Tooth profile modification design method and system for cycloid gear of RV speed reducer

A technology of cycloidal gear and design method, which is applied in the direction of belt/chain/gear, instrument, calculation, etc., can solve the problems of no comprehensive consideration of manufacturing error and low transmission accuracy of cycloidal gear, so as to improve motion accuracy and tooth surface load The effect of uniform distribution and prolonged precision life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

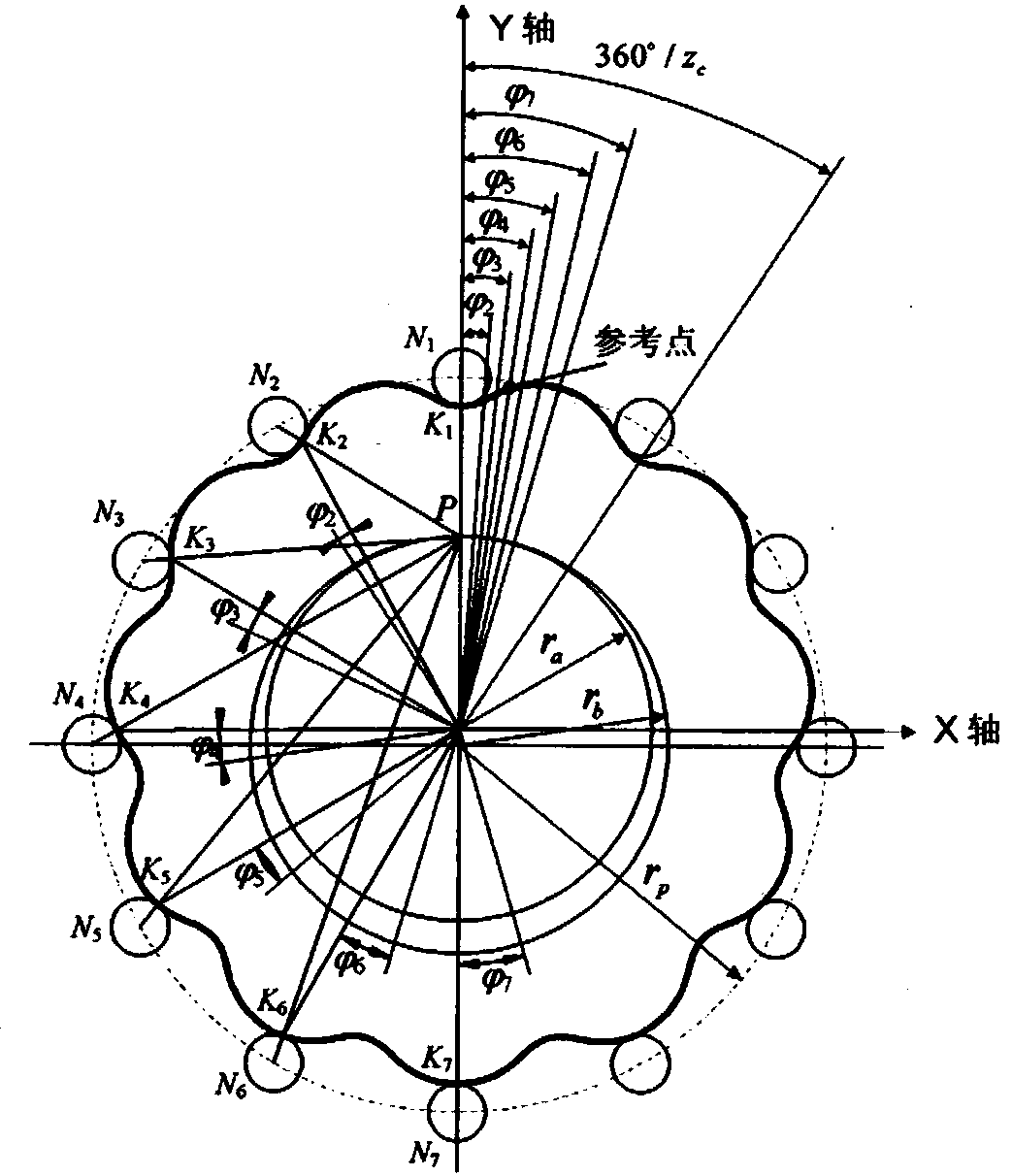

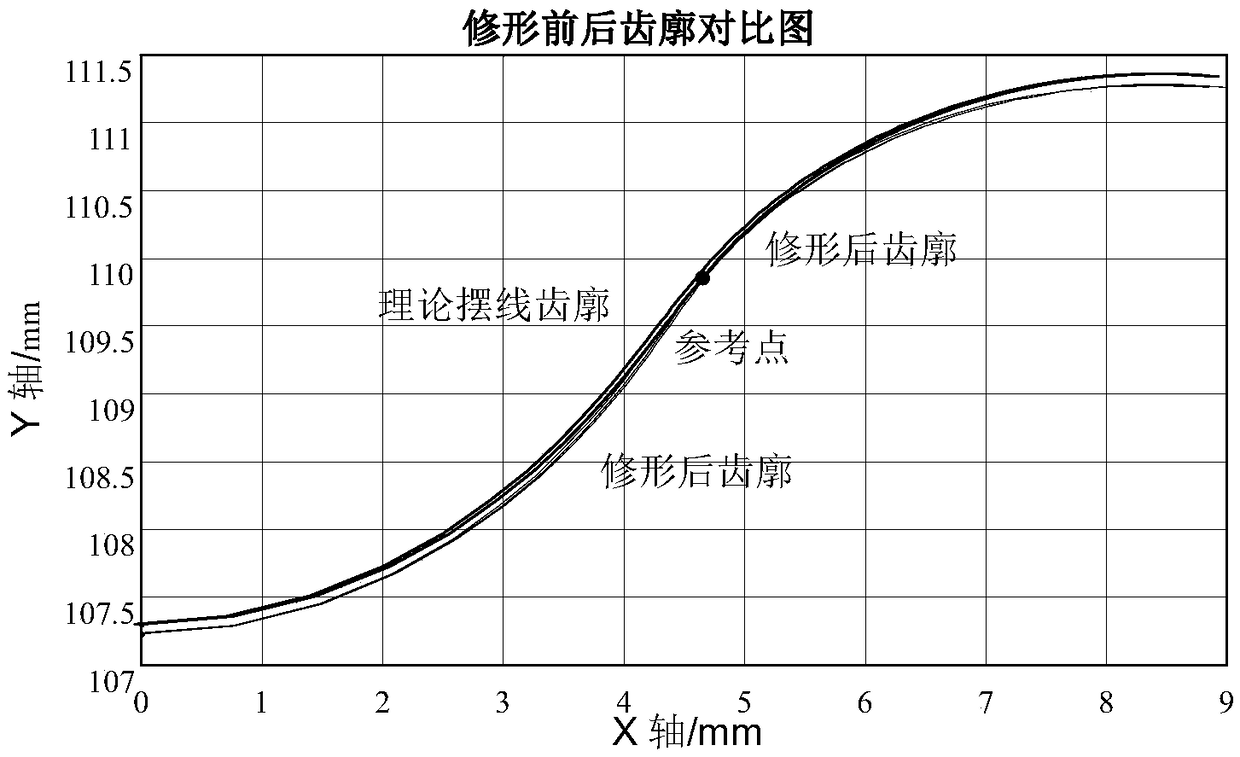

[0025] The RV reducer targeted by the present invention is as figure 1 shown, where pin teeth N 1 -N 7 Both are meshed with the cycloid wheel, and the meshing points are K 1 -K 7 , P is the meshing node of the cycloid, PK 1 -PK 7 are the normals of each meshing point, are the meshing phase angles of each meshing point, r p Pin tooth center circle radius. The present invention proposes a modified design method for the RV reducer, which defines a reference point in the radial direction of the cycloidal gear, and the reference point is a point where the modified tooth profile coincides with the theoretical cycloidal tooth profile , the theoretical cycloid tooth profile is modified at the non-reference point of the tooth profile, and the modification amount along the radial direction of the cycloid gear is gradually increased away from ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com