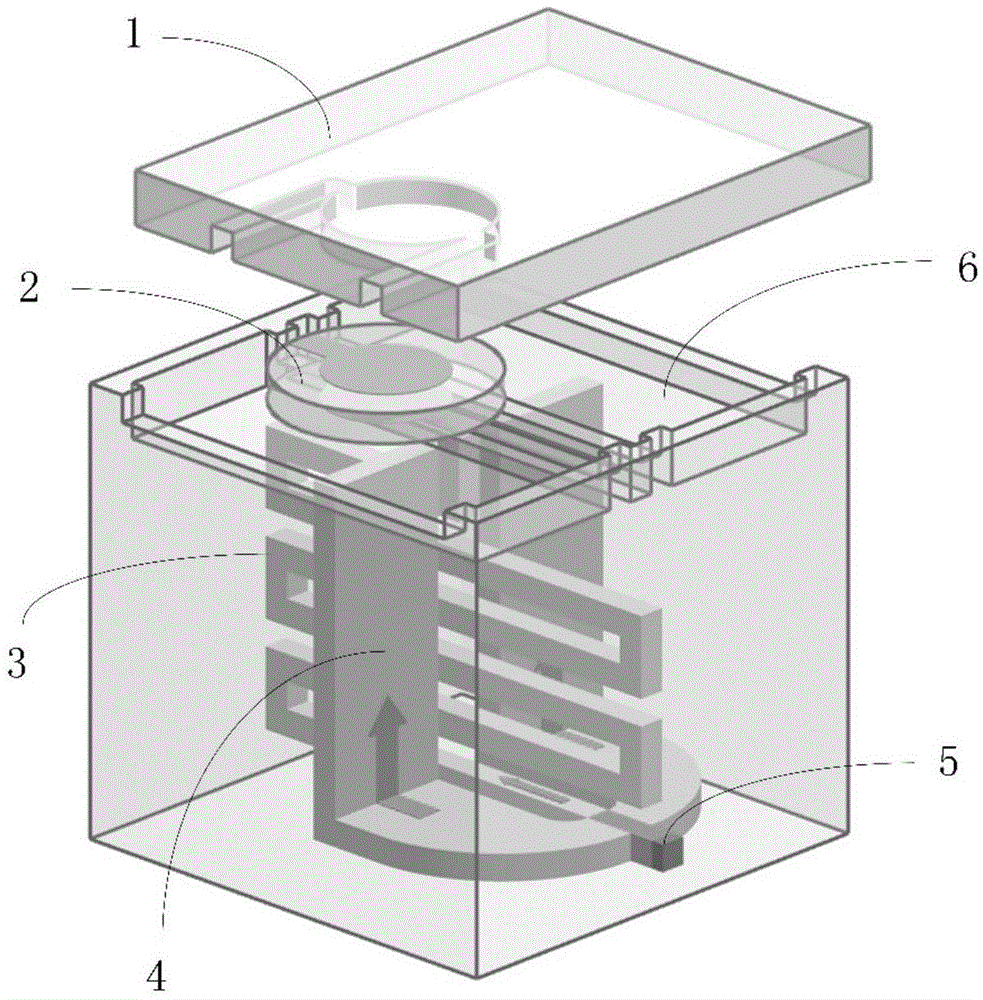

Virtual impactor and particle separation and concentration detecting device and method based on 3D printing technology

A concentration detector and 3D printing technology, which is applied in separation methods, dispersed particle separation, chemical instruments and methods, etc., can solve problems such as increasing pressure difference, and achieve the effects of maintaining calibration, working stably, and high resolution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

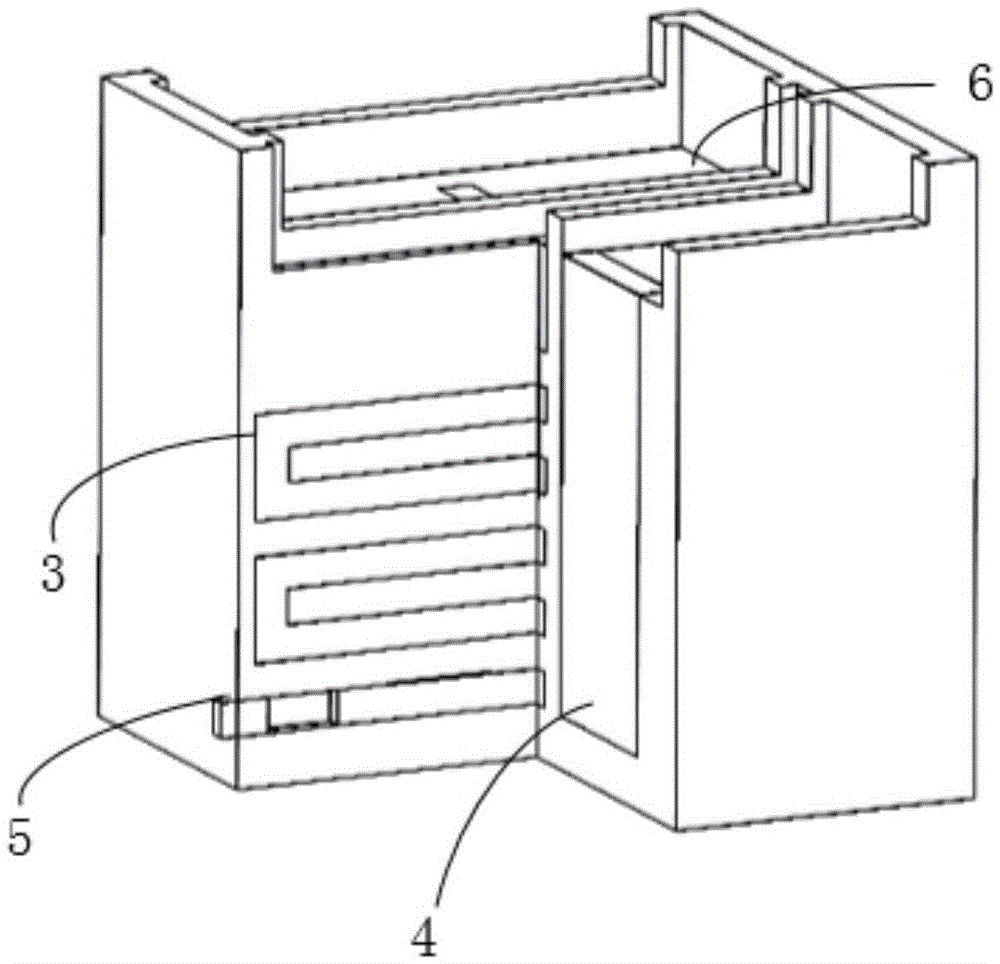

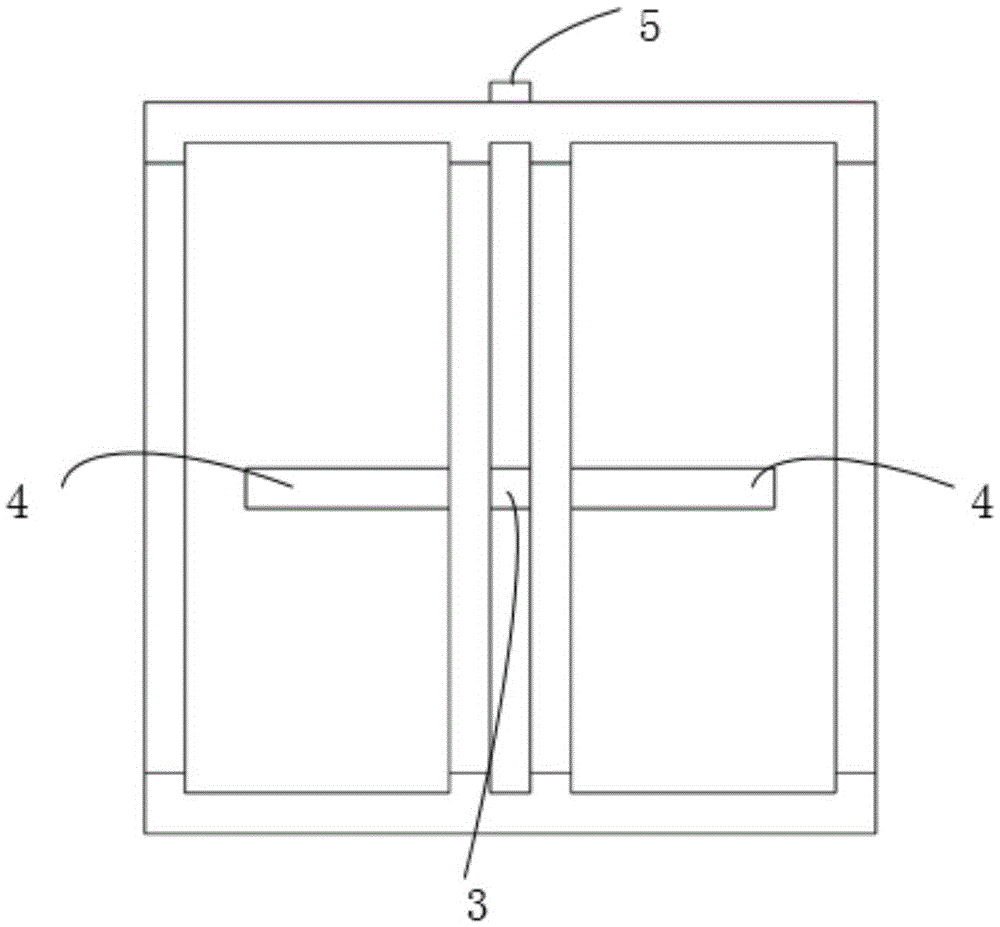

Method used

Image

Examples

Embodiment

[0049] In this example, the cigarette smoke environment was used as the gas in the PM formation chamber, and the QCM was replaced with a glass slide. The fine particulate matter PM2.5 in the atmosphere contains various substances such as sulfur oxides, nitrogen oxides, and polycyclic aromatic hydrocarbons, while cigarette burning smoke contains nitrogen oxides, aromatic hydrocarbons, and other substances, which are similar to the types of PM2.5 in the atmosphere , so the study first considered and used the cigarette smoke environment as the gas in the PM forming chamber for experiments. The device adopts the above-mentioned virtual impactor and particle separation and concentration detector based on 3D printing technology. In the experiment, light the cigarette, connect one end of the cigarette with a dropper, put the burning end of the cigarette into the PM forming chamber, gently squeeze the dropper to give the necessary gas flow for the cigarette to burn, and squeeze the ci...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com