A model test strain brick sensor processing platform and its operation method

A model test and sensor technology, applied in the direction of electric/magnetic solid deformation measurement, electromagnetic measurement device, etc., can solve the problems of high defect rate and low efficiency of strain brick sensor, etc., achieve convenient welding, improve labor efficiency, and ensure personnel safety Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

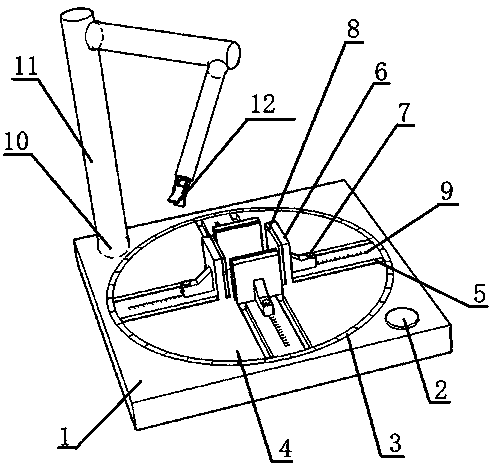

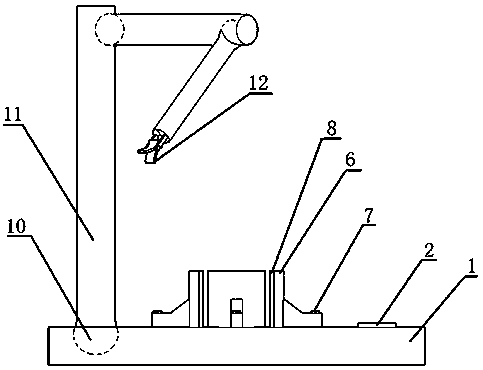

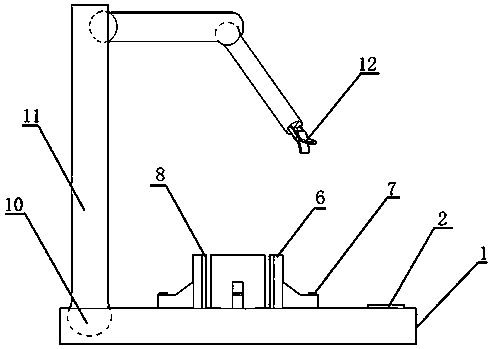

[0033] The present invention provides a model test strain brick sensor processing platform. In order to make the purpose, technical solution and effect of the present invention clearer and clearer, the specific implementation of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0034] Such as Figure 1~Figure 4 As shown, a model test strain brick sensor processing table of the present invention is mainly composed of a base 1, a turntable lock key 2, an angle score line 3, a turntable 4, a slide rail 5, a splint 6, a splint lock key 7, a splint gasket 8, Scale 9, universal ball 10, rotating arm 11 and cable clip 12 form.

[0035] The base 1 is a bottom plate of a processing table made of stainless steel. Rubber anti-skid pads are installed at the four corners of the base 1 to maintain the stability of the processing table. There is a cylindrical opening in the center of the base, and there is a rotating bearing inside for ins...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com