Manual lifting adjustment device with double pawl driving and brake block interchangeability

A technology of lifting adjustment and brake blocks, which is applied in the direction of movable seats, can solve the problems of unreliable meshing, hidden dangers of reliability and safety, and error-prone assembly, so as to reduce the shape and weight, improve work reliability, The effect of improving the qualified rate of products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

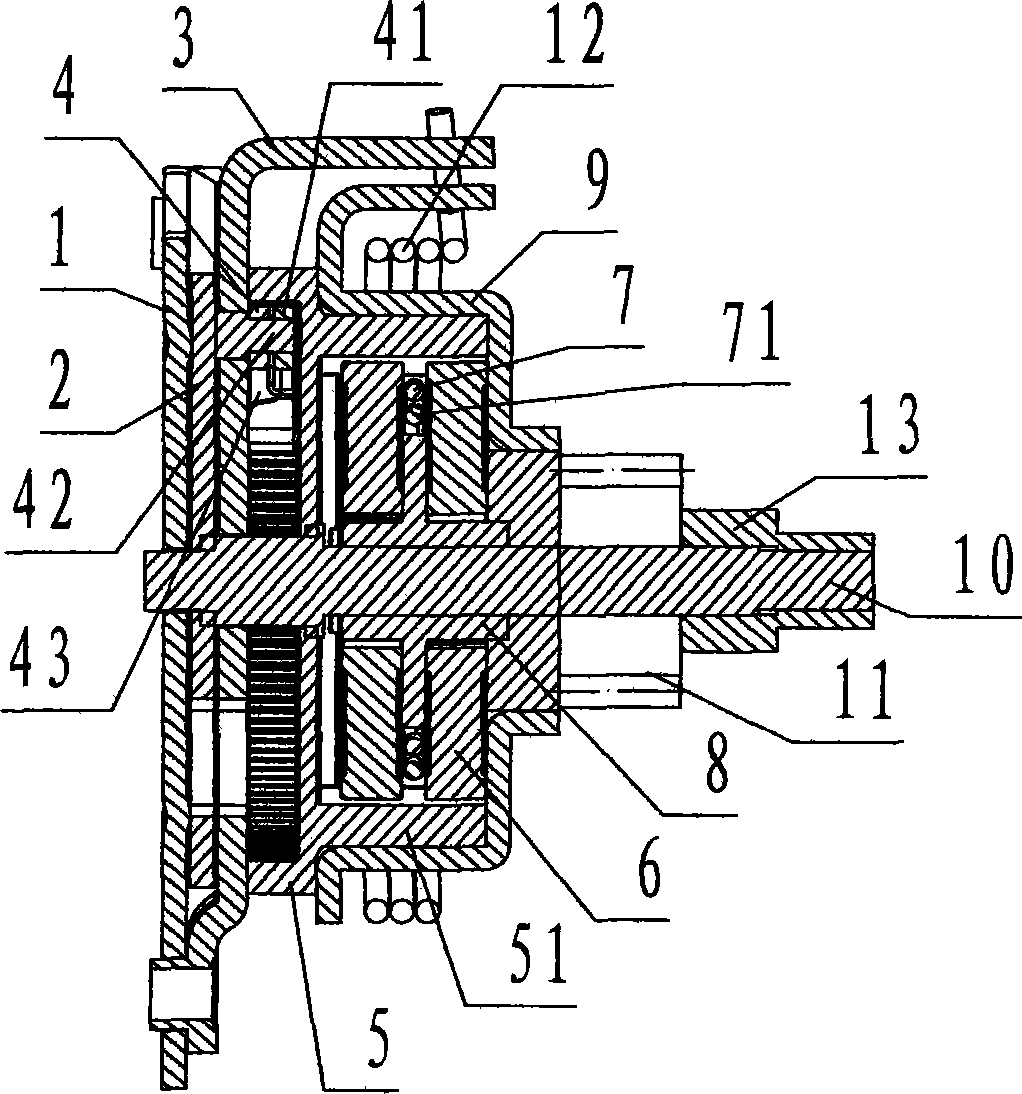

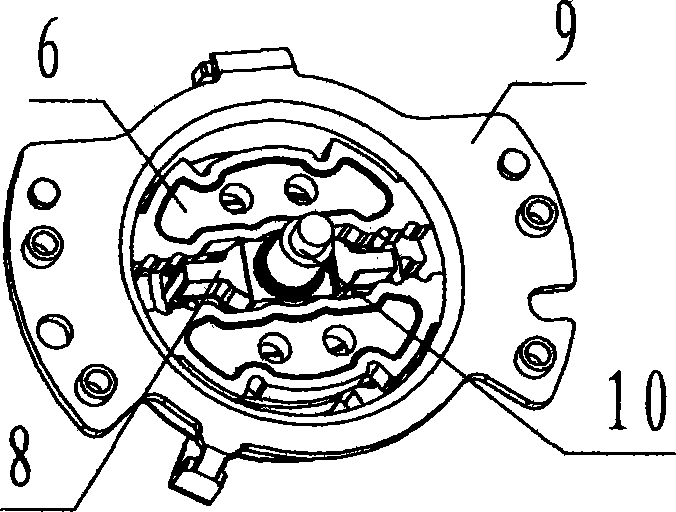

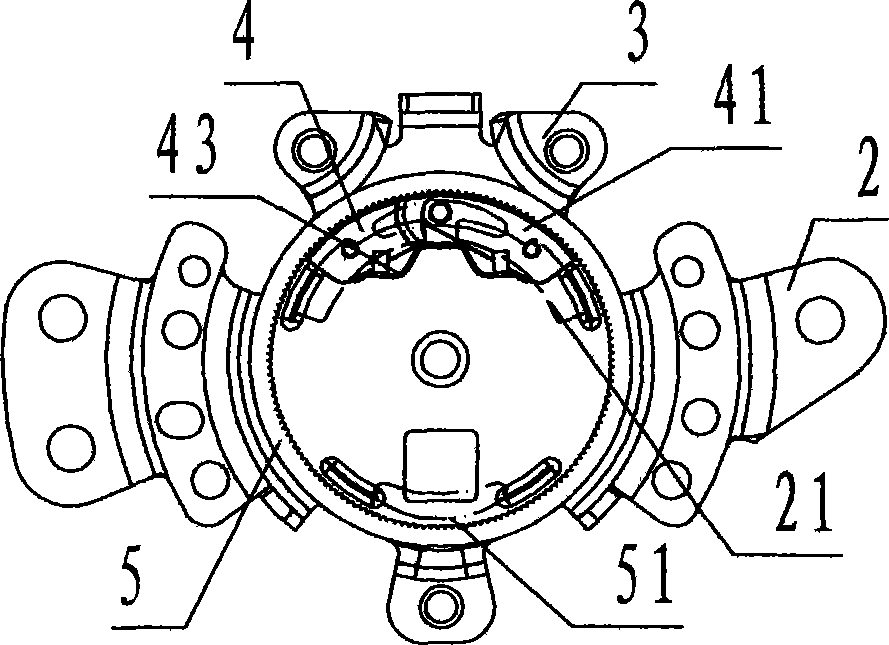

[0043] refer to Figure 1 to Figure 6 , a manual lifting adjustment device with interchangeable double pawl transmission and brake blocks of the present invention, including a handle plate 1, a mounting plate 2, a rotating plate 3, a left pawl 4, a right pawl 41, an internal tooth dial Disk 5, brake block 6, A circlip 7, B circlip 71, transmission cam 8, housing 9, central shaft 10, output gear 11, return spring 12, end sleeve 13, wherein: the handle plate 1 is It is a triangular steel plate member used to connect handles during application; the center of the handle plate 1 is provided with a circular through hole called the first middle hole;

[0044] Described mounting plate 2 is the disc-shaped steel plate stamping component that is used for fixed installation purpose during application; There is a circular through hole called the second middle hole; with the second middle hole as the center of the circle, the upper and lower center lines are symmetrical, and the upper par...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com