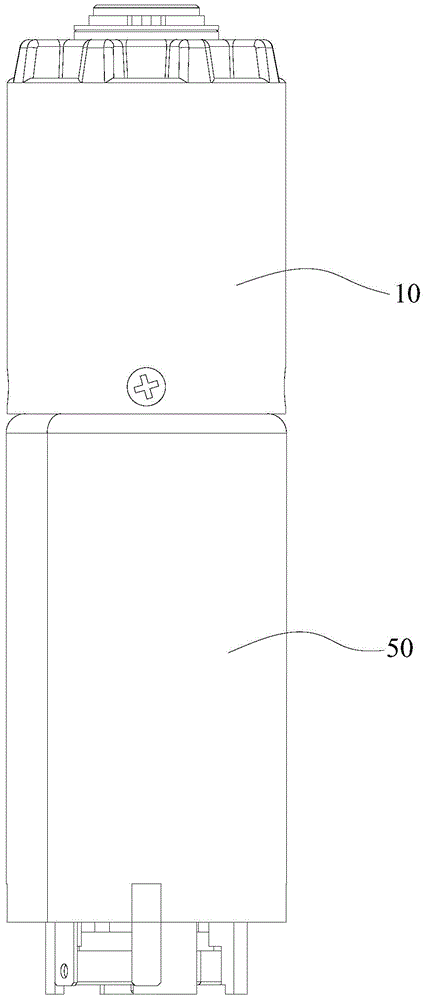

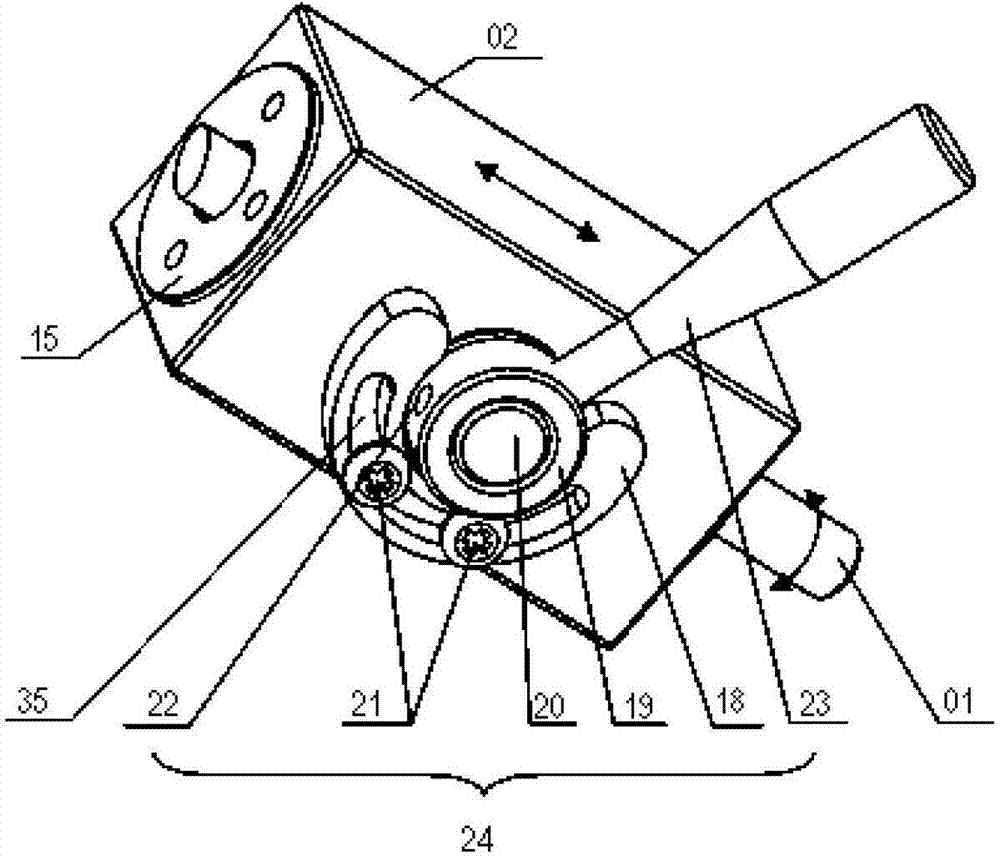

Five-degree-of-freedom precise series-parallel robot with mobile platform additional constraints

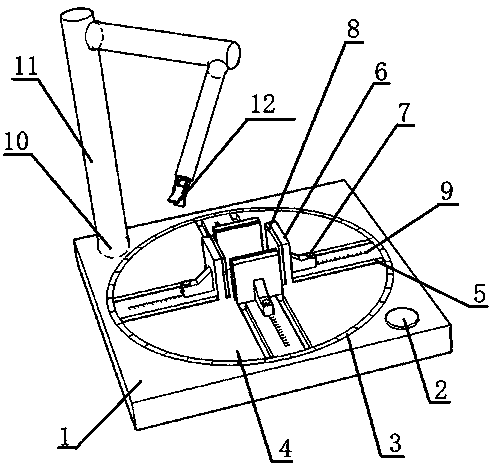

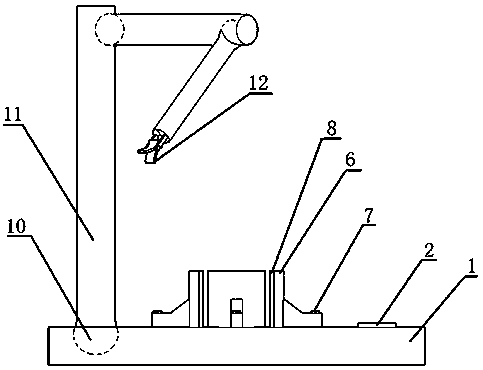

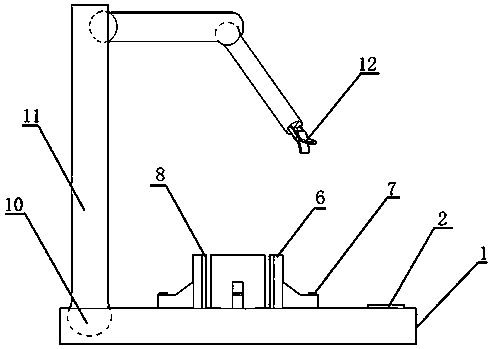

InactiveCN108500953AHigh movement precisionAvoid manufacturing errorsProgramme-controlled manipulatorEngineering

The invention relates to a five-degree-of-freedom precise series-parallel robot with mobile platform additional constraints. The robot comprises a rotating platform, a base support, a mobile platform,a precise spherical hinge connection pair, a first series connection joint, a movement tail end, a base, a first rod, a second rod and a third rod, wherein the first rod and the second rod are the same in structure, and the two rods penetrate through a first hinge and are connected to the rotating platform; the third rod is connected to the base through a hinge and is located below the first rodand the second rod; and one end of the first rod and one end of the second rod are connected with the mobile platform through a second hinge, and one end of the third rod is connected with the mobileplatform through the precise spherical hinge connection pair. According to the five-degree-of-freedom precise series-parallel robot with the mobile platform additional constraints, due to the structural characteristic that the precise spherical hinge connection pair is connected between the third rod and the mobile platform, the mobile platform is subjected to the additional constraints, the motion space of the mobile platform is a plane perpendicular to the ground, the precision is relatively high, the overall structure is provided with fewer joints and parts, and machining, manufacturing andassembling are convenient.

Owner:SHANGHAI UNIV

Solder resist layer manufacturing method, printed circuit board manufacturing method and printed circuit board

InactiveCN111050487AInhibit sheddingAvoid voidsNon-metallic protective coating applicationSolder maskPrinting ink

The invention discloses a solder resist layer manufacturing method, a printed circuit board manufacturing method and a printed circuit board. The solder resist layer manufacturing method comprises thefollowing steps: step 1, firstly, filling and leveling up a gap between thick copper on the printed circuit board by using printing ink; and step 2, performing solder resist pattern printing on the printed circuit board. The method of firstly filling and then solder resist is adopted. As the height difference between the base material area and the thick copper surface area is large, the lower base material area is firstly filled and leveled up by using solder resist ink, i.e., the height is basically equal to that of the thick copper surface, and then solder resist manufacturing is completedby using whole board ink printing so that the overall flatness of board surface ink is ensured; meanwhile, the etching amount of the ink side wall on the side of the base material area is reduced, thebinding force of the ink and the base material surface is increased, and ink falling can be prevented.

Owner:SHANGHAI MEADVILLE ELECTRONICS

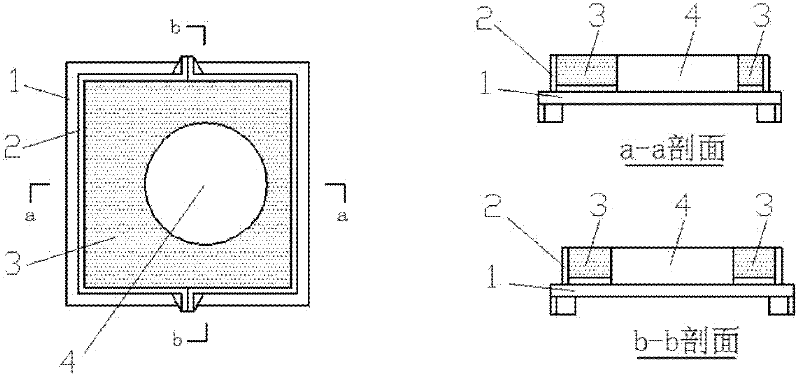

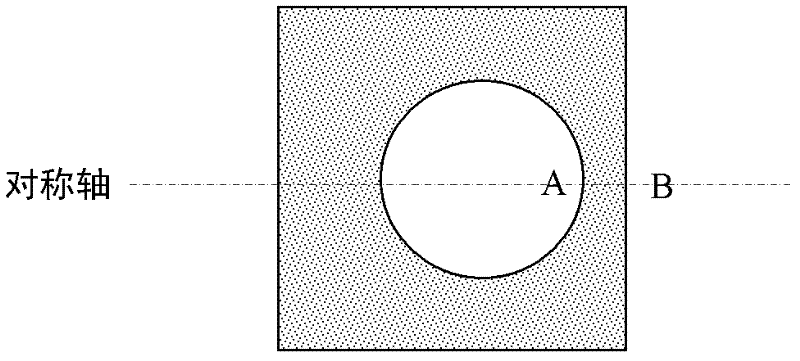

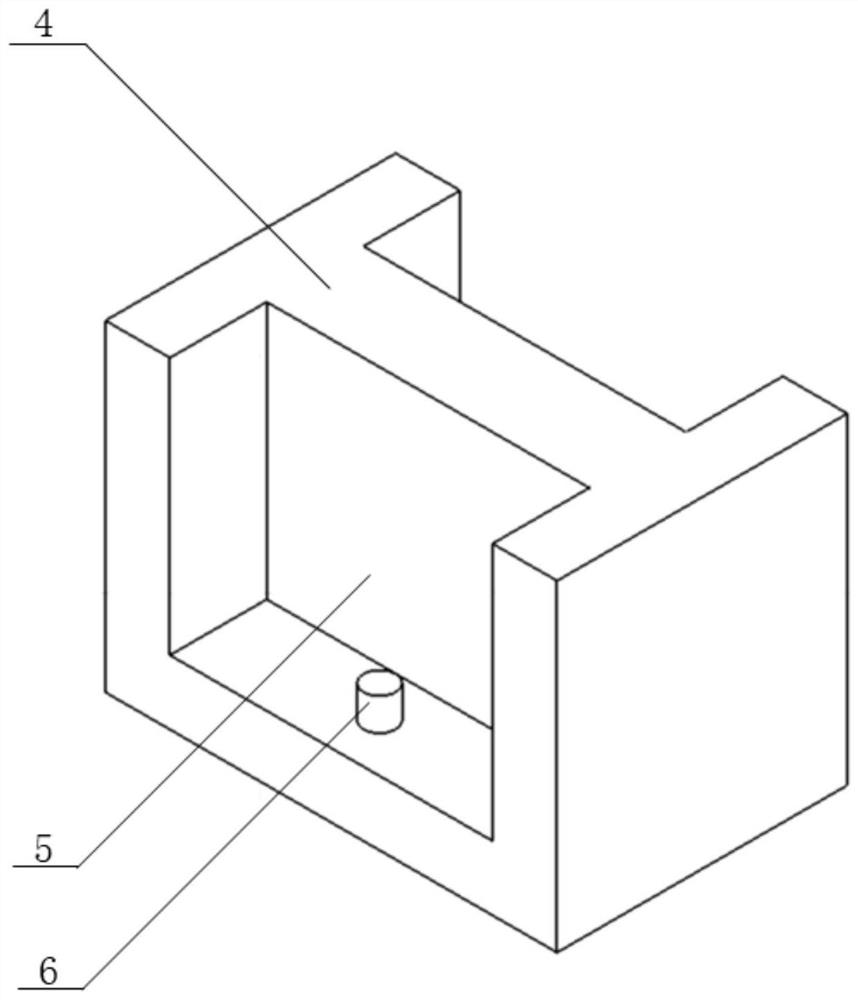

Method for testing shrinkage cracking performance of cement paste or mortar

InactiveCN102520143AEasy to crackShorten the test cyclePreparing sample for investigationMaterial testing goodsShrinkage crackingElement analysis

The invention relates to a method for testing the shrinkage cracking performance of a cement paste or a mortar. A molded test piece of a novel mold is adopted to carry out the cracking test to test the shrinkage cracking performance of the cement paste or the mortar. The mold comprises a pedestal, an outer mold and a steel cylinder; the steel cylinder is fixed on the pedestal; the outer mold is movably connected with the pedestal; and the outer mold is square, the steel cylinder is in the outer mold, and the steel cylinder which is not in the center of the square is in a unidirectional eccentric position. The ratio of the diameter of the steel cylinder to the inner side length of the outer mold, i, satisfies a case that i is greater than 0.5 and less than 1; and heights of the steel cylinder and the outer mold satisfy a case that the thickness of the molded test piece is equal to or greater than 5 times the largest particle size used in the test. The selection of the eccentric position of the steel cylinder is determined through carrying out finite element analysis on the molded test piece by ANSYS software. According to the invention, the cracking position can be foreseen, the test piece cracking can be accelerated, and the cracking can start from the outer interface.

Owner:TIANJIN UNIV

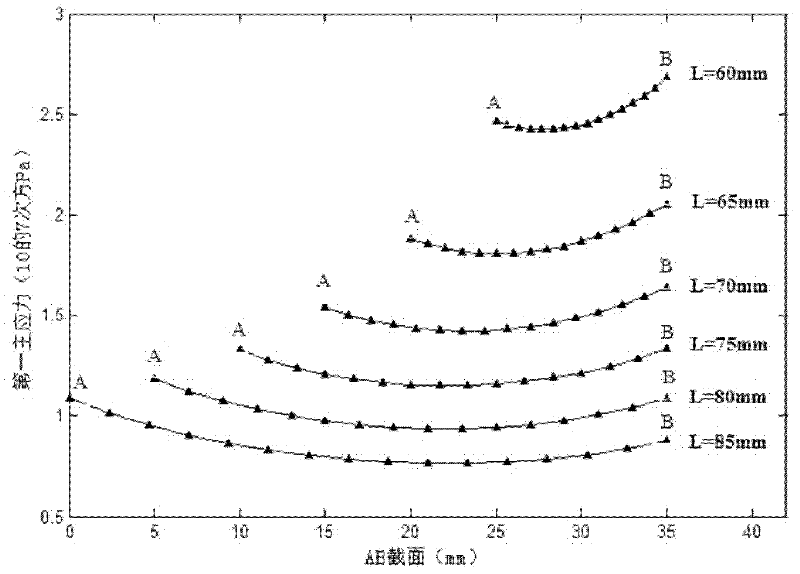

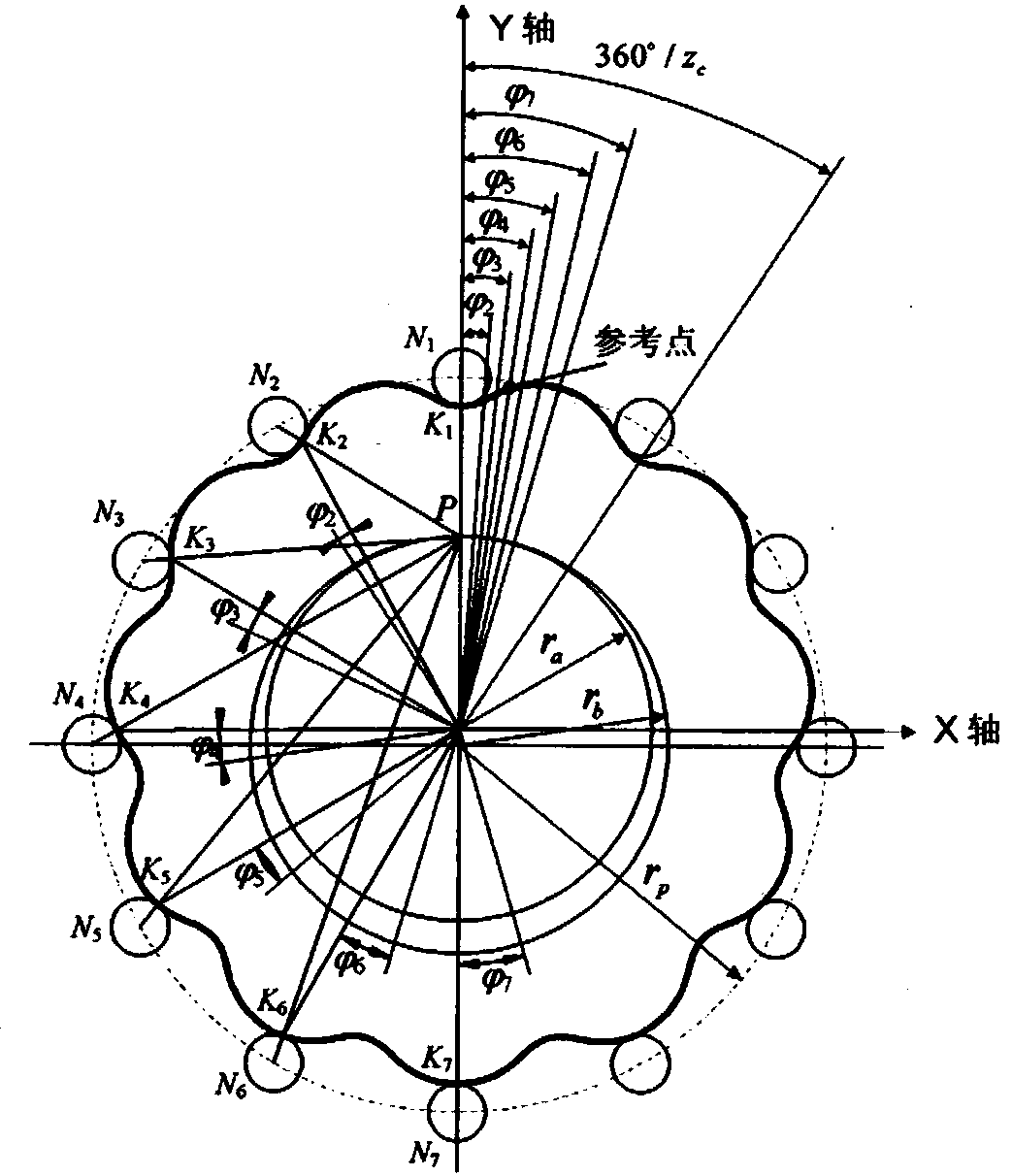

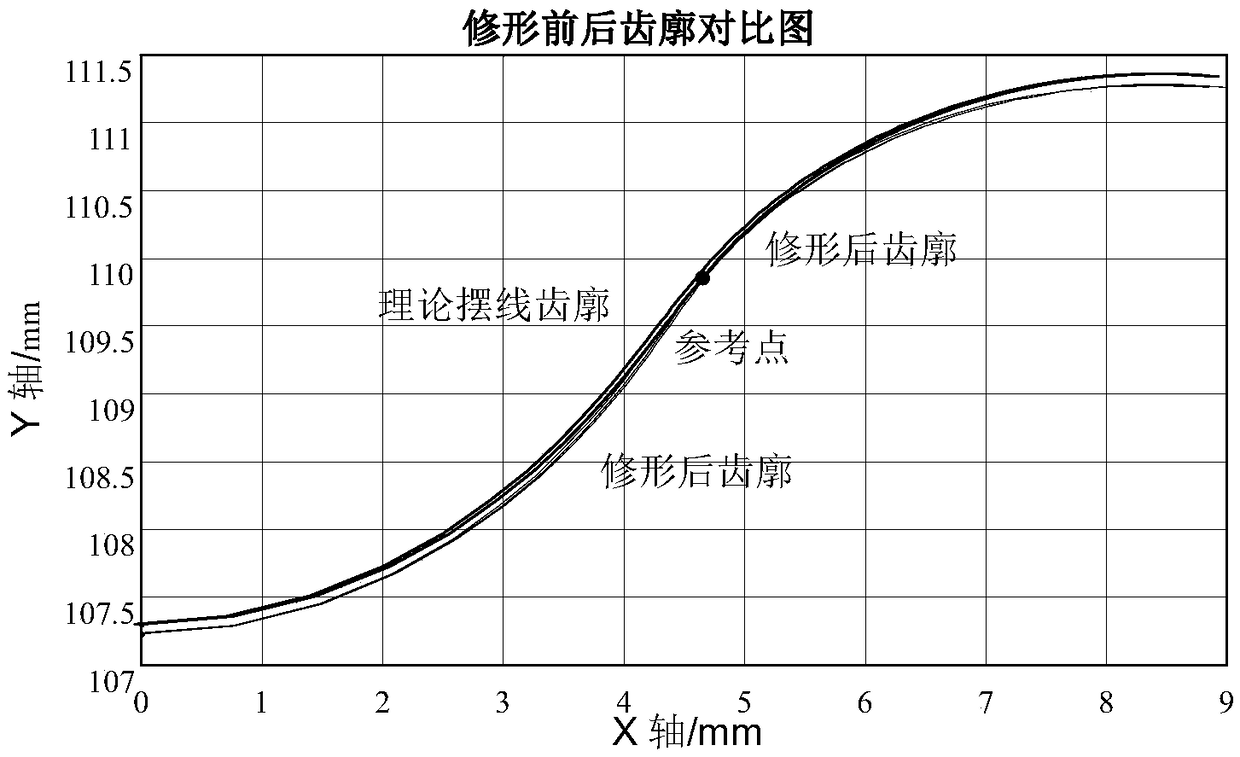

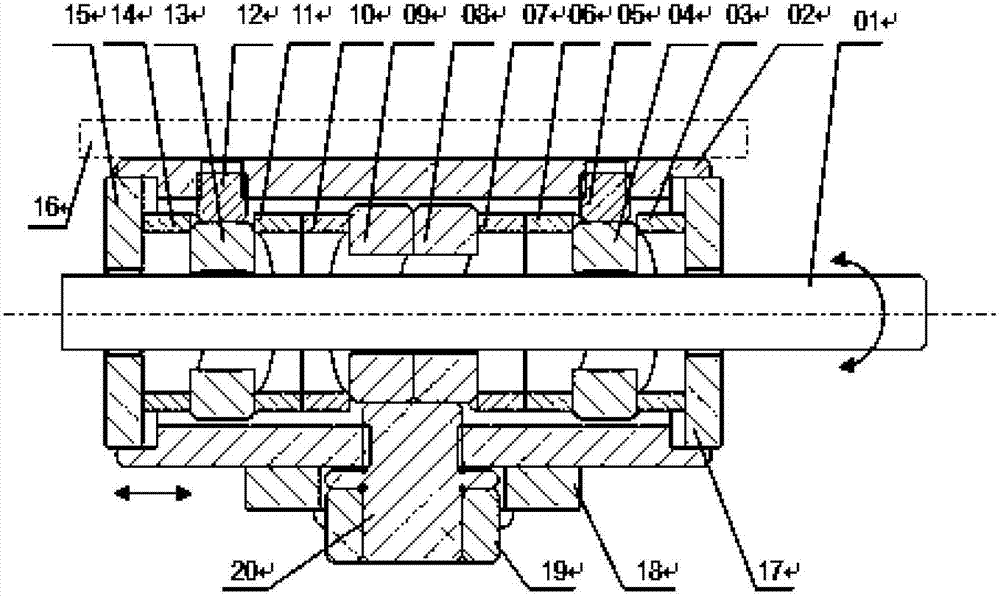

Tooth profile modification design method and system for cycloid gear of RV speed reducer

ActiveCN108331899AAvoid manufacturing errorsPre-control transmission errorGeometric CADPortable liftingEngineeringDesign methods

The invention relates to a tooth profile modification design method and system for a cycloid gear of an RV speed reducer, and belongs to the technical field of design of the RV speed reducers. According to the tooth profile modification design method for the cycloid gear of the RV speed reducer, at least two factors of a manufacturing error, a mounting error, a system bearing deformation and a temperature variable are used as boundary conditions, and a modification amount is used as an optimization variable, so as to build a target function with a minimum transmission error and a minimum hysterisis error of the cycloid gear is built; and the target function is solved to obtain a tooth profile modification amount and a modification function curve of the cycloid gear. The tooth profile modification design method disclosed by the invention comprehensively considers at least two factors of the manufacturing error, the mounting error, the system bearing deformation and the temperature variable, and influences caused by the at least two factors on the modification amount is used as the boundary conditions to determine the modification amount, so that the obtained modification amount andthe modification function curve can pre-control the transmission error and the hysterisis error of the RV speed reducer under an actual working condition, and the aim of improving the motion precisionof the RV speed reducer is fulfilled.

Owner:HENAN UNIV OF SCI & TECH

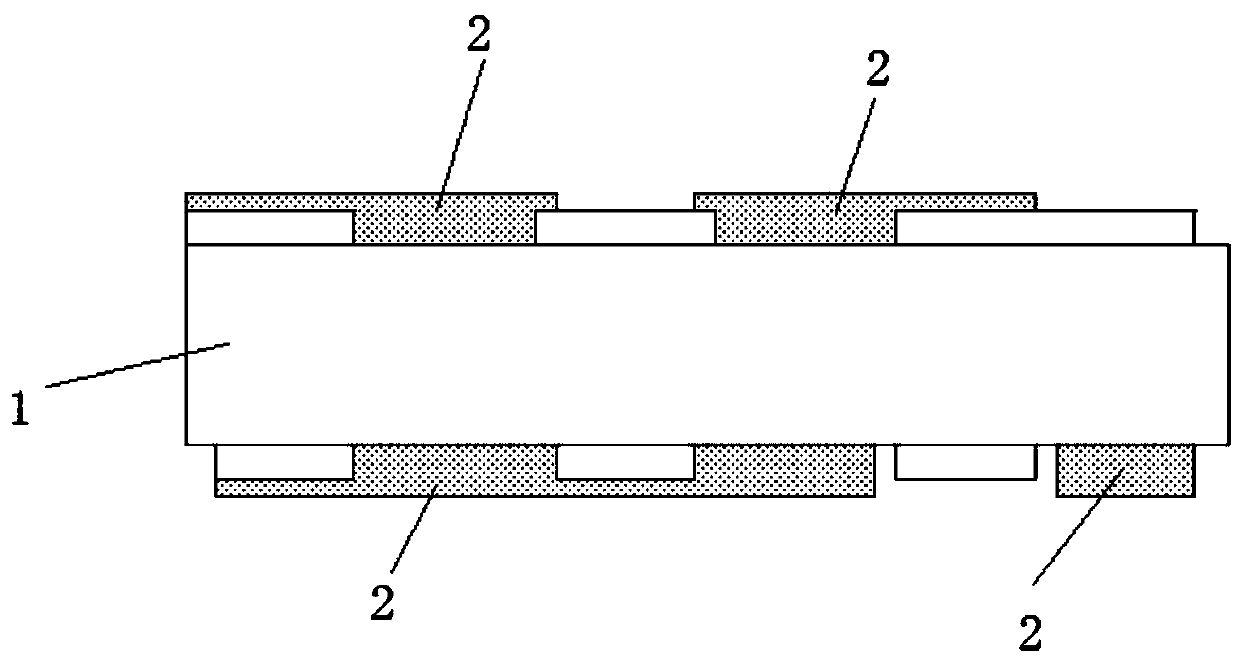

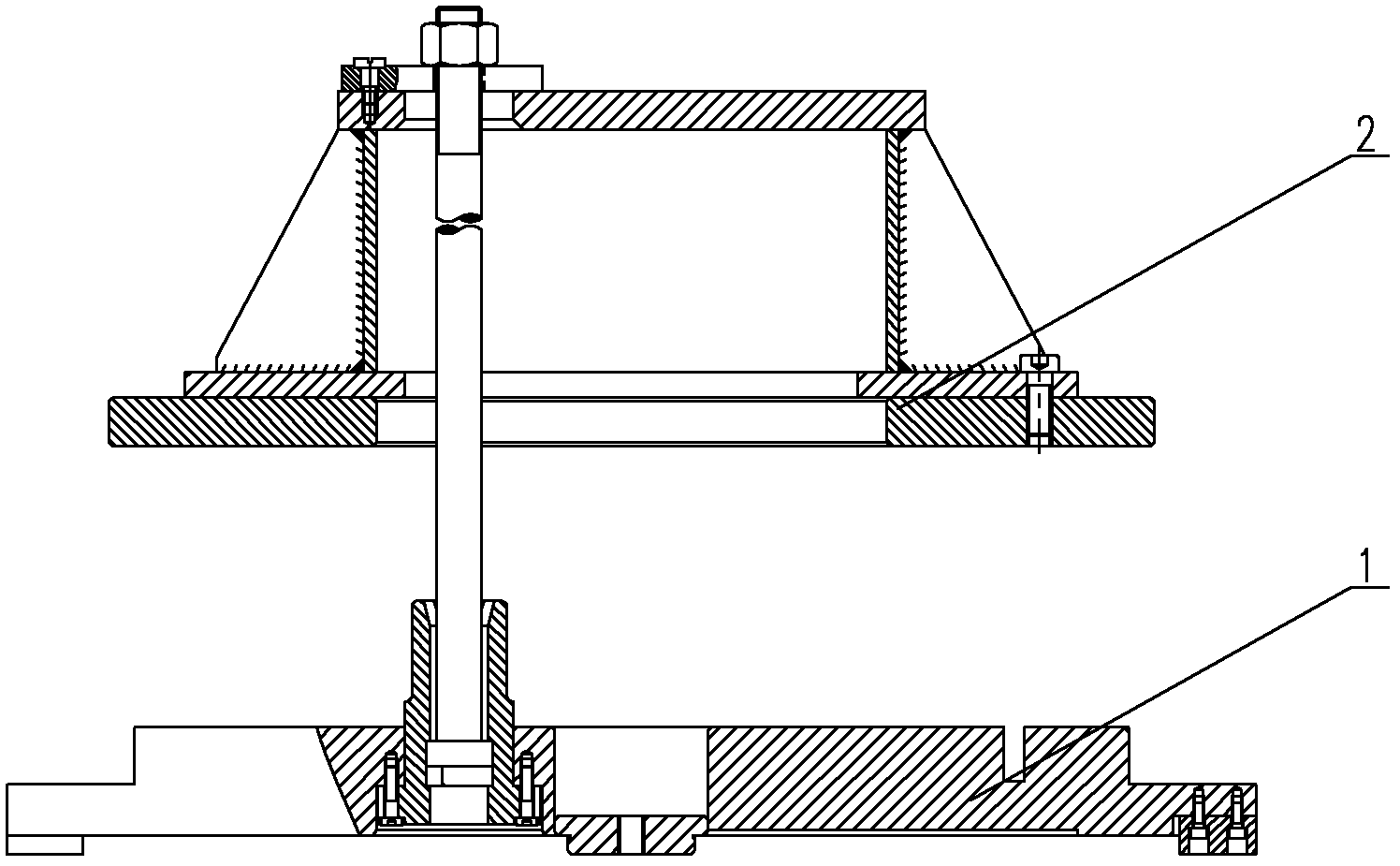

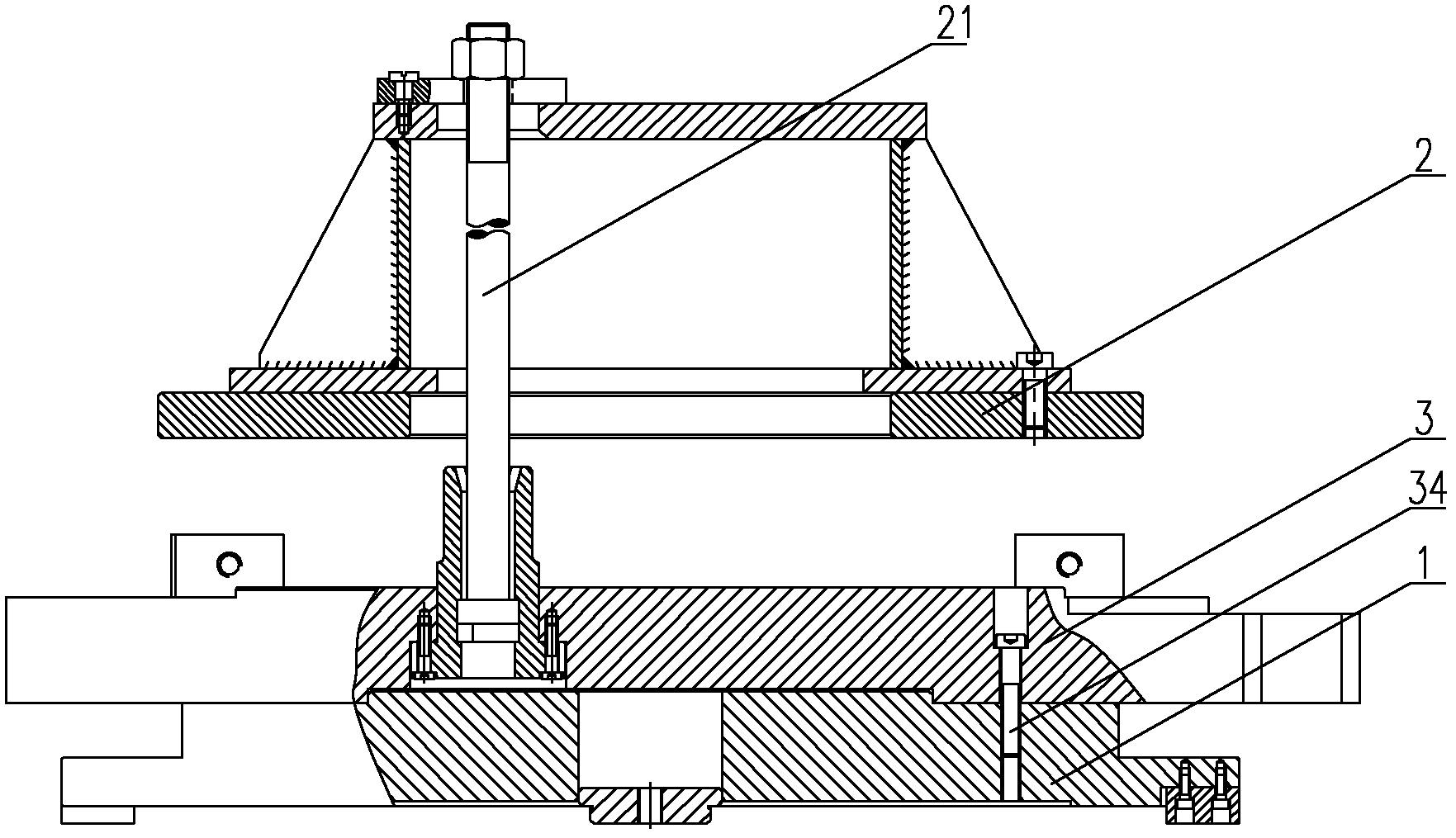

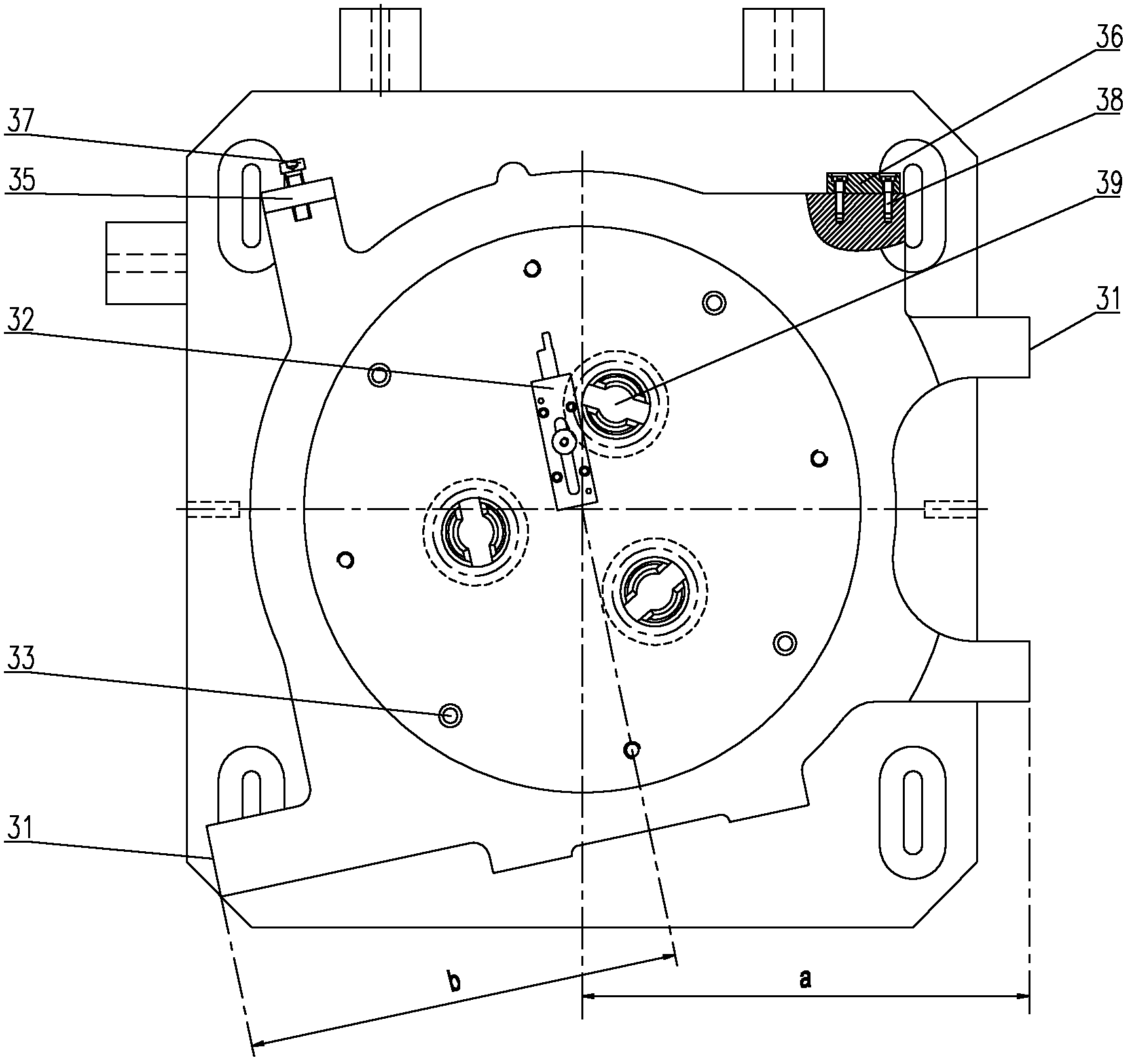

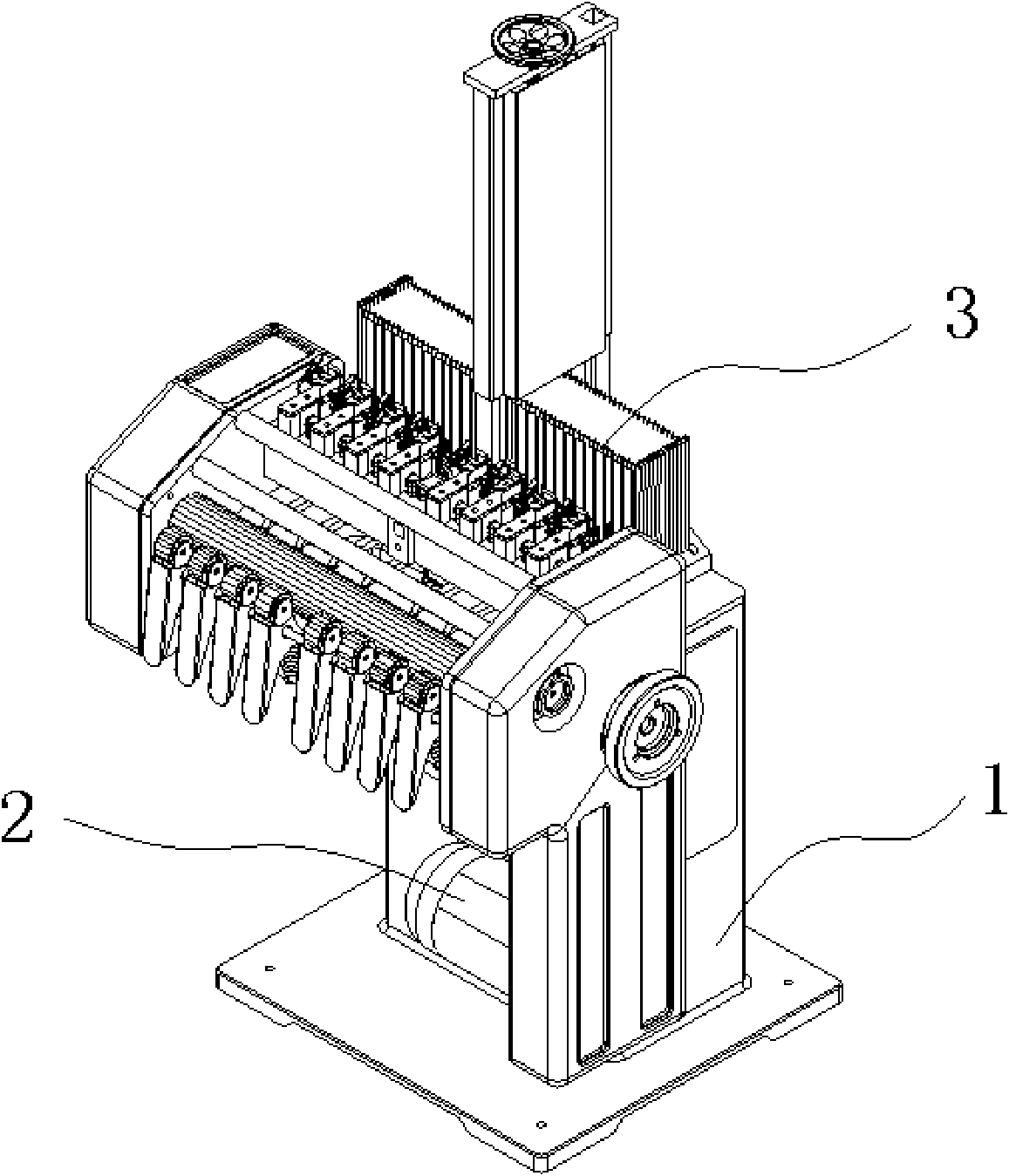

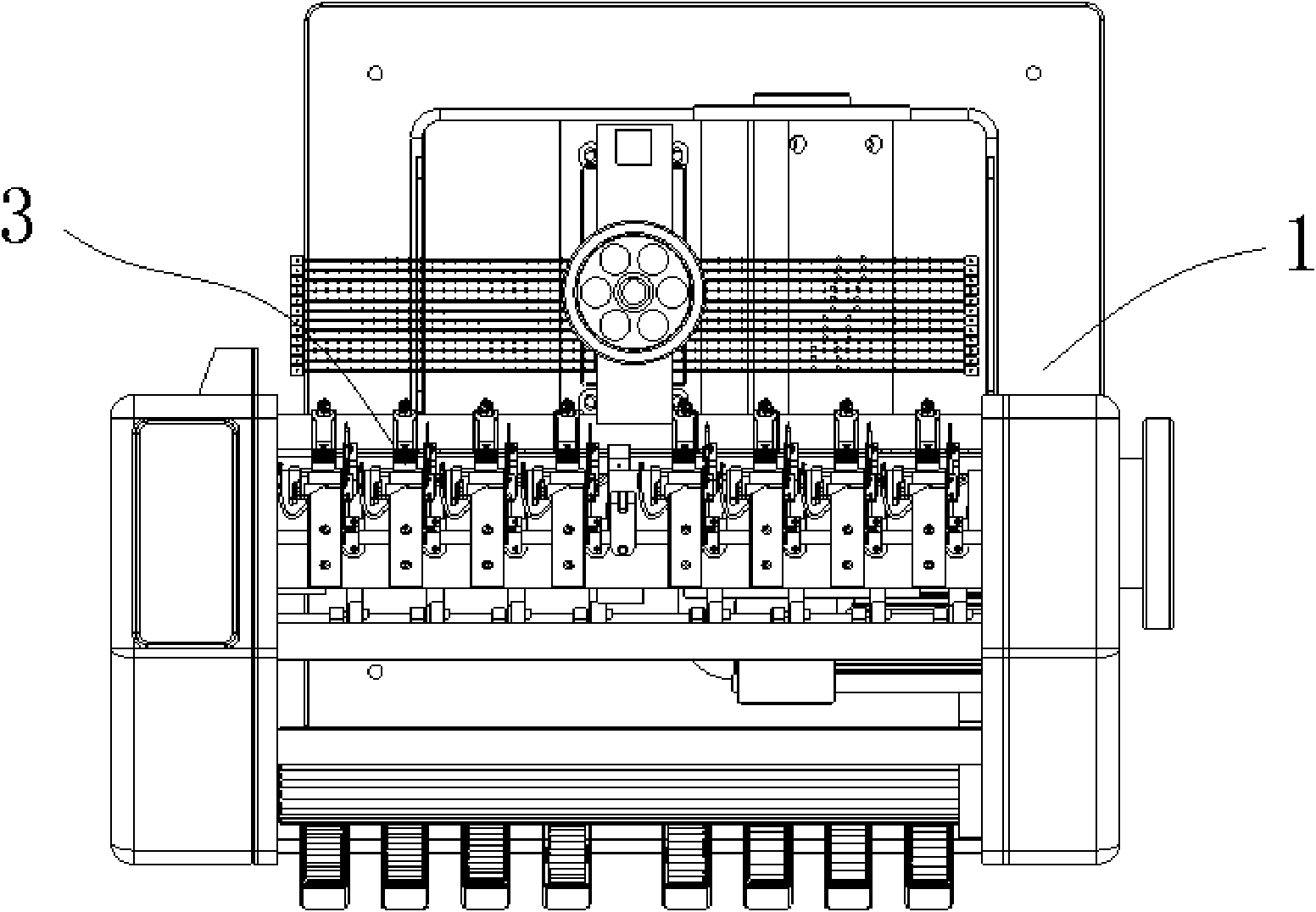

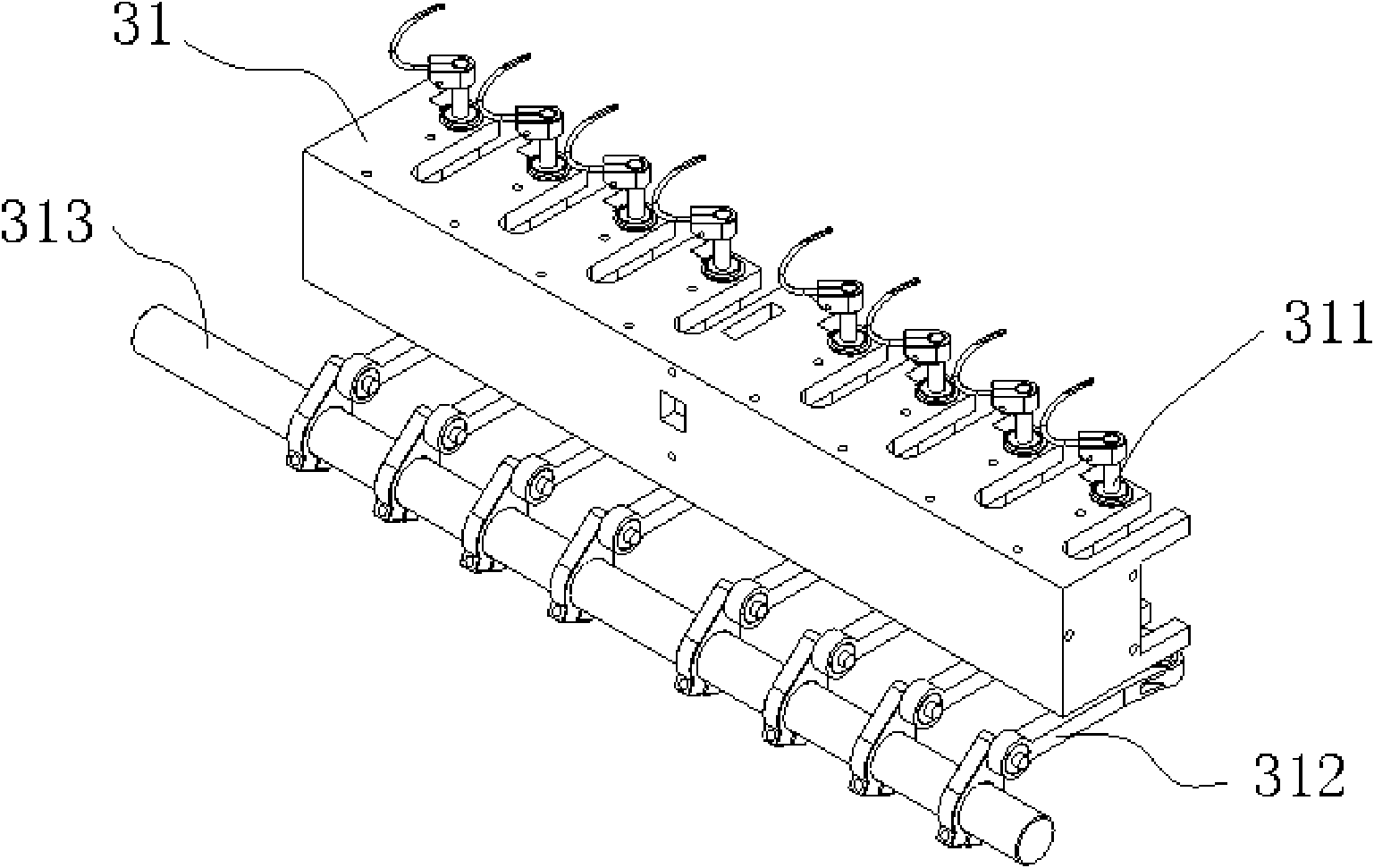

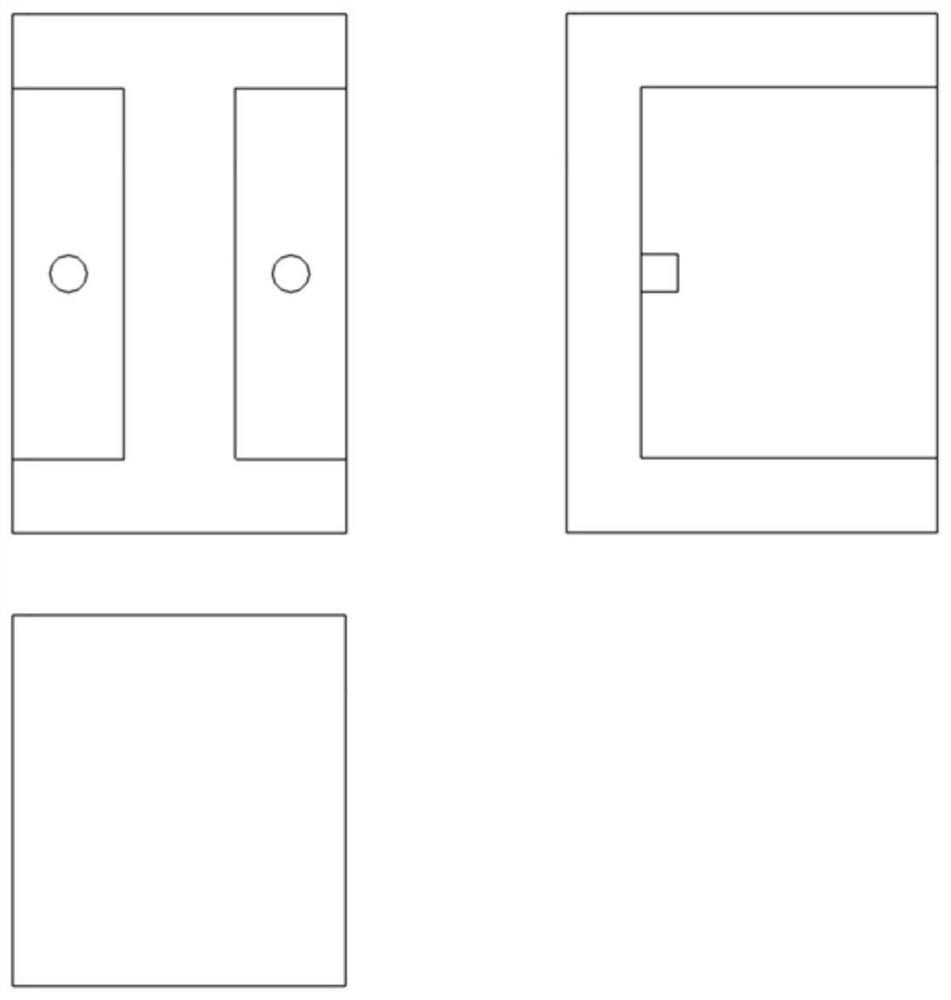

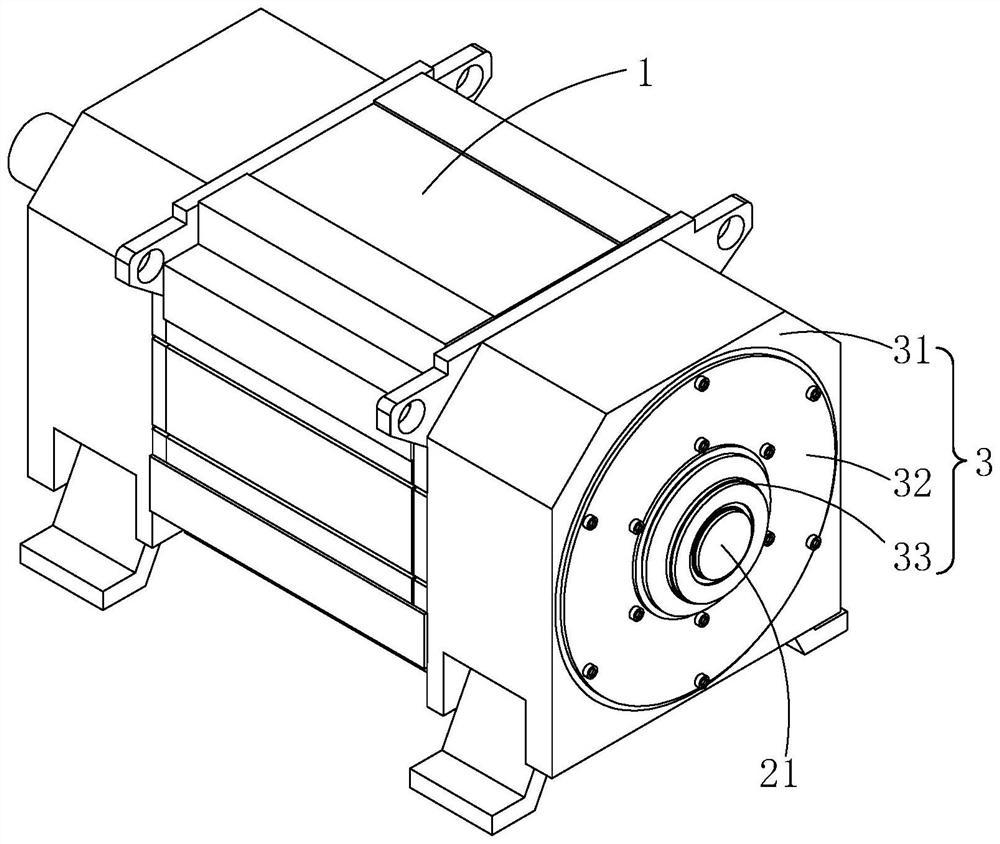

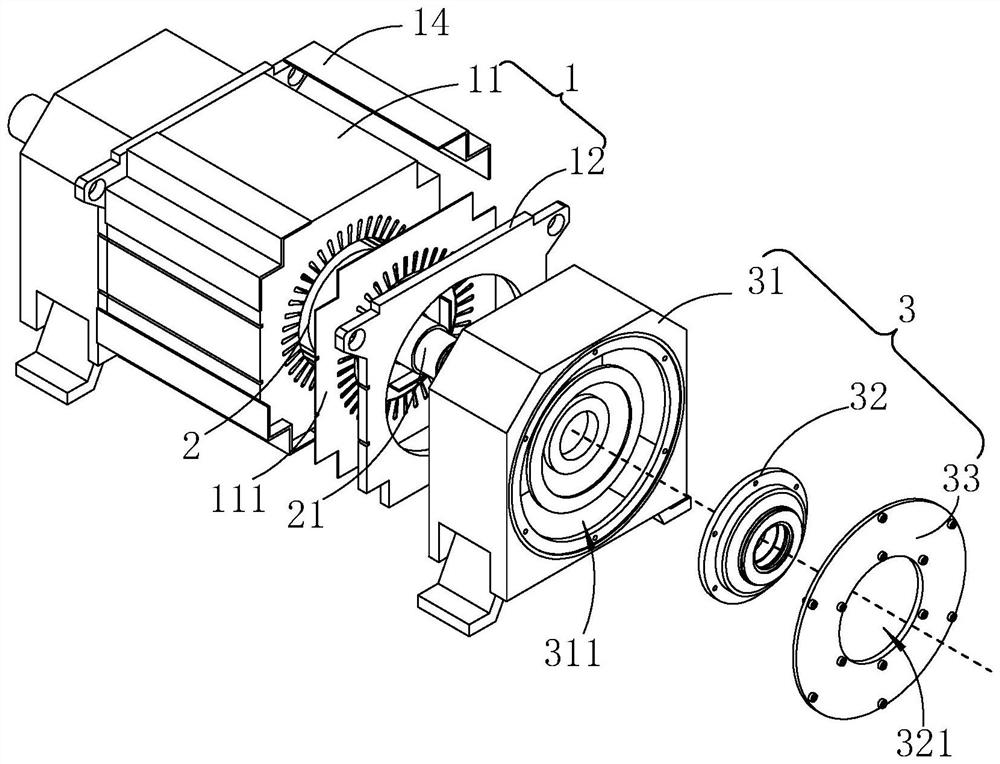

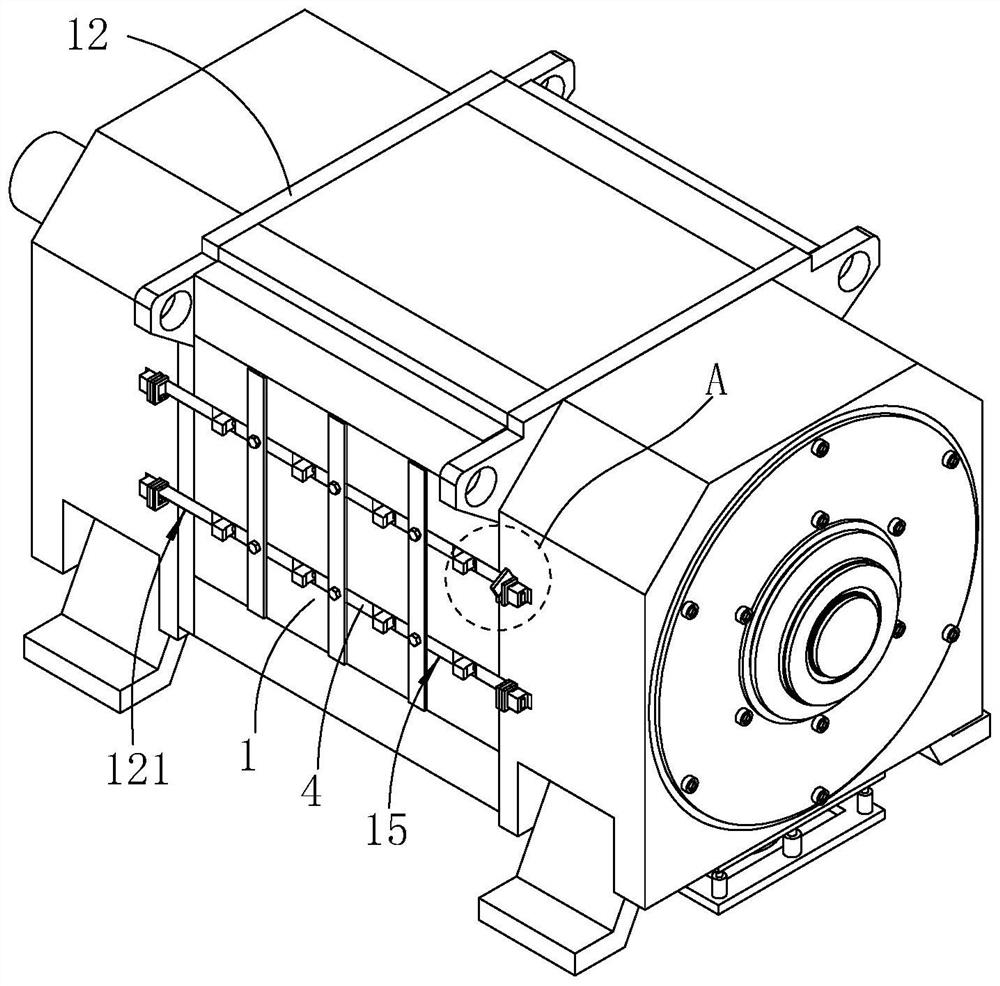

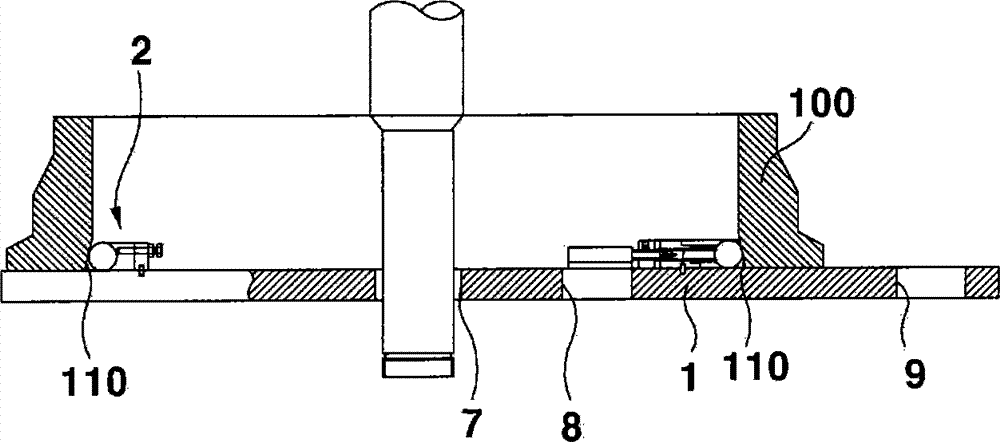

Machine tool fixture

ActiveCN102513848AImprove machining accuracyImprove processing efficiencyPositioning apparatusMetal-working holdersEngineeringMachine tool

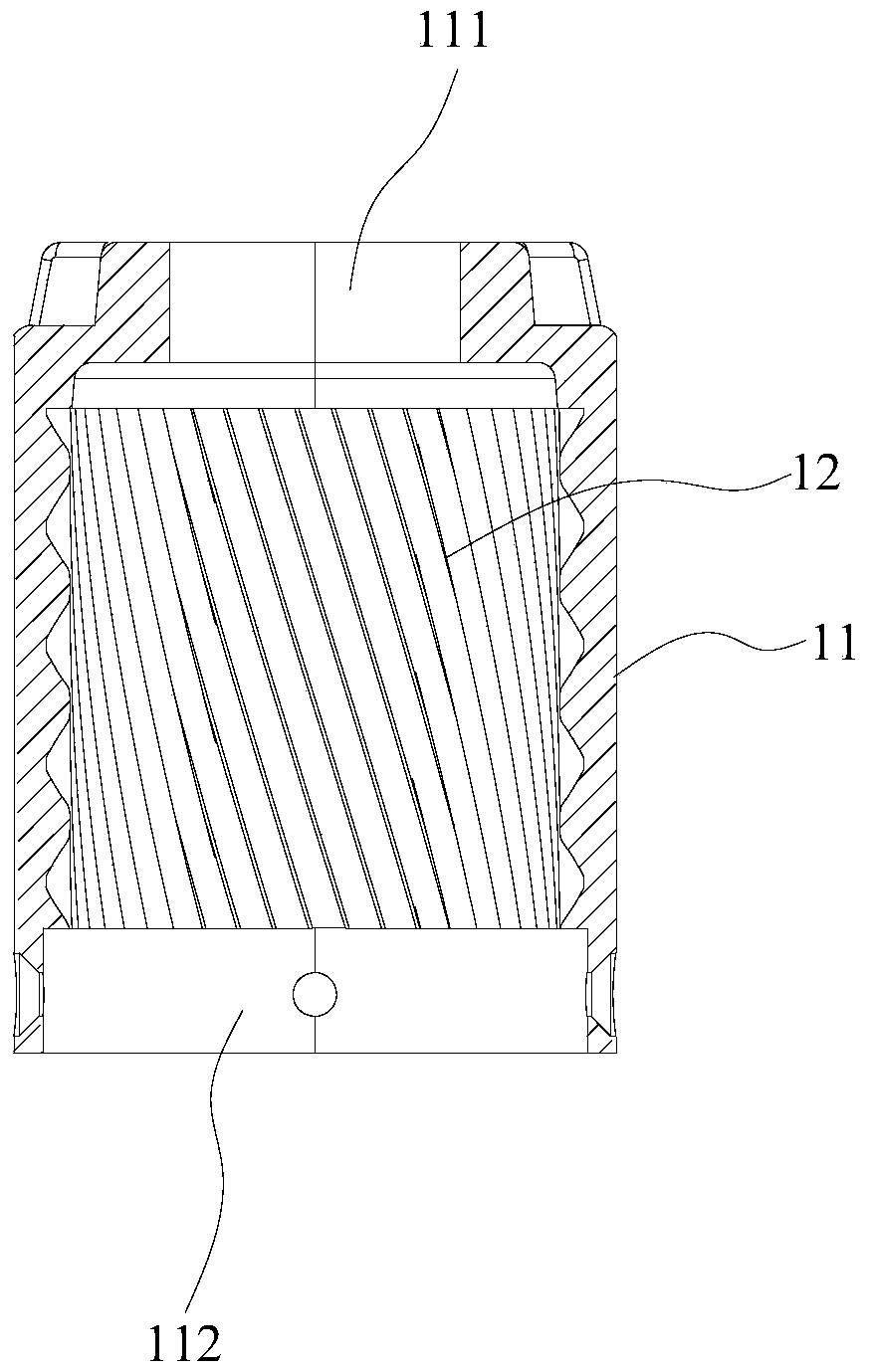

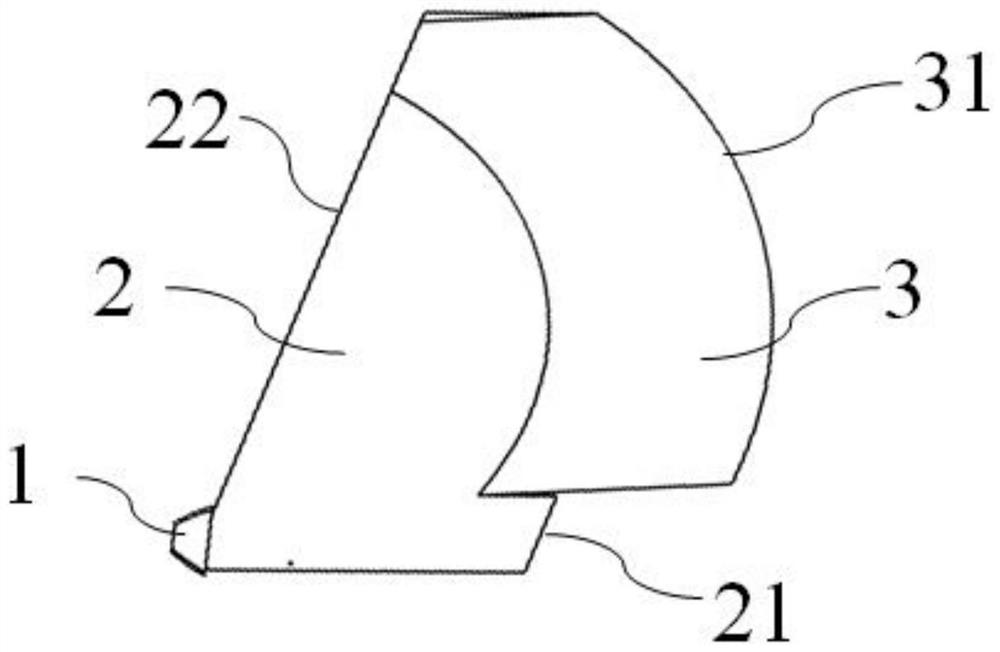

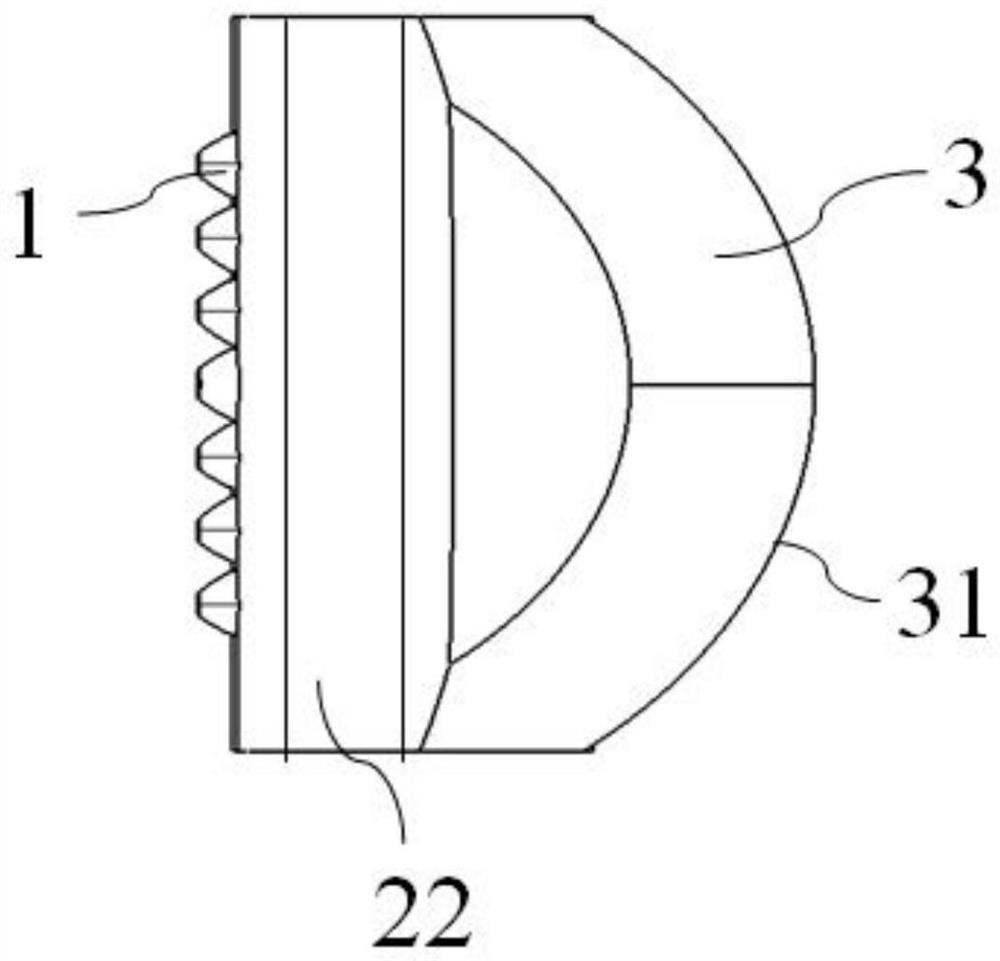

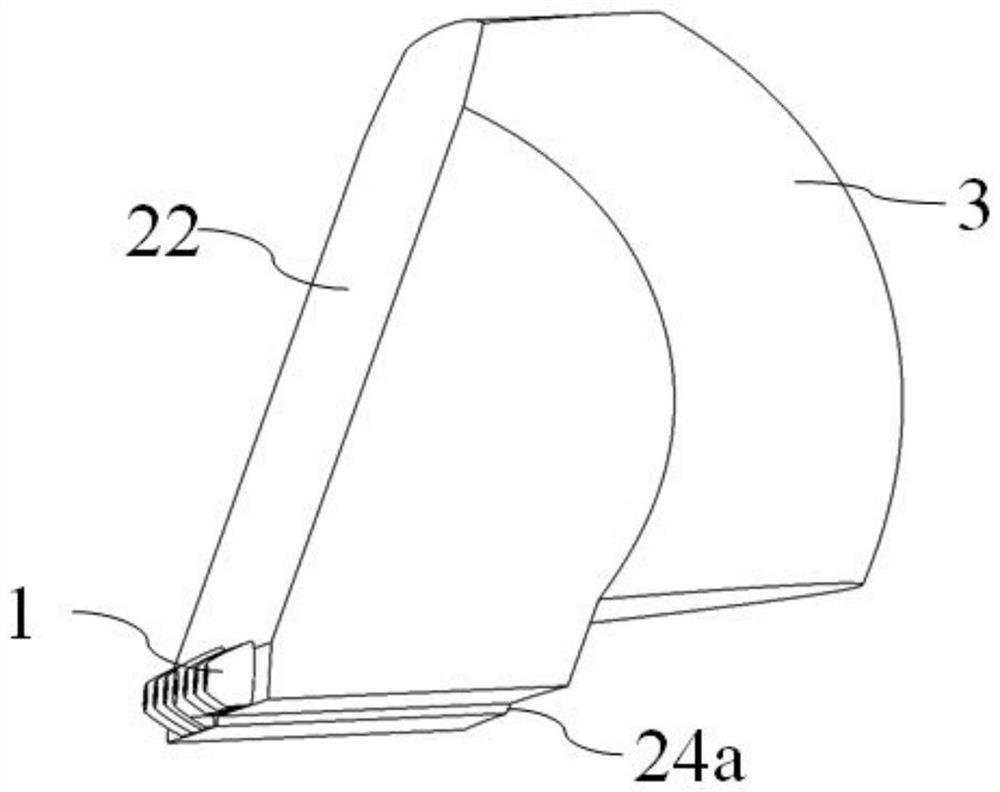

The invention discloses a machine tool fixture, which comprises a bottom plate (1), a clamping device (2) and a positioning plate (3), wherein the bottom plate (1) is used for supporting a workpiece, the clamping device (2) is used for fixing the workpiece, and the positioning plate (3) provides a detecting reference surface (31) for the workpiece and is arranged between the bottom plate (1) and the clamping device (2). The center of the positioning plate (3) and the center of the workpiece are arranged on the axis of a spindle of a machine tool for machining the workpiece, and the distance from the center of the positioning plate (3) to the reference surface (31) is a reference distance. By the aid of the machine tool fixture, a machining coordinate system can be provided for the workpiece, the reference surface in the same coordinate system can also be provided, and the requirements of the workpiece on machining and detecting are met. Compared with the prior art, the machine tool fixture has the advantages that the machining coordinate system and a detecting coordinate system do not need to be built respectively, so that manufacture errors caused by coordinate transformation are avoided, and workpiece machining precision and workpiece machining efficiency are greatly improved.

Owner:CSR ZHUZHOU ELECTRIC CO LTD

Tooth mold retaining frame

InactiveUS20080272271A1Avoid manufacturing errorsEasy to viewImpression capsLiquid surface applicatorsUpper teethEngineering

A tooth mold retaining frame comprises an L shape seat; a pivotal block; a universal connector; a first positioning block; a second positioning block; and a first fine adjust unit. By using the first fine adjust unit, second fine adjust unit and the fine-adjust device, an upper teeth mold, and a lower teeth mold can move with respect to one another precisely. By a universal connector, the upper teeth mold can move three directionally and can lift or descend proportionally so as to avoid the error in manufacturing of the teeth mold. Thus the teeth mold can be made precisely and the condition of the teeth mold can be viewed conveniently. Furthermore, the teeth mold can be sent directly without needing to send the teeth frame. Thus, the manufacturer can make the teeth mold continuously without affecting the working time.

Owner:SONG YOUNG INT

Coil with a contact sleeve for electrical connection

ActiveCN1950987APrecise positioningAvoid manufacturing errorsSecuring/insulating coupling contact membersConnections effected by permanent deformationElectrical connectionSoldering

The coil has a coil former (2) provided with a channel defined between 2 side flanges and / or a pocket for reception of a winding wire, which is electrically connected to a sleeve, in turn electrically connected to a conductor or filament of an electrical cable, the electrical connections provided by deformable tongue sections of the sleeve with subsequent soldering. A first deformable tongue section of the sleeve is used for guidance of the winding wire, a second deformable tongue section acting as a fixing tongue for providing the connection with the winding wire and a third deformable tongue section used for soldering to the cable conductor or filament.

Owner:SEW-EURODRIVE GMBH & CO KG

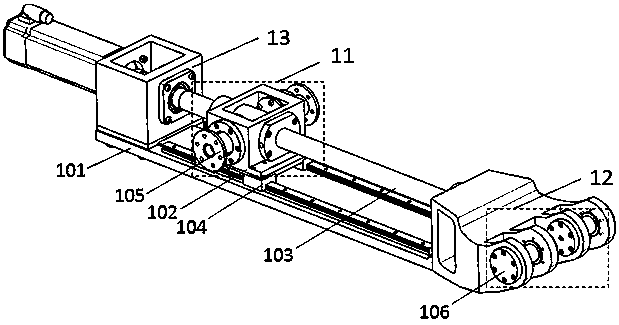

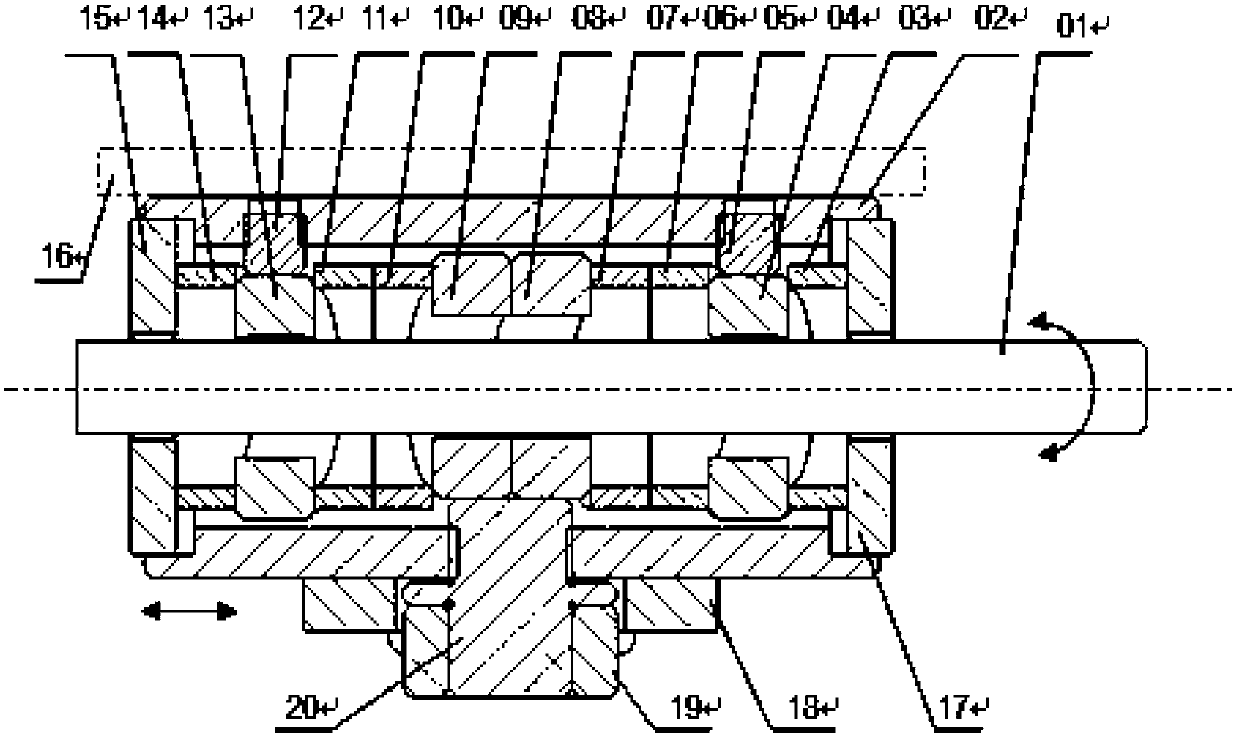

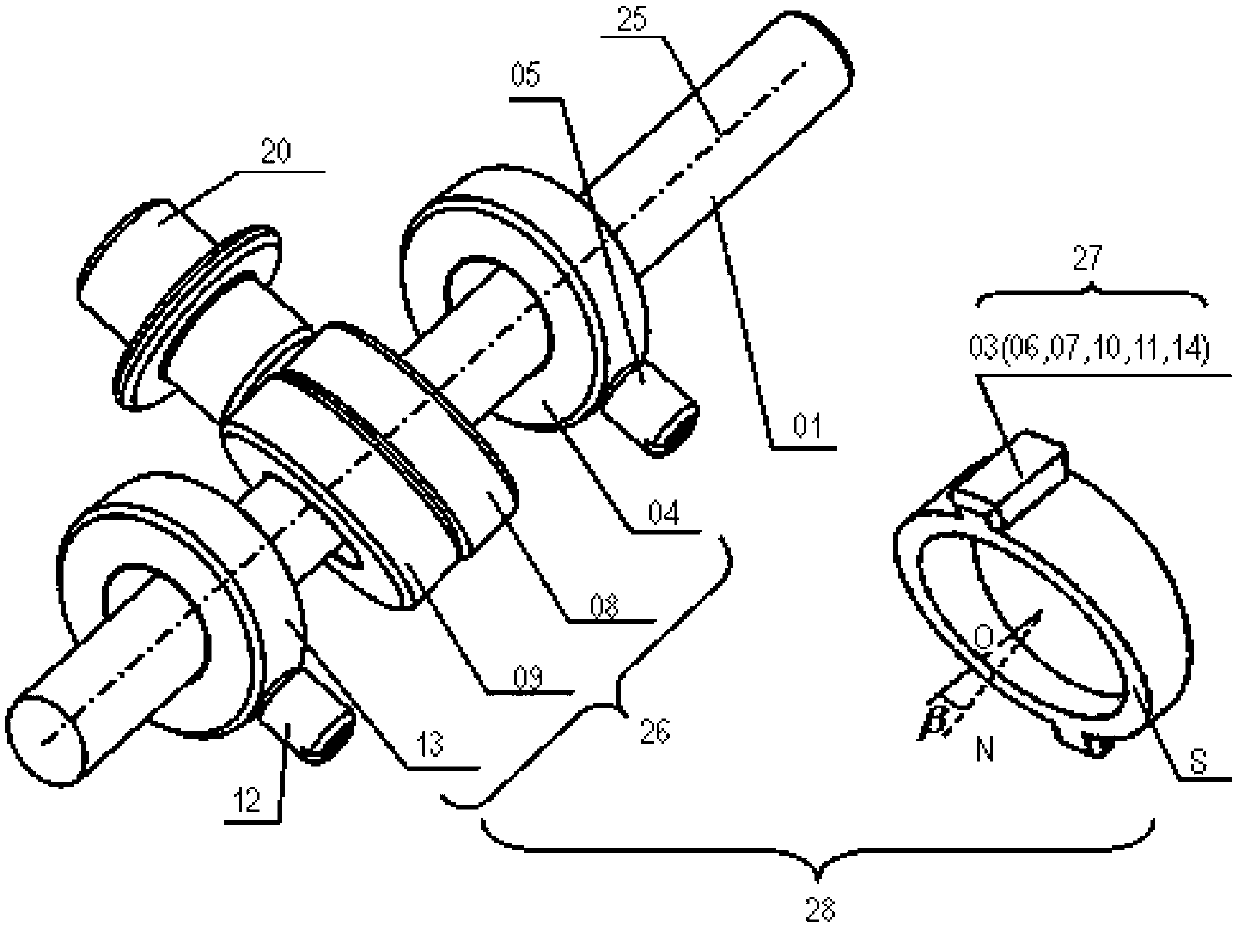

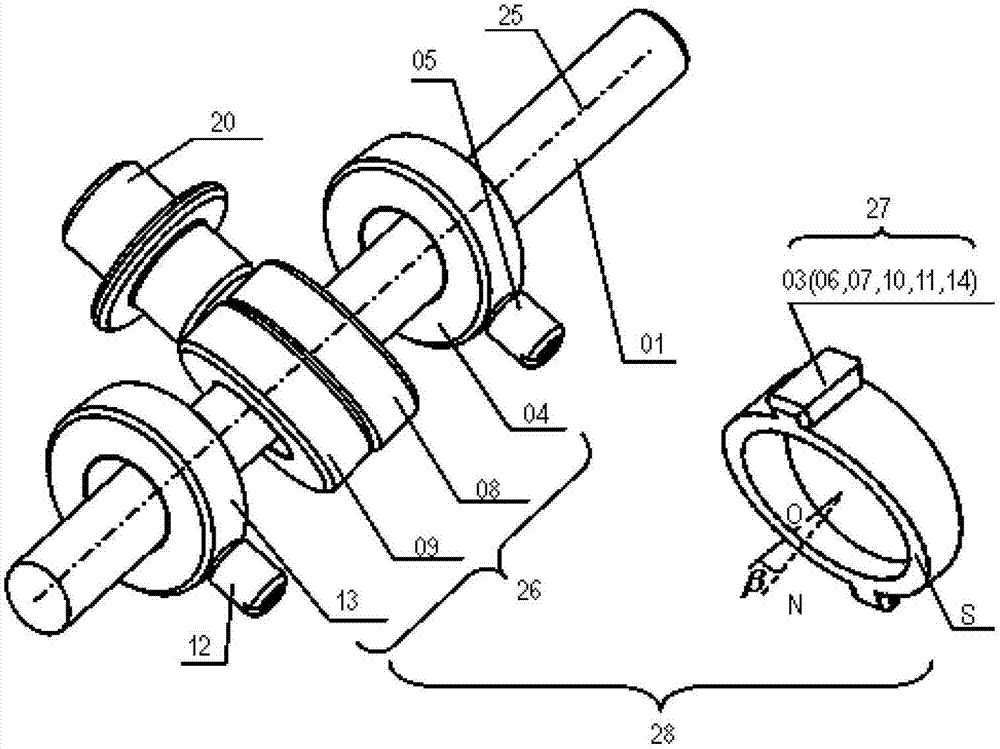

No-tooth transmission lead screw with adjustable polish rod axis positions and transmission friction force

The invention discloses a no-tooth transmission lead screw with adjustable polish rod axis positions and transmission friction force. The no-tooth transmission lead screw with the adjustable polish rod axis positions and the transmission friction force comprises a displacement block, a displacement platform, a polish rod, a friction drive pair, an adjusting screw group and a jacking bolt group, wherein the displacement platform is connected with the displacement block, the polish rod penetrates through an inner cavity of the displacement block, the friction drive pair is installed on the polish rod and is composed of a bearing group and a wedge block group, the adjusting screw group is pushed upwards to the bearing group and used for adjusting the positions of a polish rod axis, and the jacking bolt group is used for adjusting the friction force, locking and loosening the drive pair. Fast centering of the polish rod is easily achieved, and motion stability is good by adjusting of the adjusting screw group. By means of adjusting of the jacking bolt group, the transmission friction force can be adjusted, locking and releasing of the polish rod can be achieved, the displacement platform is enabled to do precise fine motions and fast motions, and changing over of the motions is simple, convenient and fast. The no-tooth lead screw is small in abrasion, strong in loading capacity, easy to machine, convenient to assemble, stable in quality and low in cost by adopting of symmetric design and standard parts. The no-tooth lead screw can be applied to a machine tool, a coordinate measuring machine and an image measurement device to drive the displacement platform to do fine displacement motions.

Owner:HEFEI MIKE PHOTOELECTRIC TECH

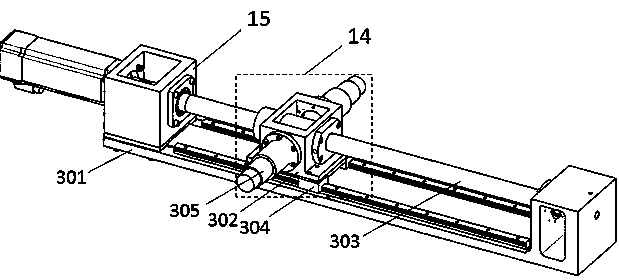

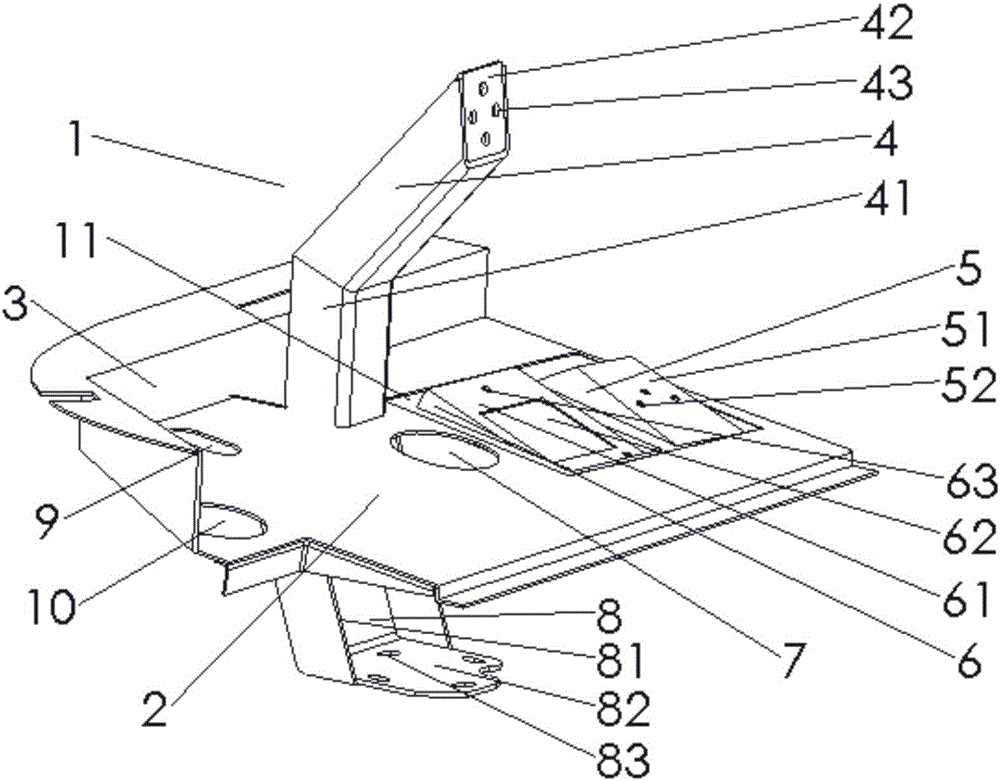

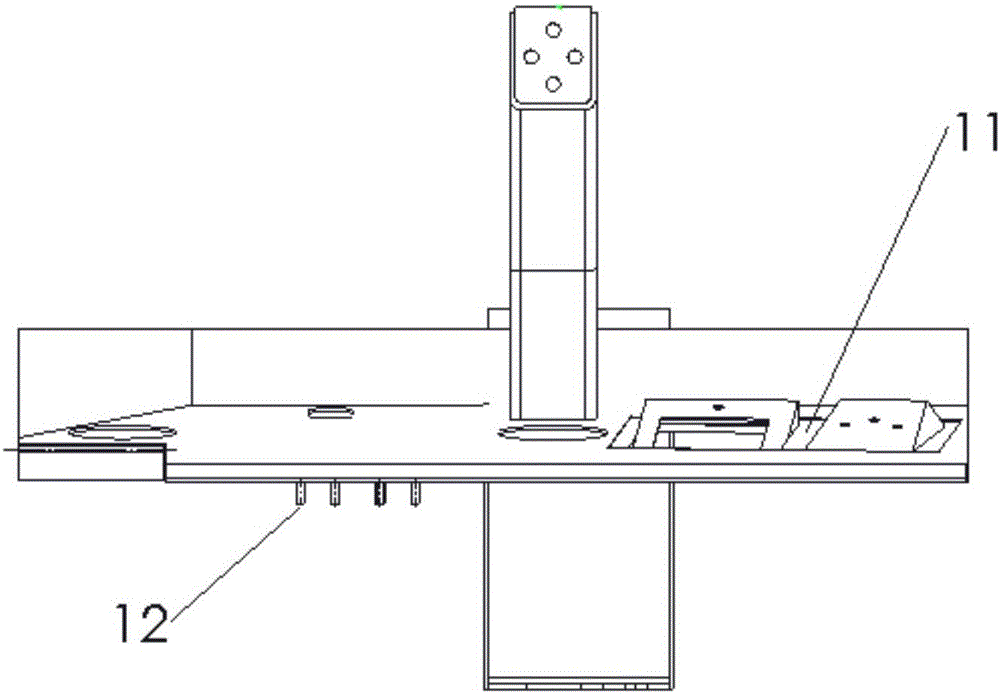

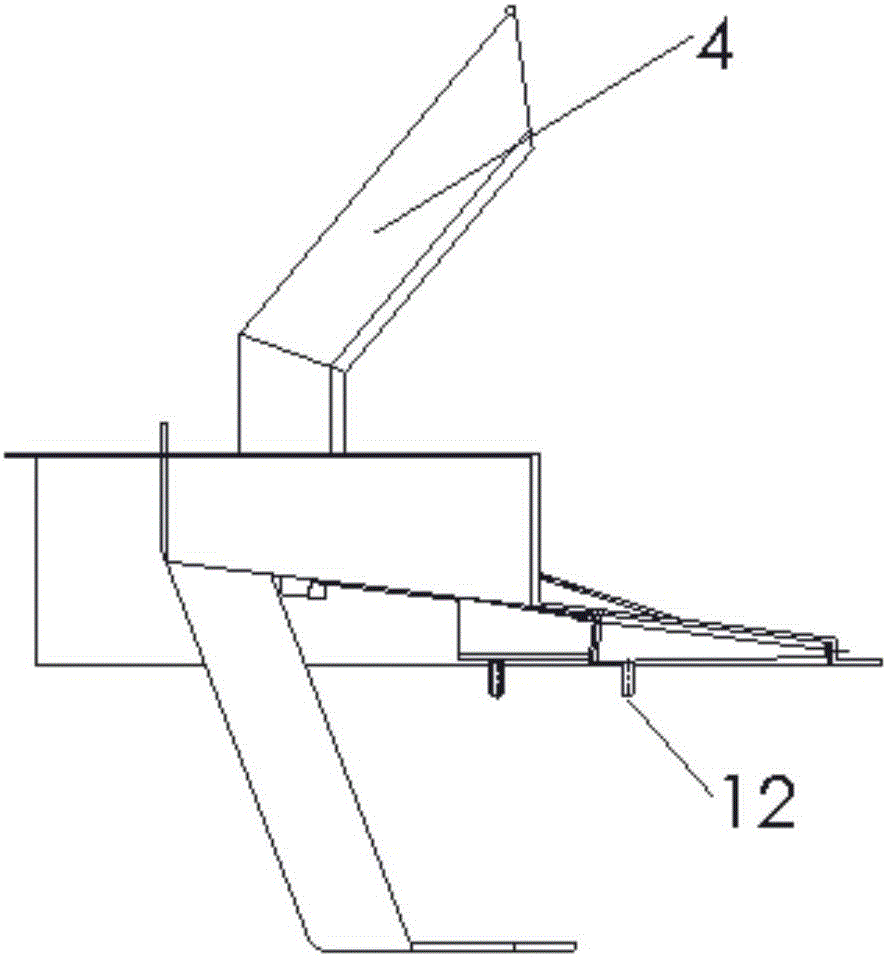

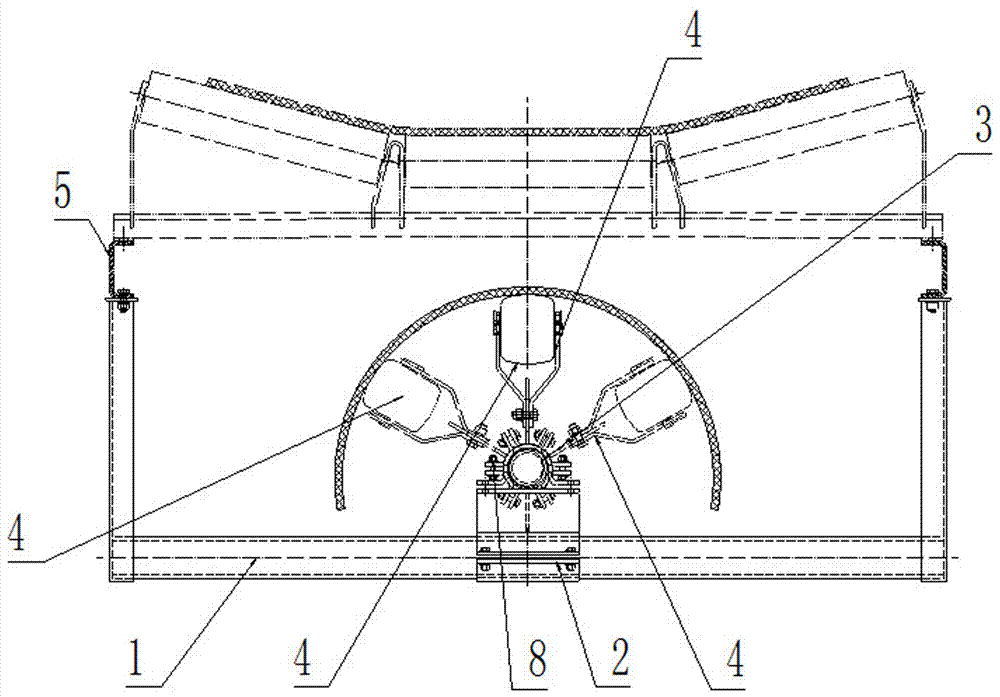

Model test strain brick sensor processing table and operation method thereof

ActiveCN108917586AAdaptableEven by forceElectrical/magnetic solid deformation measurementBrickEngineering

The invention discloses a model test strain brick sensor processing table and an operation method thereof. The model test strain brick sensor processing table comprises a stabilization system, a rotating clamping system and a flat cable fixing system, wherein the stabilization system comprises a base, a rotating disc locking key and angle scribed lines; the rotating disc locking key and the anglescribed lines are arranged on the base, so that a rotating angle of the rotating disc can be controlled and quantified; the rotating clamping system comprises a rotating disc, a sliding rail, a clamping plate, a clamping plate locking key, a clamping plate gasket and a ruler, wherein the sliding rail for the clamping plate to move is arranged on the rotating disc; the clamping plate locking key and the ruler can control the sliding rail to move, and strain bricks with different sizes can be clamped; the flat cable fixing system comprises a universal ball, a rotating arm and a flat cable clamp;the universal ball is connected to the rotating arm, and a flat cable can be clamped and fixed at any angle, so that flat cable welding can be facilitated. According to the model test strain brick sensor processing table and the operation method thereof, a welding angle of the strain brick is adjusted through the rotating disc, and the strain brick is fixed by the clamping plate and the clampingplate gasket; and furthermore, the model test strain brick sensor processing table and the operation method thereof have the advantages of being uniform in force transmission and adjustable in size, the working efficiency is improved, and the yield of a strain brick sensor is guaranteed.

Owner:SHANDONG UNIV OF SCI & TECH

Low-noise automobile trunk reducer

ActiveCN105041986ASimple internal structureImprove running accuracy and sealing performanceGear vibration/noise dampingToothed gearingsGear transmissionCarrying capacity

The invention relates to the technical field of reducers, and provides a low-noise automobile trunk reducer which comprises an inner gear shell, an input mechanism and at least two stages of planetary gear transmission mechanisms. The inner gear shell comprises an inner gear shell body and first helical teeth integrally formed on the inner wall of the inner gear shell body. A first-stage planet holder in the first-stage planetary gear transmission mechanism is integrally formed. The input mechanism comprises a first-stage sun gear. The first-stage sun gear, first-stage planetary gears, a second-stage sun gear and second-stage planetary gears are in helical tooth transmission with the inner gear shell body. In the low-noise automobile trunk reducer, the helical tooth structure and the inner gear shell body are integrally formed, and manufacturing errors caused by respective machining of the helical teeth are avoided; meanwhile, the first-stage planet holder is of an integral structure, so that the overall running precision and sealing performance of the reducer are improved, and assembling errors caused by combined assembling are avoided; all transmission gears are in helical tooth transmission, so that the overlap ratio is high, running is stable, and carrying capacity is large; and the reducer is more compact in structure and smaller in size.

Owner:SHENZHEN ZHAOWEI MACHINERY&ELECTRONICS CO LTD

Low noise car tail box reducer

ActiveCN105041986BSimple internal structureHigh running precisionGear vibration/noise dampingToothed gearingsLow noiseReducer

The invention relates to the technical field of reducers, and provides a low-noise automobile trunk reducer which comprises an inner gear shell, an input mechanism and at least two stages of planetary gear transmission mechanisms. The inner gear shell comprises an inner gear shell body and first helical teeth integrally formed on the inner wall of the inner gear shell body. A first-stage planet holder in the first-stage planetary gear transmission mechanism is integrally formed. The input mechanism comprises a first-stage sun gear. The first-stage sun gear, first-stage planetary gears, a second-stage sun gear and second-stage planetary gears are in helical tooth transmission with the inner gear shell body. In the low-noise automobile trunk reducer, the helical tooth structure and the inner gear shell body are integrally formed, and manufacturing errors caused by respective machining of the helical teeth are avoided; meanwhile, the first-stage planet holder is of an integral structure, so that the overall running precision and sealing performance of the reducer are improved, and assembling errors caused by combined assembling are avoided; all transmission gears are in helical tooth transmission, so that the overlap ratio is high, running is stable, and carrying capacity is large; and the reducer is more compact in structure and smaller in size.

Owner:SHENZHEN ZHAOWEI MACHINERY&ELECTRONICS CO LTD

Vehicle lamp optical element, vehicle lamp module and vehicle

PendingCN112781001AHigh degree of integrationLow costVehicle headlampsOptical signallingEngineeringOptics

Owner:HASCO VISION TECHNOLOGY CO LTD

Recyclable low-carbon portable building block die

InactiveCN104912250AAvoid manufacturing errorsEasy to fixBuilding componentsConstruction engineeringLintel

The invention discloses a recyclable low-carbon portable building block die. According to the invention, a building block manufacturing die is standardized and can flexibly move and can be used in a factory or worksite. A die chassis is used as a carrier, can be suitable for storey height according to wall design and is composed of one or two pieces of originally-sized plywood or OSB. A load-bearing frame structured keel below the chassis adopts standard timber, and has consistent size with a building block stud or keel, and reacting force produced by nailing or screw-driving can be absorbed. A movable SIMPSON angle iron-shaped A34 or Z4 right-angle connecting piece can be installed on the surface of the chassis; one end is fixed to the plywood or OSB through screws; and a pair of connecting pieces forms a groove for containing the stud. Through the systematic management and regulation, stipulation and control and calibration of the stud, column and lintel positions, the die chassis can be lifted and put on a stand or turnplate and is ergonomic to minimize occupational injuries, fault waste or rework and raise efficiency and accuracy. Measurement is not required, block production man-hour is shortened and space usage is reduced.

Owner:聂小勤

A toothless drive screw with adjustable shaft axis position and drive friction

The invention discloses a no-tooth transmission lead screw with adjustable polish rod axis positions and transmission friction force. The no-tooth transmission lead screw with the adjustable polish rod axis positions and the transmission friction force comprises a displacement block, a displacement platform, a polish rod, a friction drive pair, an adjusting screw group and a jacking bolt group, wherein the displacement platform is connected with the displacement block, the polish rod penetrates through an inner cavity of the displacement block, the friction drive pair is installed on the polish rod and is composed of a bearing group and a wedge block group, the adjusting screw group is pushed upwards to the bearing group and used for adjusting the positions of a polish rod axis, and the jacking bolt group is used for adjusting the friction force, locking and loosening the drive pair. Fast centering of the polish rod is easily achieved, and motion stability is good by adjusting of the adjusting screw group. By means of adjusting of the jacking bolt group, the transmission friction force can be adjusted, locking and releasing of the polish rod can be achieved, the displacement platform is enabled to do precise fine motions and fast motions, and changing over of the motions is simple, convenient and fast. The no-tooth lead screw is small in abrasion, strong in loading capacity, easy to machine, convenient to assemble, stable in quality and low in cost by adopting of symmetric design and standard parts. The no-tooth lead screw can be applied to a machine tool, a coordinate measuring machine and an image measurement device to drive the displacement platform to do fine displacement motions.

Owner:HEFEI MIKE PHOTOELECTRIC TECH

Ultrahigh-speed shuttleless narrow loom

The invention relates to the technical field of weaving, in particular to an ultrahigh-speed shuttleless narrow loom, and solves the problems of an incomplete part structure, large assembly and maintenance amount, low weaving accuracy and a low weaving speed of the conventional ribbon loom. The loom comprises a frame, a driving device arranged in the frame, and a weaving mechanism, wherein the weaving mechanism comprises a weft insertion mechanism, a heald frame mechanism, a pattern chain and a rocker arm; the weft insertion mechanism has an integral base split clamping structure; a tensioning pressure seam is arranged at a position where a weft insertion bearing is arranged and positioned; the two ends of an inner ring of the weft insertion bearing stretch out of an outer ring to be manufactured into a weft insertion small shaft; the heald frame mechanism is provided with a bearing seat frame and a clamping transverse heald frame which are vertically sleeved with each other; the bearing seat frame is provided with a plurality of linear bearings which correspond to one another coaxially up and down; an elastic steel wire heald with a heald eye is arranged in the clamping transverse heald frame; and the pattern chain is formed by connecting a double high pattern sheet, high and low chain sheets and a double low pattern sheet through tenon sheets and notches. The ultrahigh-speed shuttleless narrow loom has high weaving accuracy and a high weaving speed and is convenient to assemble and maintain.

Owner:来永泰

Steering bracket assembly

InactiveCN106585729AReduce in quantityEasy to operateSuperstructure subunitsSteering columnsBogieSteering column

The invention discloses a steering bracket assembly. The steering bracket assembly comprises a support plate, a steering tube column connecting component, a mounting region, an angle bogie mounting bracket, a clutch pedal mounting hole and a hanging device, wherein the steering tube column connecting component is arranged on the upper side of the middle part of the support plate; the mounting region is arranged at the middle part of the right side of the support plate, and an accelerator pedal mounting component and a brake pedal mounting component are arranged on the mounting region; the angle bogie mounting bracket is arranged at the lower end of the right lower side of the support plate; the clutch pedal mounting hole is formed in the left side of the steering tube column connecting component; and the hanging device is used for hanging a clutch control mechanism.

Owner:BEIJING NORTH HUADE NEOPLAN BUS

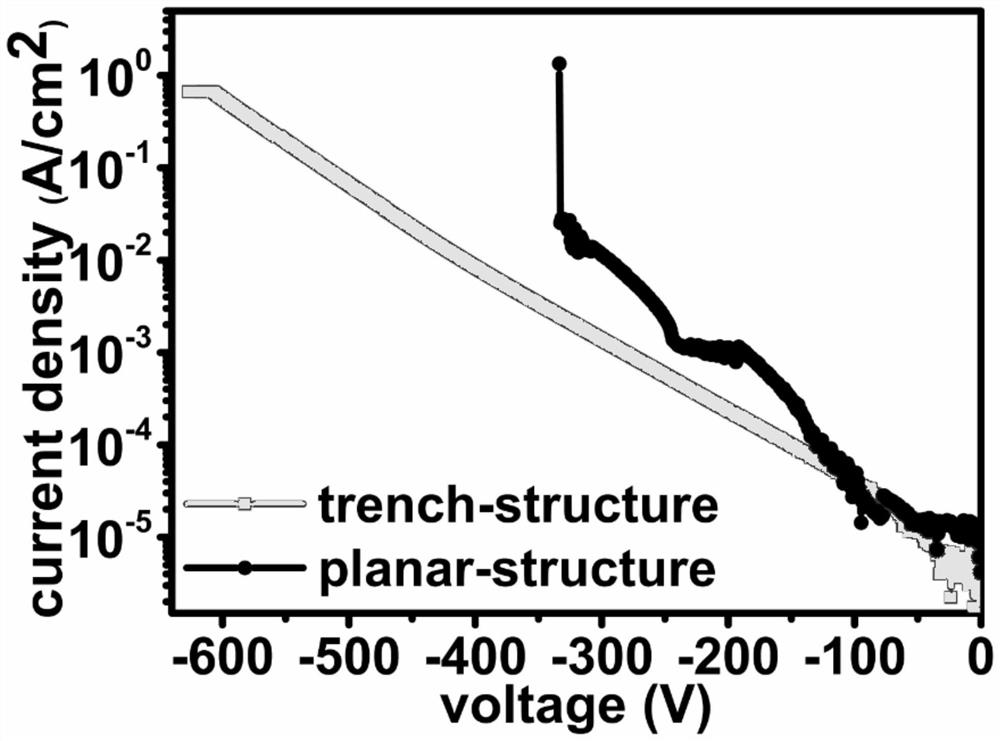

Method for improving electrical performance of GaN vertical Schottky diode with strip-shaped groove structure based on self-alignment process

PendingCN113380610AImprove the withstand voltage levelReduce the effect of electric field concentrationSemiconductor/solid-state device manufacturingDiodeSemiconductor structureInductively coupled plasma

The invention discloses a method for improving the electrical performance of a GaN vertical Schottky diode with a strip-shaped groove structure based on a self-alignment process. The method comprises the following steps: preparing a photoresist etching mask on the front surface of a self-supporting substrate GaN by adopting a standard photoetching process, performing an alignment mark etching experiment on the self-supporting substrate GaN by adopting an inductively coupled plasma (ICP) dry etching process, carrying out vacuum evaporating of a Ti / Al / Ni / Au metal layer on the back surface of the self-supporting GaN substrate by adopting an electron beam process, and carrying out rapid annealing treatment to form ohmic contact, preparing a strip-shaped metal Ni mask on the front surface of the self-supporting GaN substrate by adopting photoetching and electron beam processes, etching the strip-shaped metal Ni mask by adopting an ICP (Inductively Coupled Plasma) dry etching process, and injecting Ar ions into the front surface of the self-supporting substrate GaN, and finally, preparing a Ni / Al composite metal layer on the front surface of the self-supporting GaN substrate after ion implantation to form the GaN Schottky diode with a metal-insulating layer-semiconductor structure. According to the invention, the reverse electric leakage of a common vertical GaN Schottky diode can be effectively reduced, and the breakdown voltage is improved.

Owner:XI AN JIAOTONG UNIV

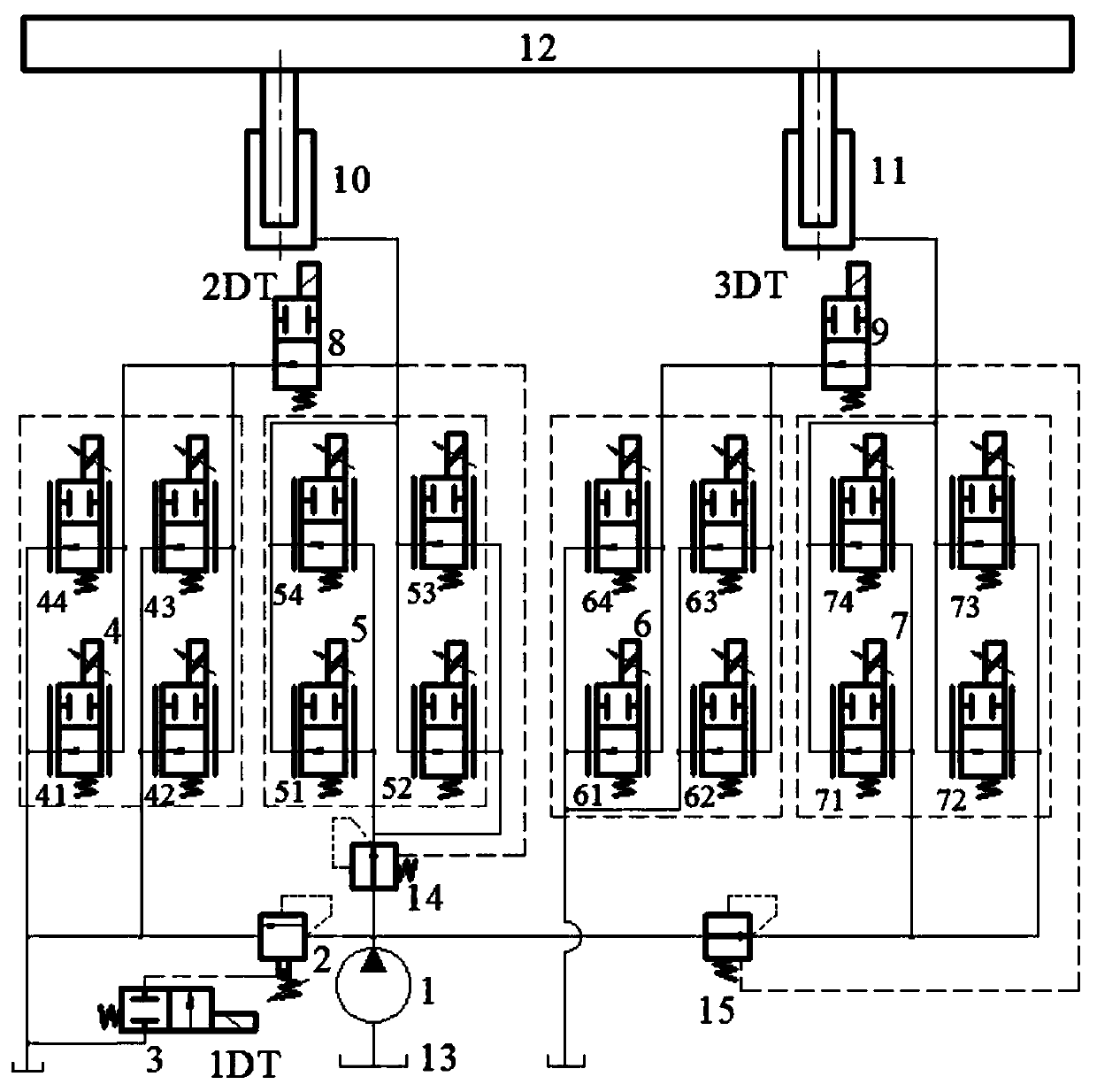

Plunger type leveling hydraulic system with movable beam of large hydraulic machine

ActiveCN111156211AAvoid equipment height that is too highPrecise flow controlServomotor componentsServomotorsFlux controlElectromagnetic valve

The invention discloses a plunger type leveling hydraulic system with a movable beam of a large hydraulic machine, and relates to the field of large hydraulic machines. The plunger type leveling hydraulic system with the movable beam of the large hydraulic machine comprises the movable beam, first leveling plunger cylinders, second leveling plunger cylinders, a first two-position two-way electromagnetic valve, a second two-position two-way electromagnetic valve, a third two-position two-way electromagnetic valve, a first two-position two-way plug-in proportional valve terminal, a second two-position two-way plug-in proportional valve terminal, a third two-position two-way plug-in proportional valve terminal, a fourth two-position two-way plug-in proportional valve terminal, a proportionalrelief valve and a hydraulic pump. The diagonal vertexes of the movable beam are provided with the four leveling plunger cylinders: the first leveling plunger cylinders and the second leveling plungercylinders. According to the plunger type leveling hydraulic system with the movable beam of the large hydraulic machine, the stroke of the plunger cylinders is twice of the length of the cylinders, the height of equipment is prevented from being too large, and the system has the advantages of being small in size, low in pressure loss and precise in flow control.

Owner:JIANGSU UNIV OF TECH

A wafer-level fan-out stack packaging process method

ActiveCN107481945BReduce thicknessSimple processSolid-state devicesSemiconductor/solid-state device manufacturingManufacturing technologyInjection moulding

A wafer-level fan-out stack packaging process method, comprising the steps of: attaching a layer of dry photoresist film on the high-temperature bonding adhesive layer on the light-transmitting temporary substrate; forming a dry photoresist film on the dry photoresist film A plurality of blind holes directly through the high-temperature bonding adhesive layer; after the dry photoresist film is cured, implant conductive metal posts in the blind holes; mount bare chips on the surface of the dry photoresist film; the overall Injection molding and grinding the surface of the plastic package until the pads of the bare chip are completely exposed; making a rewiring layer on the grinding surface of the plastic package for connecting the conductive metal post and the bare chip, so The rewiring layer is provided with micro-bumps obtained by ball planting and reflow soldering; the light-transmitting temporary substrate and the high-temperature bonding adhesive layer are removed to obtain a packaging unit; a fan-out stacked packaging structure is obtained according to the packaging unit. The invention simplifies the manufacturing process of the fan-out stacked packaging and reduces the manufacturing cost of the stacked packaging.

Owner:NAT CENT FOR ADVANCED PACKAGING

A model test strain brick sensor processing platform and its operation method

ActiveCN108917586BAdaptableEven by forceElectrical/magnetic solid deformation measurementModel testRotating disc

The invention discloses a model test strain brick sensor processing table and an operation method thereof. The model test strain brick sensor processing table comprises a stabilization system, a rotating clamping system and a flat cable fixing system, wherein the stabilization system comprises a base, a rotating disc locking key and angle scribed lines; the rotating disc locking key and the anglescribed lines are arranged on the base, so that a rotating angle of the rotating disc can be controlled and quantified; the rotating clamping system comprises a rotating disc, a sliding rail, a clamping plate, a clamping plate locking key, a clamping plate gasket and a ruler, wherein the sliding rail for the clamping plate to move is arranged on the rotating disc; the clamping plate locking key and the ruler can control the sliding rail to move, and strain bricks with different sizes can be clamped; the flat cable fixing system comprises a universal ball, a rotating arm and a flat cable clamp;the universal ball is connected to the rotating arm, and a flat cable can be clamped and fixed at any angle, so that flat cable welding can be facilitated. According to the model test strain brick sensor processing table and the operation method thereof, a welding angle of the strain brick is adjusted through the rotating disc, and the strain brick is fixed by the clamping plate and the clampingplate gasket; and furthermore, the model test strain brick sensor processing table and the operation method thereof have the advantages of being uniform in force transmission and adjustable in size, the working efficiency is improved, and the yield of a strain brick sensor is guaranteed.

Owner:SHANDONG UNIV OF SCI & TECH

Specimen and experimental method for measuring shear modulus of flexible skin of morphing aircraft

ActiveCN110686972BImprove stabilityEnsure consistencyMaterial strength using tensile/compressive forcesMaterial strength using steady shearing forcesShear modulusExperimental methods

The invention discloses a sample for measuring the shear modulus of a flexible skin of a variant aircraft and an experimental method, and relates to the technical field of structural mechanical performance testing. A topology optimized structure and a clamping structure are integrally formed through a 3D printing technology, unavoidable preparation errors produced by manual preparing samples are avoided, good sample stability is ensured, the consistency of a load transfer path is ensured, and the consistency of the experiment is further ensured. The clamping structure can effectively convert the tensile load of a testing machine into the shear load on the topology optimized structure, a unit cell shear test is realized, good experimental results are obtained, and the problem of testing ofshear mechanical properties of a flexible skin structure of the variant aircraft is solved. The installation and disassembly of a fixing structure are simple and easy to operate, and it is ensured that the shear modulus measuring sample of the skin optimized structure does not generate initial deformation during the clamping process, so that the experimental accuracy is further improved.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

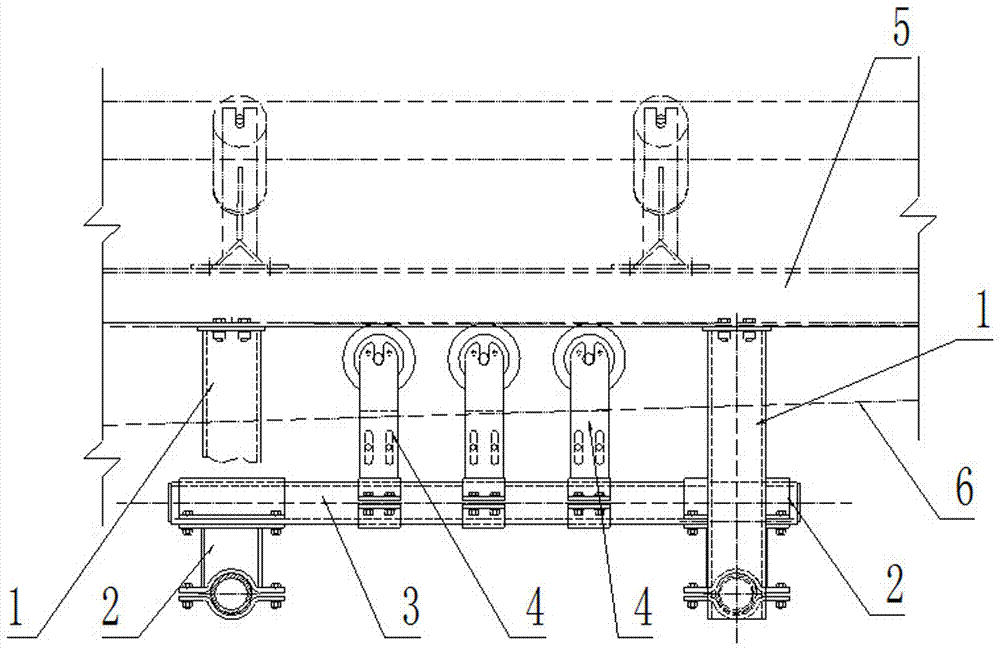

Return trip universal adjustable combined ejector wheel device for round pipe belt conveyor

The invention discloses a return trip universal adjustable combined ejector wheel device for a round pipe belt conveyor. The return trip universal adjustable combined ejector wheel device comprises a machine body longitudinal beam rack, hanging bracket assemblies, adjustable Haff type support assemblies, longitudinal supporting steel pipe guide rods and adjustable ejector wheel assemblies. The two hanging bracket assemblies are of a U-shaped structure and are symmetrically arranged left and right. The two adjustable Haff type support assemblies are arranged and symmetrically arranged on transverse connecting pipes in the left hanging bracket assembly and the right hanging bracket assembly. Each adjustable Haff type support assembly is composed of a transverse adjustable Haff type support, a longitudinal adjustable Haff type support and a connecting block. The three adjustable ejector wheel assemblies are arranged and are completely the same in structure. Each adjustable ejector wheel assembly is composed of a Haff connecting base, an ejector wheel, an ejector wheel installing plate, an ejector wheel connecting plate and an ejector wheel bearing block. According to the technical scheme, the structure is simple, and safety and reliability are achieved; the height, angle, supporting force and transition section shape of a return strip rubber belt in the transition process can be adjusted, and installation and adjustment are convenient; and the phenomenon of rubber belt collapsing and stacking generated in the transition process can be effectively prevented, rubber belt deviating, twisting and tearing defects are overcome, and the service life of the rubber belt is prolonged.

Owner:安徽攀登重工股份有限公司

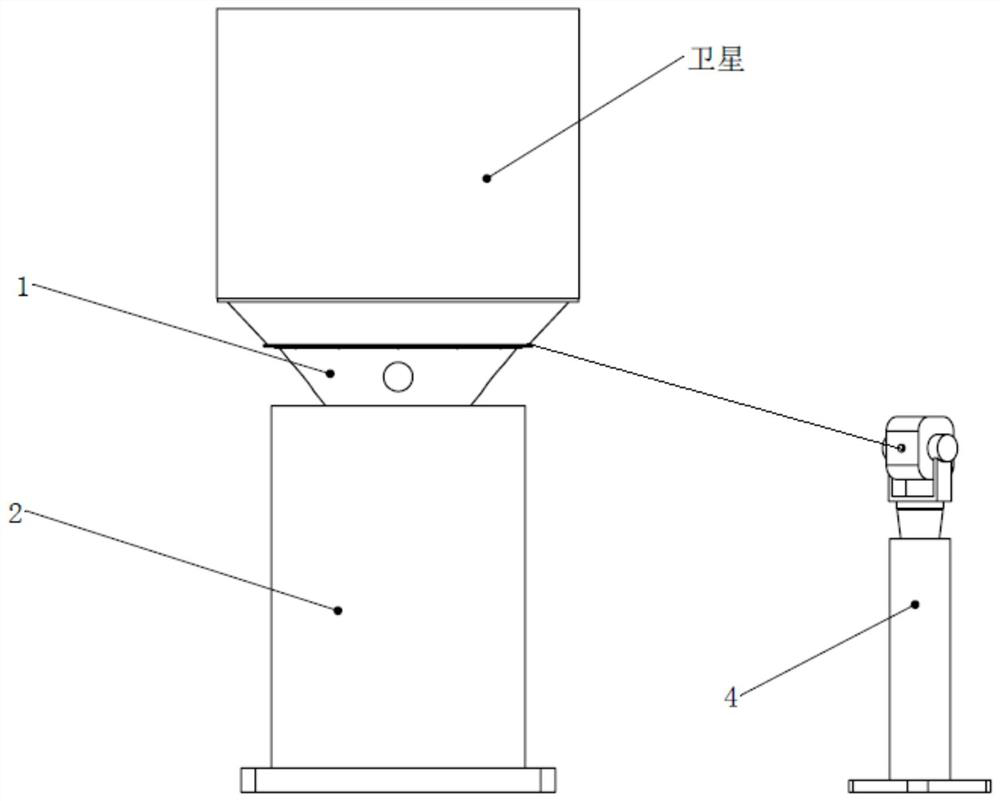

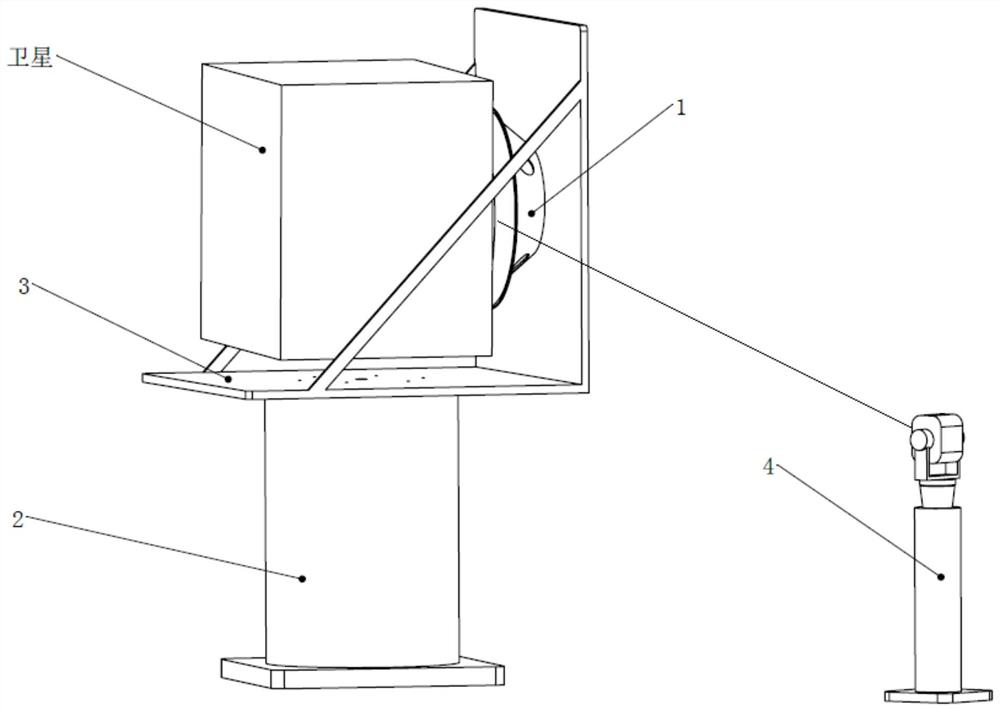

Satellite high-precision centroid measurement method combined with laser tracker

ActiveCN111947834AReduce measurement errorHigh measurement accuracyStatic/dynamic balance measurementComputational physicsSatellite

The invention discloses a satellite high-precision centroid measurement method combined with a laser tracker, and the method comprises the steps: obtaining the centroid position I1 of a combination ofa satellite and a centroid measurement tool in a centroid measurement platform coordinate system in a vertical state of the satellite through the measurement of a centroid measurement platform duringthe measurement of the transverse centroid of the satellite; using the mass center position of the no-load mass measurement tool in the vertical state to obtain the transverse mass center of the satellite through calculation; when satellite longitudinal centroid measurement is carried out, the centroid position I5 of a combination of a satellite and a quality measurement tool in a horizontal state under a quality measurement table coordinate system is obtained through measurement of a quality measurement table, and the satellite longitudinal centroid is obtained through calculation in combination with the centroid position of the no-load quality measurement tool in the horizontal state. By means of the method, the satellite installation error and the tool deformation error are reduced, and the measurement precision of the satellite mass center is remarkably improved.

Owner:AEROSPACE DONGFANGHONG SATELLITE

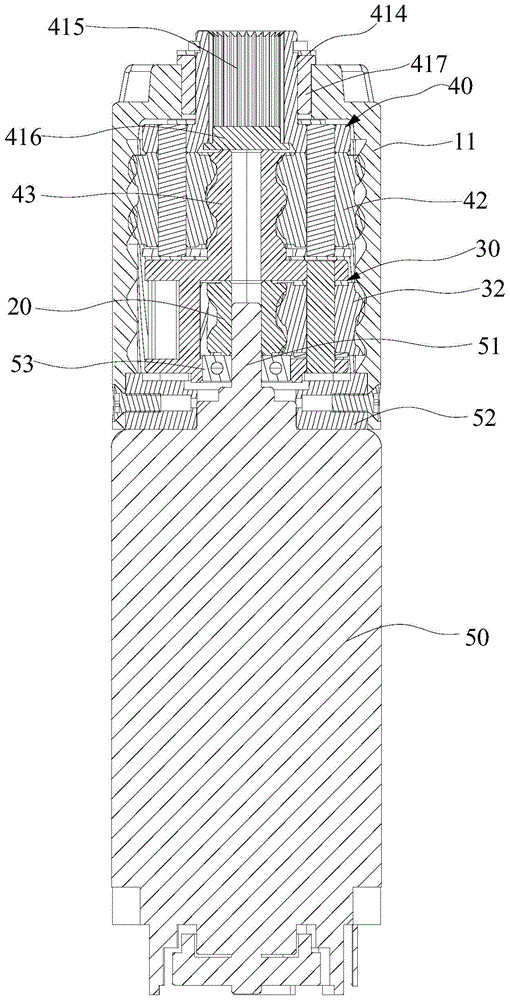

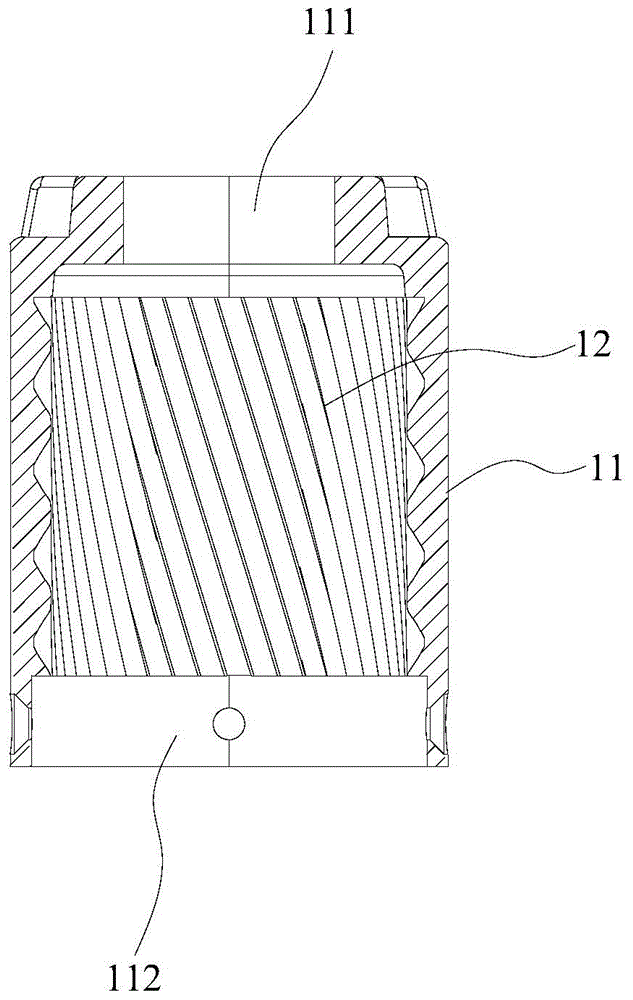

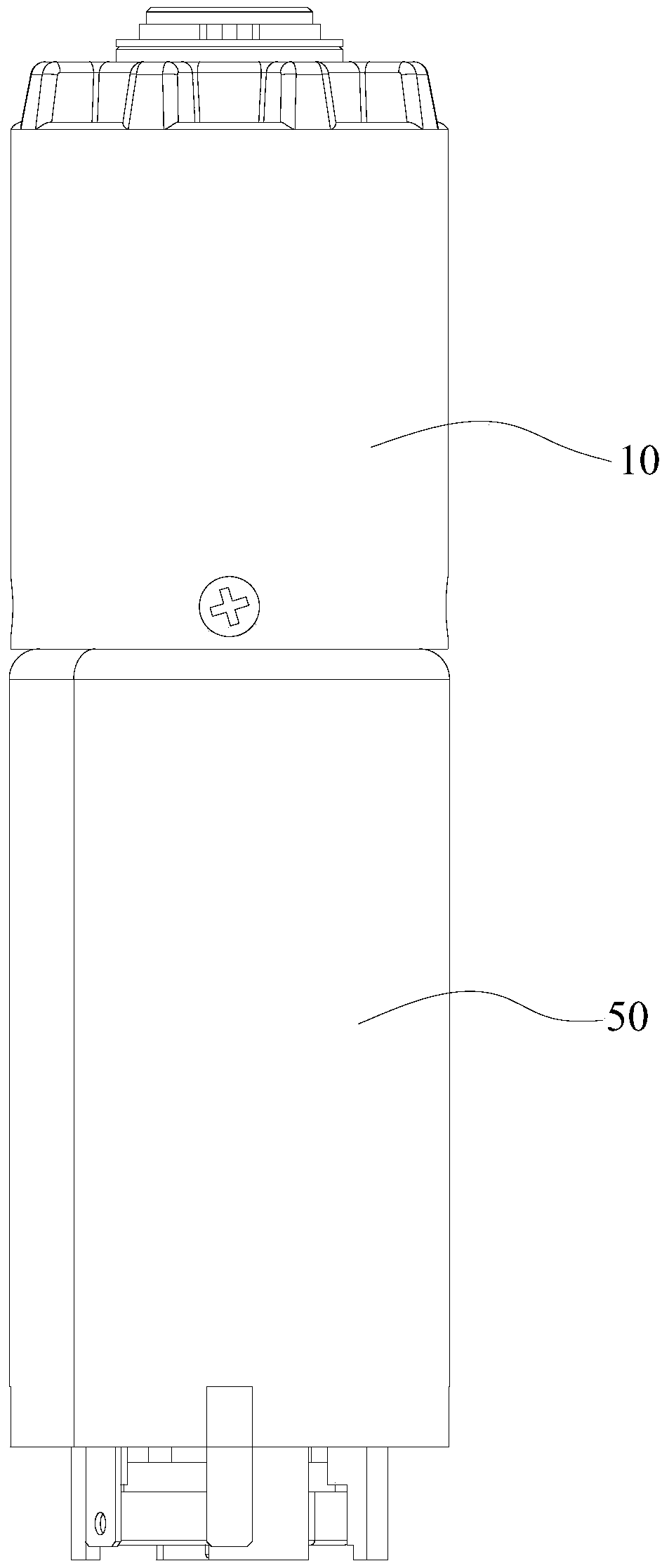

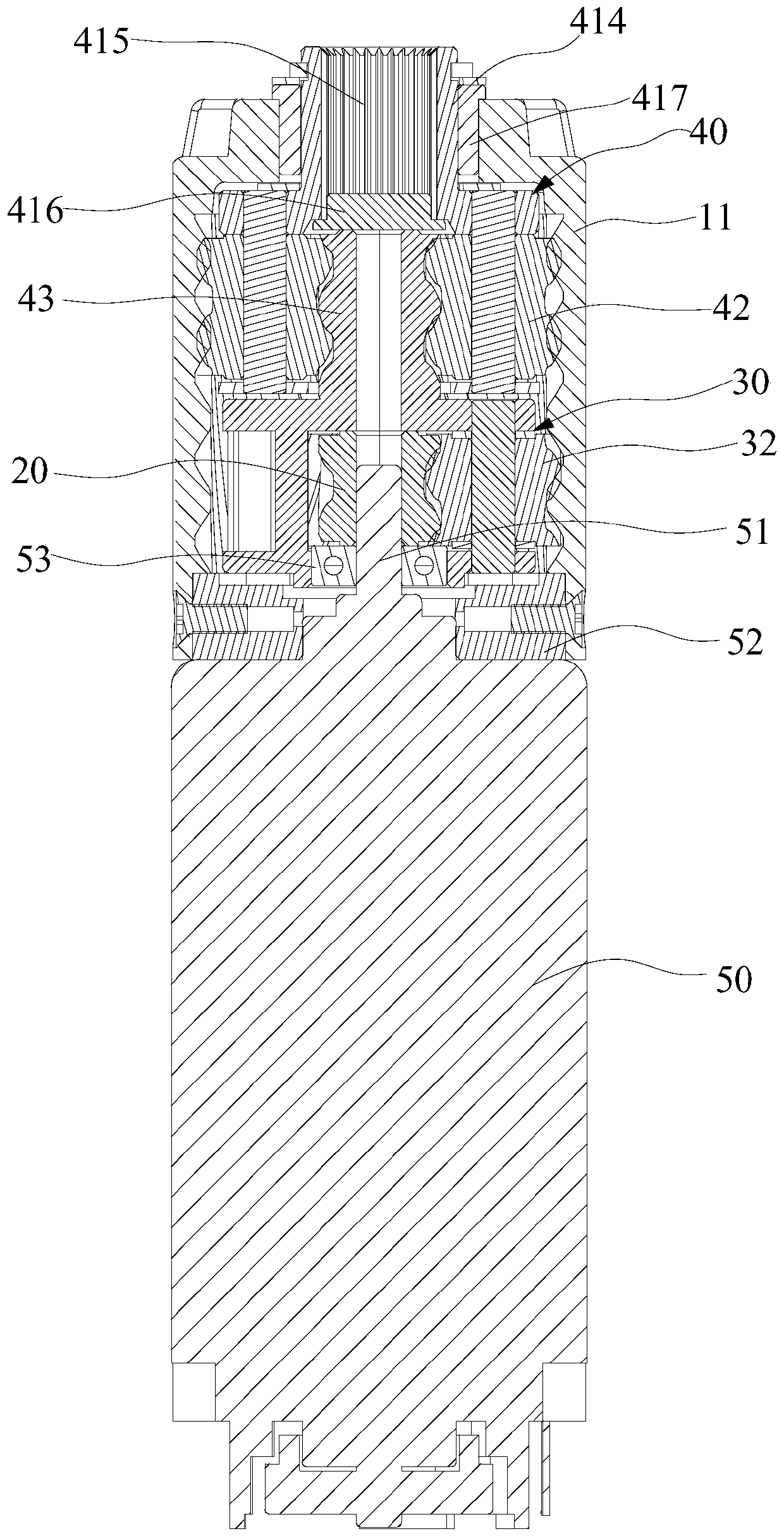

Permanent magnet motor

ActiveCN114123553AConcentricity error is smallImprove running performanceMagnetic circuit stationary partsSupports/enclosures/casingsMagnetoElectrical and Electronics engineering

The invention relates to a permanent magnet motor, which comprises a stator, a rotor and an end cover, and is characterized in that the stator comprises a plurality of unit sheets, the plurality of unit sheets are laminated and fixed by welding, the end cover is fixed on the end surface of the stator, the rotor is connected with a rotating shaft, and the rotating shaft is arranged on the end cover. The motor has the advantages that the concentricity error between the stator and the rotor is greatly reduced, the running performance of the motor is improved, and shaking and movement in the rotating process of the rotating shaft are reduced.

Owner:HANGZHOU NEW HENGLI ELECTRONICS MACHINE MFG

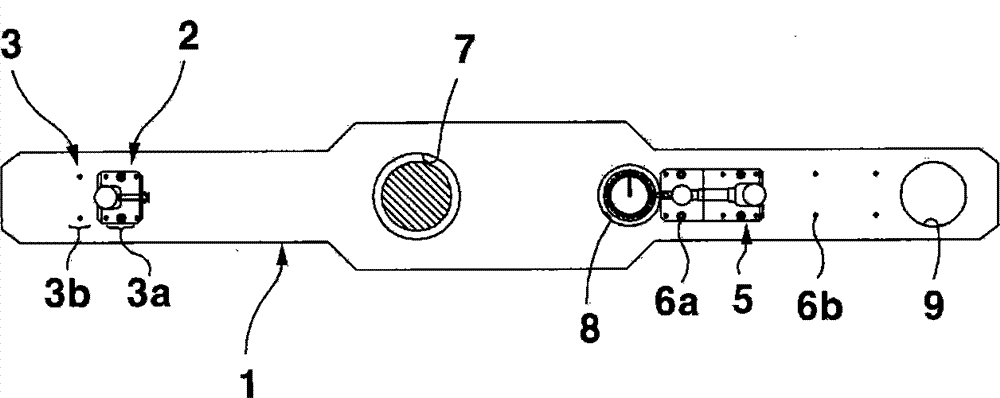

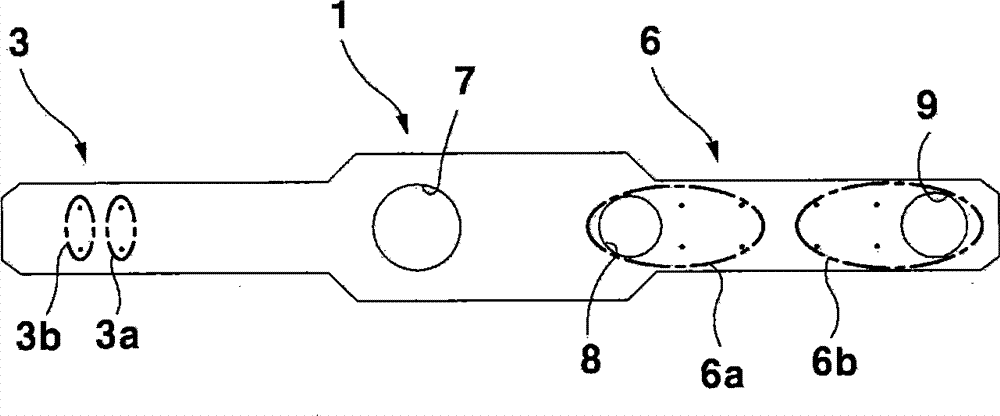

Measuring tool for inner and outer diameter of sealing surface of fuel exchanger

ActiveCN102252579BAvoid manufacturing errorsReduce radiationMechanical diameter measurementsMechanical engineeringEngineering

The invention provides a measuring tool for the inner and outer diameters of the sealing surface of a fuel exchanger, which relates to a tool for measuring the inner and outer diameters of the sealing surface of a fuel exchanger in a heavy water furnace type atomic furnace power plant. According to the measuring tool, one side of a flat strip-shaped main body is equipped with a fixed support part for fixing a support roller assembly. A scale gauge is arranged opposite to the fixed support part and a variable support roller assembly is arranged opposite to the variable support part. Meanwhile, the central part of the fixed support part is equipped with a through hole for a shaft to pass through. An inner diameter measuring hole and an outer diameter measuring hole are respectively arranged close to and apart form the above the through hole. The fixed support part is arranged on one side of the inner diameter setting part and the outer diameter setting part of the main body. The variable support part is arranged on one side of the inner diameter setting part and the outer diameter setting part of the main body.

Owner:韩电KPS株式会社

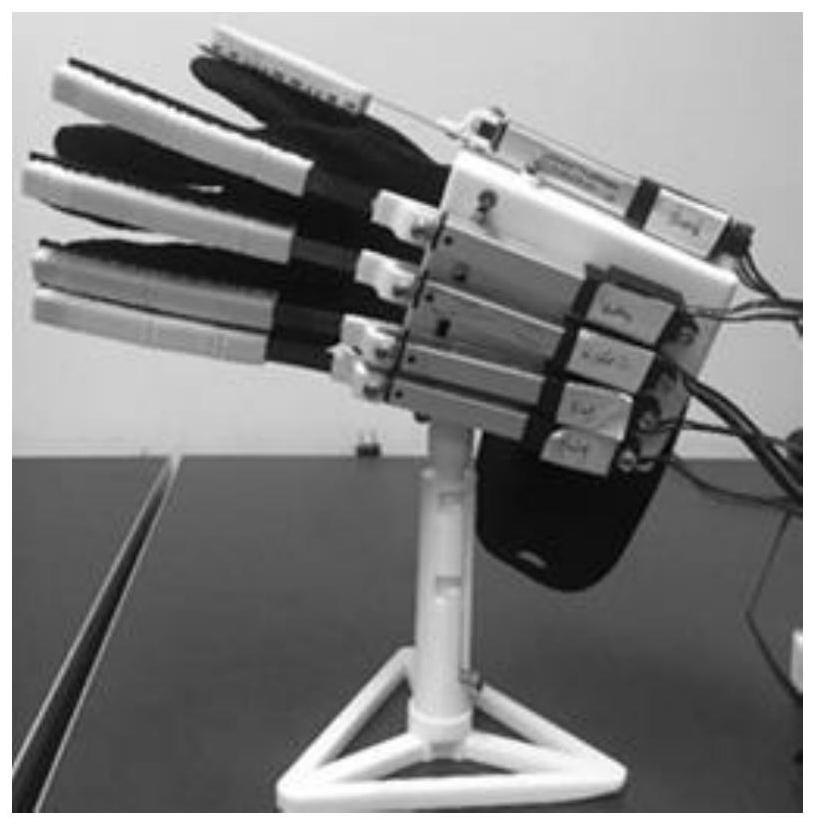

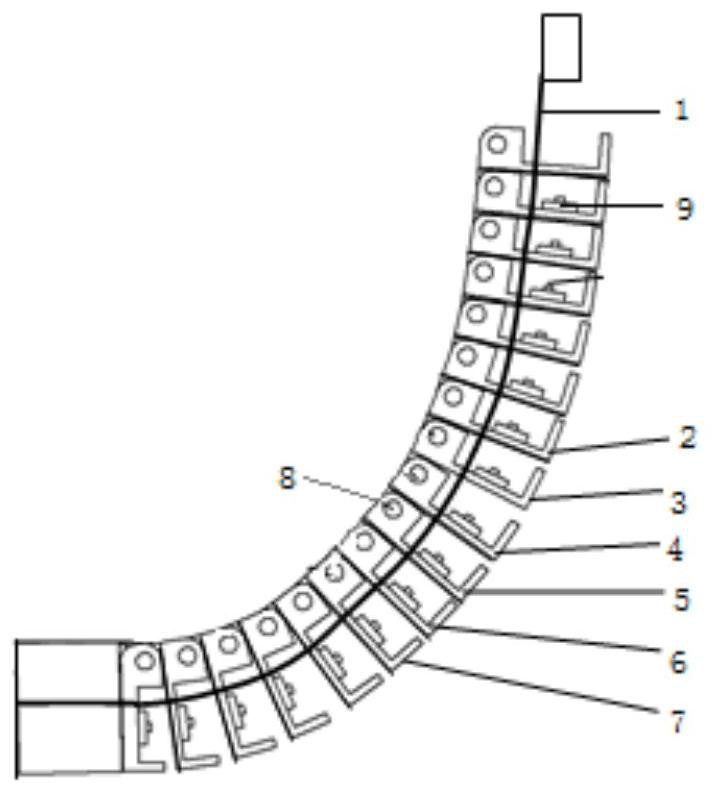

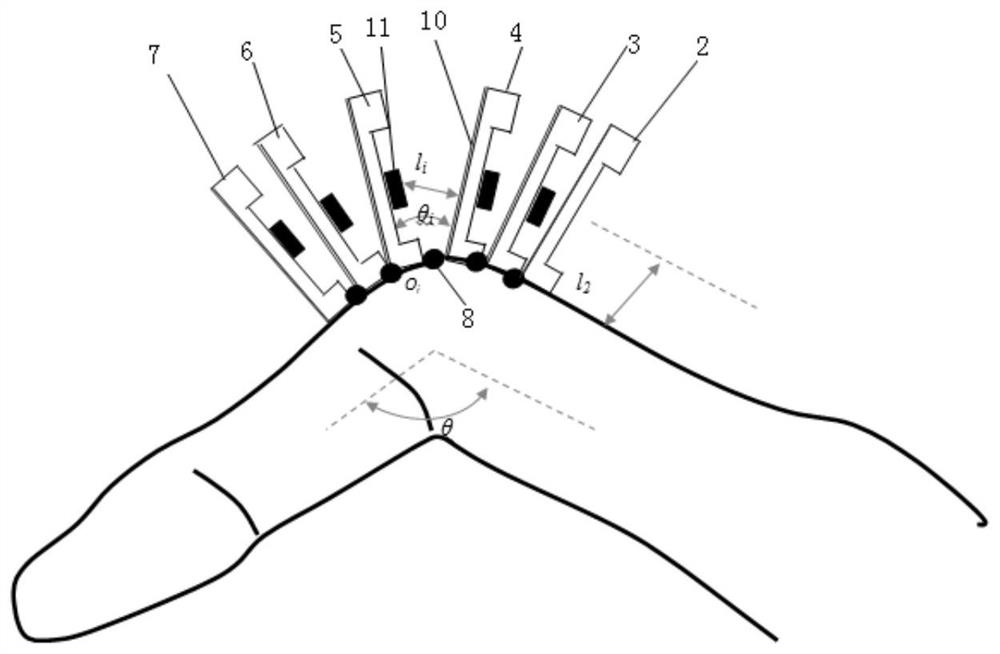

Pose monitoring system and method for multi-section continuum robot

The invention relates to the field of robot pose sensing, in particular to a pose monitoring system and method for a multi-section continuum robot. The system comprises a plurality of photoelectric sensing units, a data acquisition module and a data processing module, each photoelectric sensing unit comprises a light reflecting part and a photoelectric sensitive element which are respectively arranged on opposite surfaces of two adjacent joint operation units of the multi-section continuum robot; the light reflecting parts are used for receiving light emitted by the photoelectric sensitive elements and reflecting the light back to the photoelectric sensitive elements; when the joint operation units rotate, a response electric signal of the photoelectric sensitive elements changes; the data processing module is configured to calculate a relative rotation angle between two adjacent joint operation units where the photoelectric sensing unit corresponding to the data processing module is located by using a preset function according to the response electric signal; and the motion posture of the multi-section continuum robot is determined according to the multiple relative rotation angles. The problem that existing monitoring equipment cannot be installed on a robot with a multi-section continuous structure is solved.

Owner:XI AN JIAOTONG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com