Steel frame with friction energy dissipation self reset device in beam

A technology of frictional energy consumption and self-resetting, which is applied in the field of steel frames, can solve problems such as enlarged frame column spacing, cracking of floor systems, and restricted applications, and achieves low energy consumption costs, reduced economic costs, and controllable damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

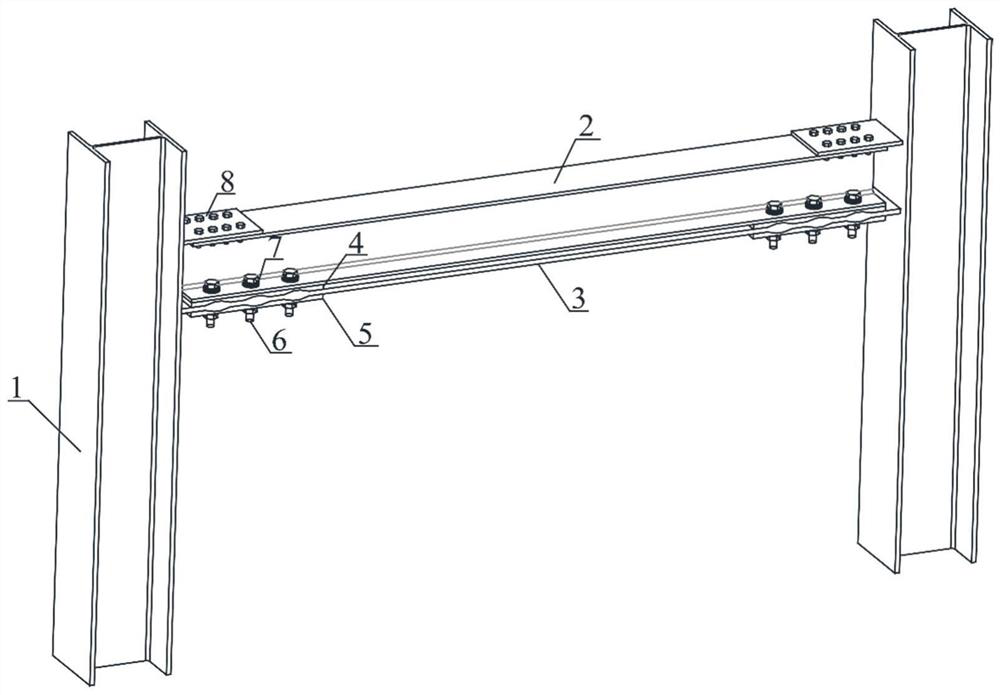

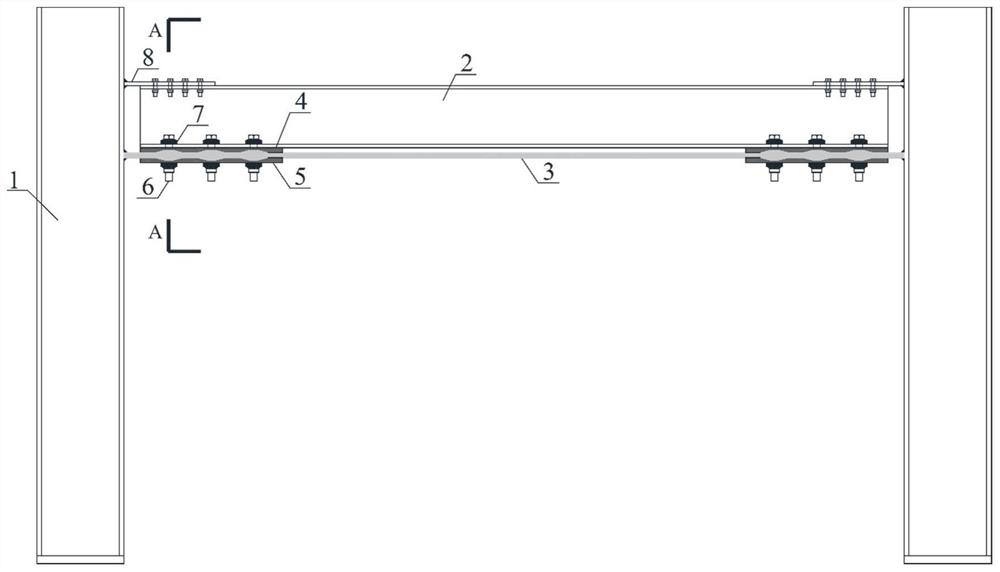

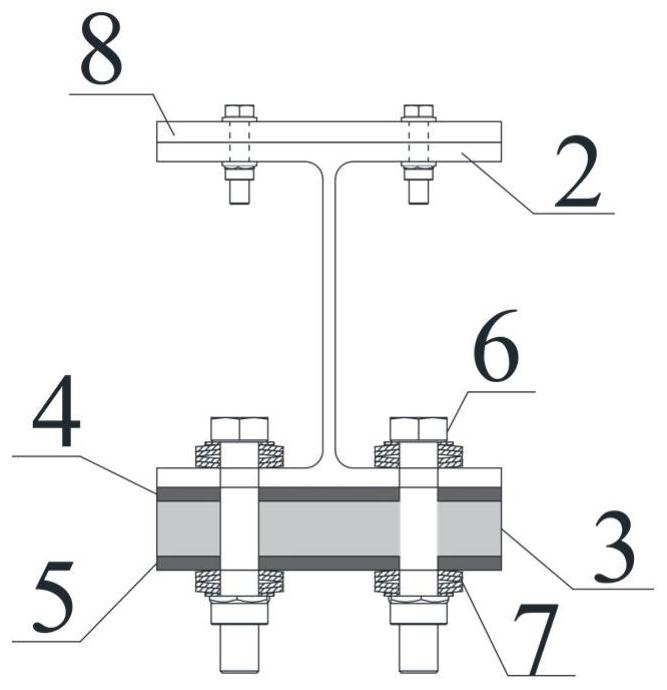

[0026] Such as Figure 1 to Figure 7 As shown, the steel frame in which the frictional energy dissipation self-resetting device is arranged in the beam of the present invention includes at least one structural unit, and the structural unit includes two frame columns 1, an I-shaped steel beam 2, a full-length steel plate 3, and two upper pads Plate 4, two lower backing plates 5, multiple high-strength bolts 6, multiple butterfly gaskets 7 and two flange connecting plates 8, the two ends of the I-beam 2 are connected to the frame column 1 through the flange steel plate 8 Bolt connection, a certain gap is reserved between the I-beam 2 and the frame column 1 so that one side of the flange connecting plate 8 cantilever out of the beam section, the two ends of the long steel plate 3 are welded to the frame column 1, and the backing plate 4 is welded on the outside of the I-shaped steel beam 2, the lower backing plate 5 is located on the lower side of the full-length steel plate 3, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com