Four-ridge horn antenna and processing method thereof

A four-ridge horn and processing method technology, which is applied to antennas, waveguide horns, electrical components, etc., can solve the problems affecting the electrical performance and technical indicators of the antenna, the complex structure of the four-ridge horn antenna, and large processing and assembly errors. The effect of electrical performance and technical indicators, simple structure, and small processing and assembly errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

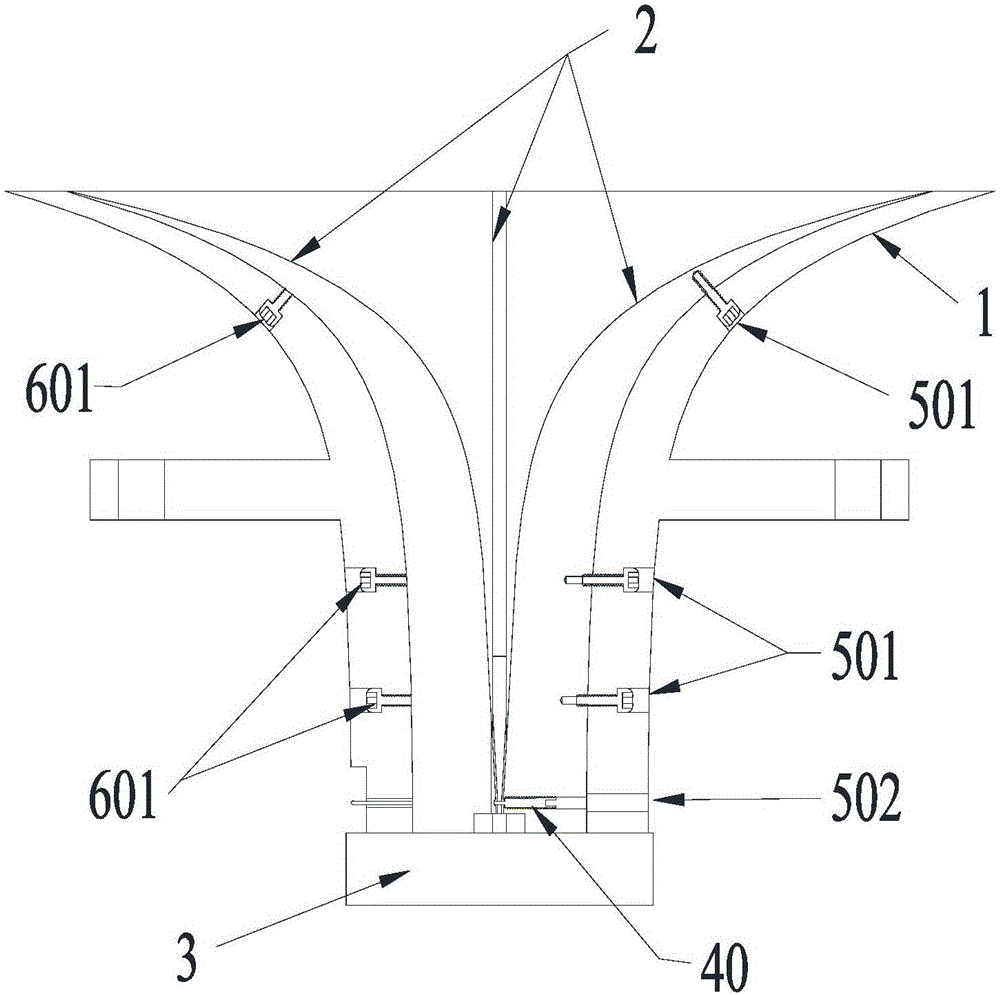

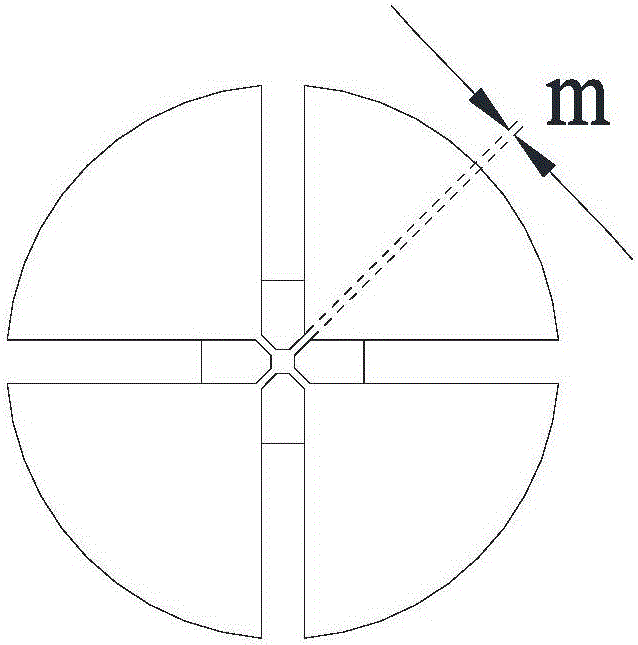

[0035] Below with the accompanying drawings ( Figure 4-Figure 9) to illustrate the present invention.

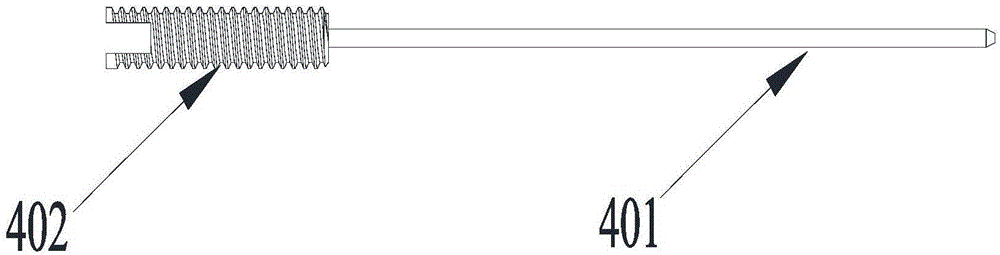

[0036] The present invention relates to a four-ridge horn antenna, such as Figure 4 , Figure 5 and Figure 6 As shown, among them, Figure 4 It is a schematic cross-sectional structure diagram of the four-ridge horn antenna of the present embodiment, Figure 5 yes Figure 4 right side view of the , Figure 6 for Figure 4 The perspective view of the horn main body in , the four-ridge horn antenna includes a horn main body 1, four ridges 2, a probe 4 and a short circuit board 3, and the four ridges 2 are evenly spaced in turn and are circumferentially arranged in the inner cavity of the horn main body 1 on, and if Figure 6 As shown, the four ridges 2 and the speaker main body 1 are integrally formed. Preferably, the four ridges 2 and the speaker main body 1 can be integrally formed by an electric discharge machining process, and the four ridges 2 can be cut by a c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com