Machine tool fixture

A machine tool fixture and machine base technology, which is applied in the direction of clamping, manufacturing tools, metal processing machinery parts, etc., can solve the problems of accumulative error of machine base rework positioning, product collision damage, and inability to detect the exact size of the machine base from its center, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The core of the present invention is to provide a machine tool fixture, which can realize the positioning and clamping of the workpiece, and can meet the needs of workpiece processing and detection, reduce the detection error of the workpiece, and improve the processing accuracy and manufacturing efficiency.

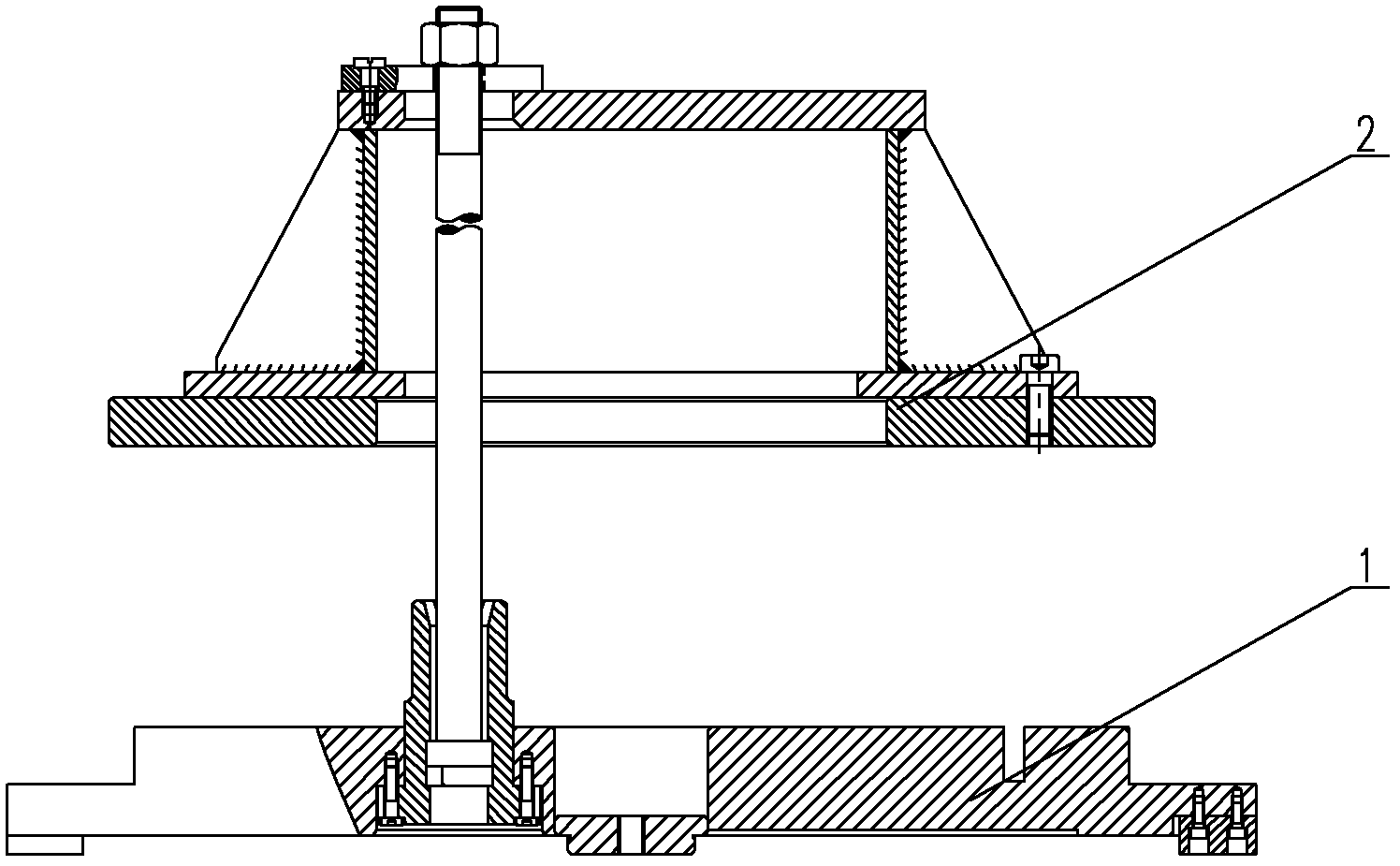

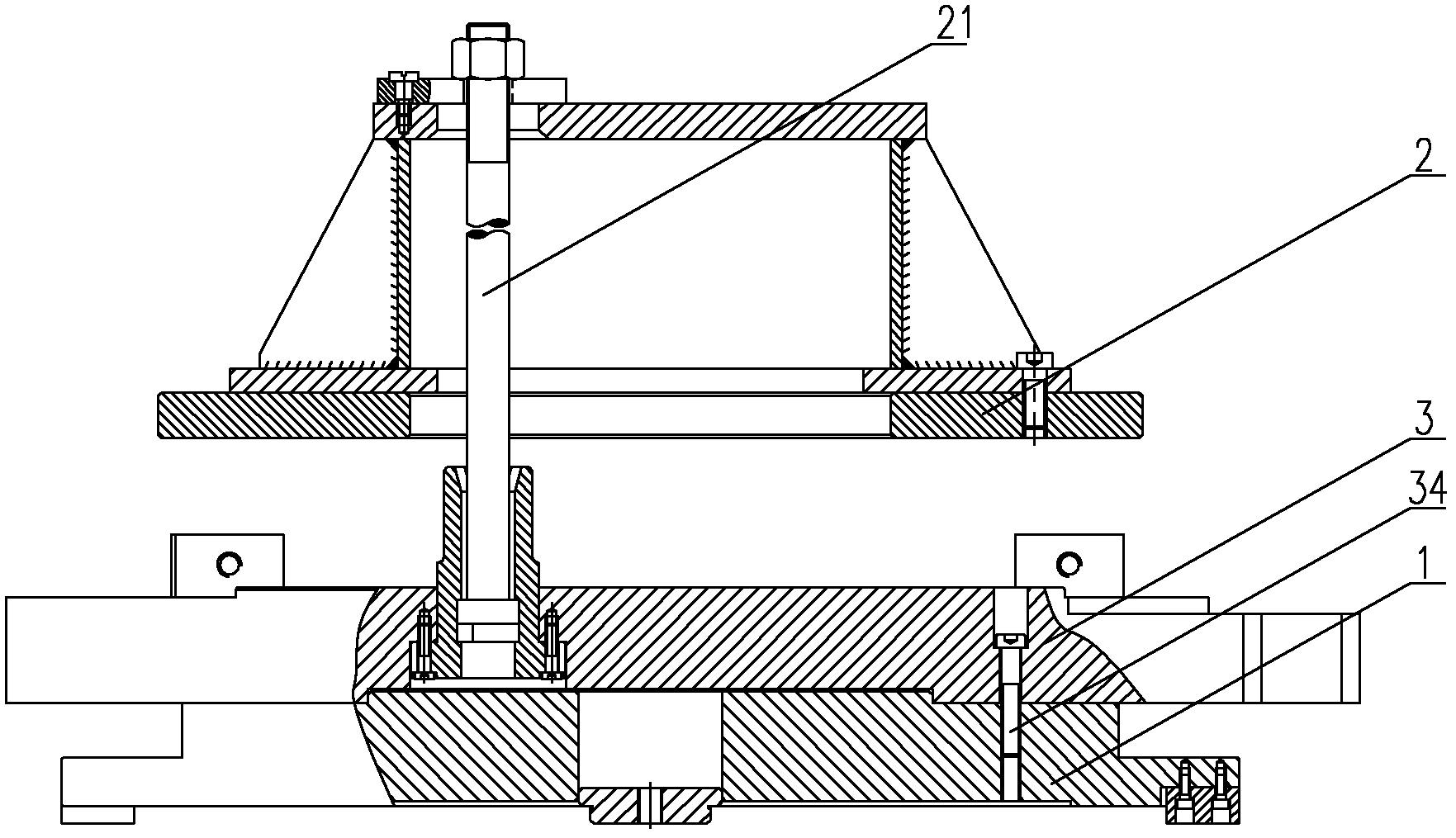

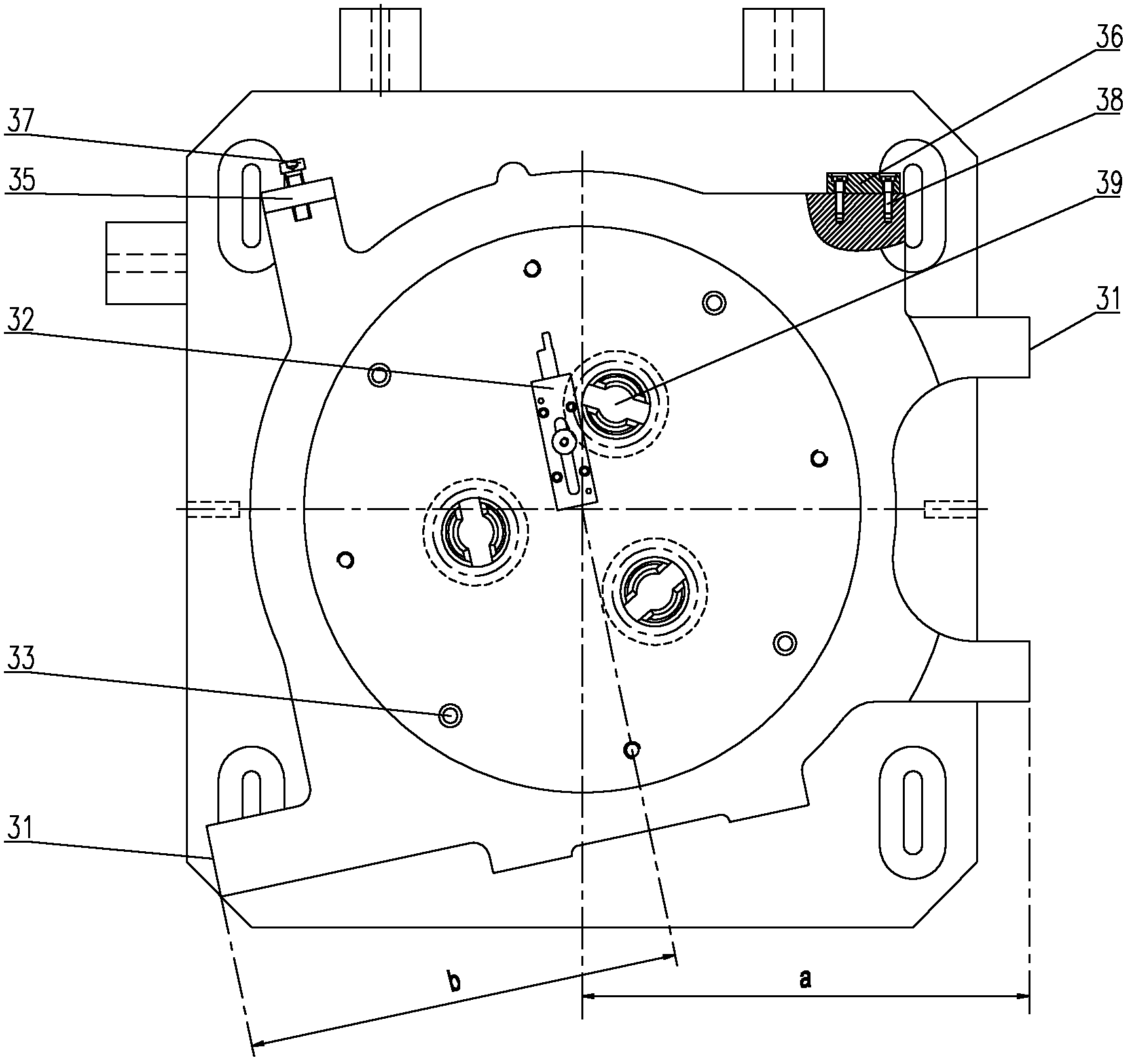

[0031] Please refer to figure 2 and image 3 , figure 2 It is a front view of a specific embodiment of the machine tool fixture provided by the present invention; image 3 for figure 2 top view.

[0032] In a specific embodiment, such as figure 2 and image 3 As shown, the present invention provides a machine tool fixture, which includes a base plate 1, a positioning plate 3 and a pressing device 2, the base plate 1 is used to support the workpiece, the pressing device 2 is used to fix the workpiece, and the positioning plate 3 is arranged on the base plate 1 Between the clamping device 2, the positioning plate 3 provides a detection reference plane 31 f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com