Plunger type leveling hydraulic system with movable beam of large hydraulic machine

A technology of hydraulic system and movable beam, which is applied in the driving device, fluid pressure actuating device, mechanical equipment and other directions of forging presses, which can solve the problem of throttling loss, large decompression loss of speed control valve, affecting the life of press equipment and workpiece material. Non-uniformity and other problems, to achieve the effect of small pressure loss, avoiding high equipment height, and preventing insufficient filling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

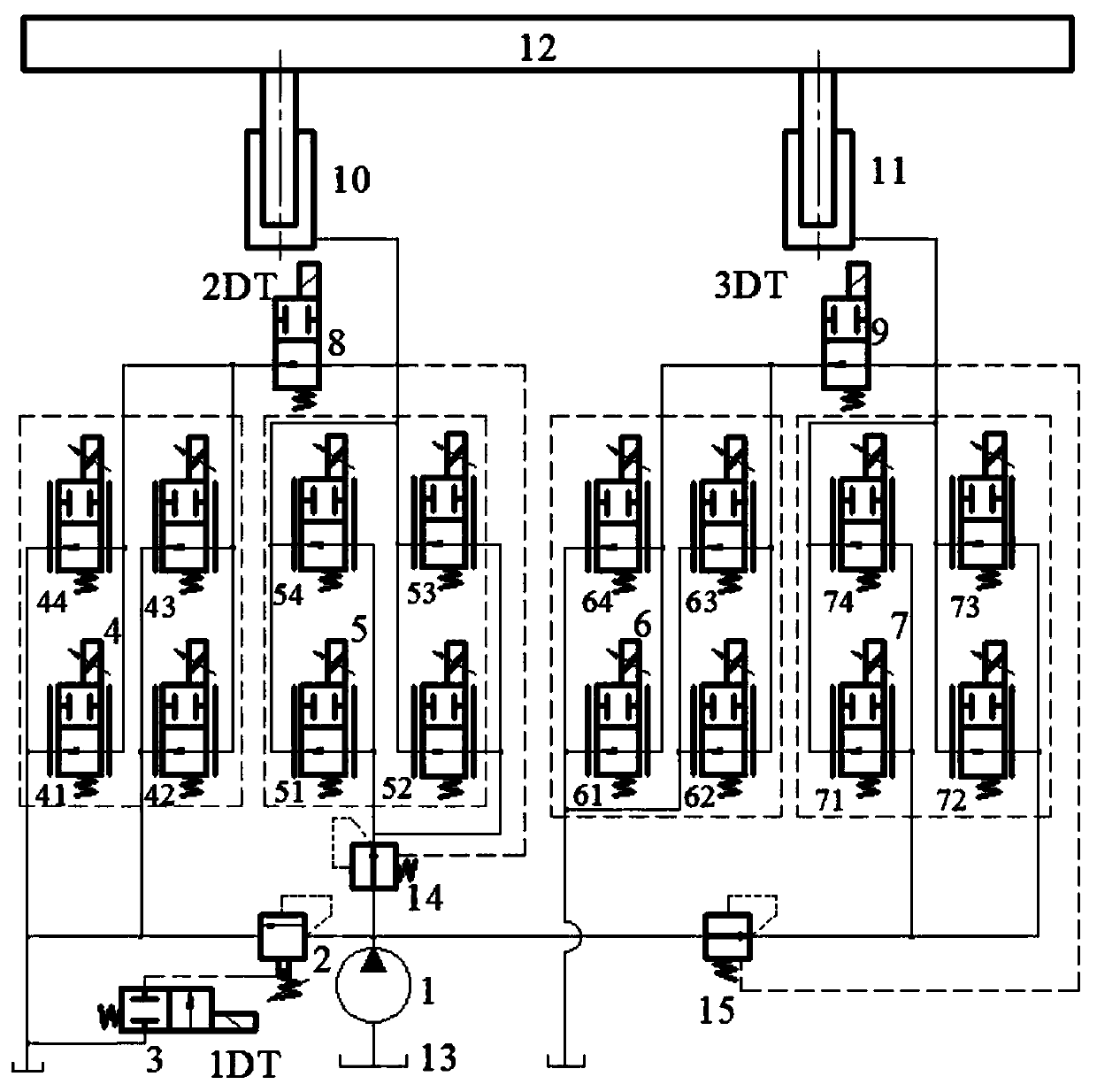

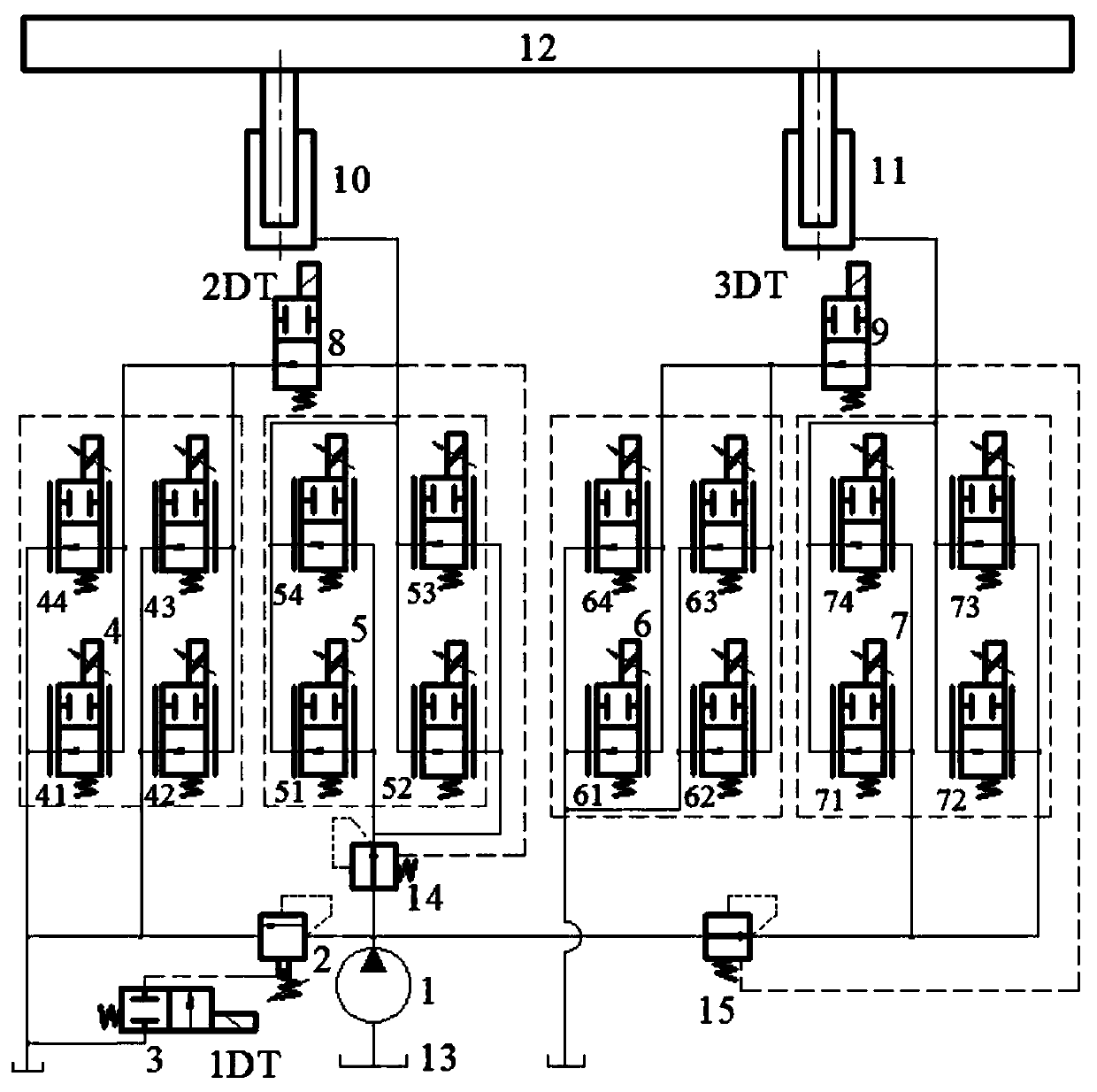

[0020] The embodiment of the present invention provides a large hydraulic press movable beam plunger type leveling hydraulic system, such as Figure 1-2 As shown, a large-scale hydraulic press movable beam plunger type leveling hydraulic system includes a movable beam 12, a first leveling plunger cylinder 10, a second leveling plunger cylinder 11, a first two-position two-way solenoid valve 3. The second 2-position 2-way solenoid valve 8 and the third 2-position 2-way solenoid valve 9. The first 2-position 2-way plug-in proportional valve island 4, the second 2-position 2-way plug-in proportional valve island 5, the third Two-position two-way plug-in proportional valve island 6, fourth two-position two-way plug-in proportional valve island 7, proportional overflow valve 2, hydraulic pump 1, four first Leveling plunger cylinder 10 and the second leveling plunger cylinder 11, the plunger ends of the first leveling plunger cylinder 10 and the second leveling plunger cylinder 11 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com