Isosceles micro prism and method for manufacturing mold

A microprism and isosceles technology, applied in manufacturing tools, milling machine equipment details, optics, etc., can solve the problems of large increase and decrease, unfavorable retroreflection applications, etc., to avoid assembly errors, ensure integrity, guarantee, etc. The effect of deep cutting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

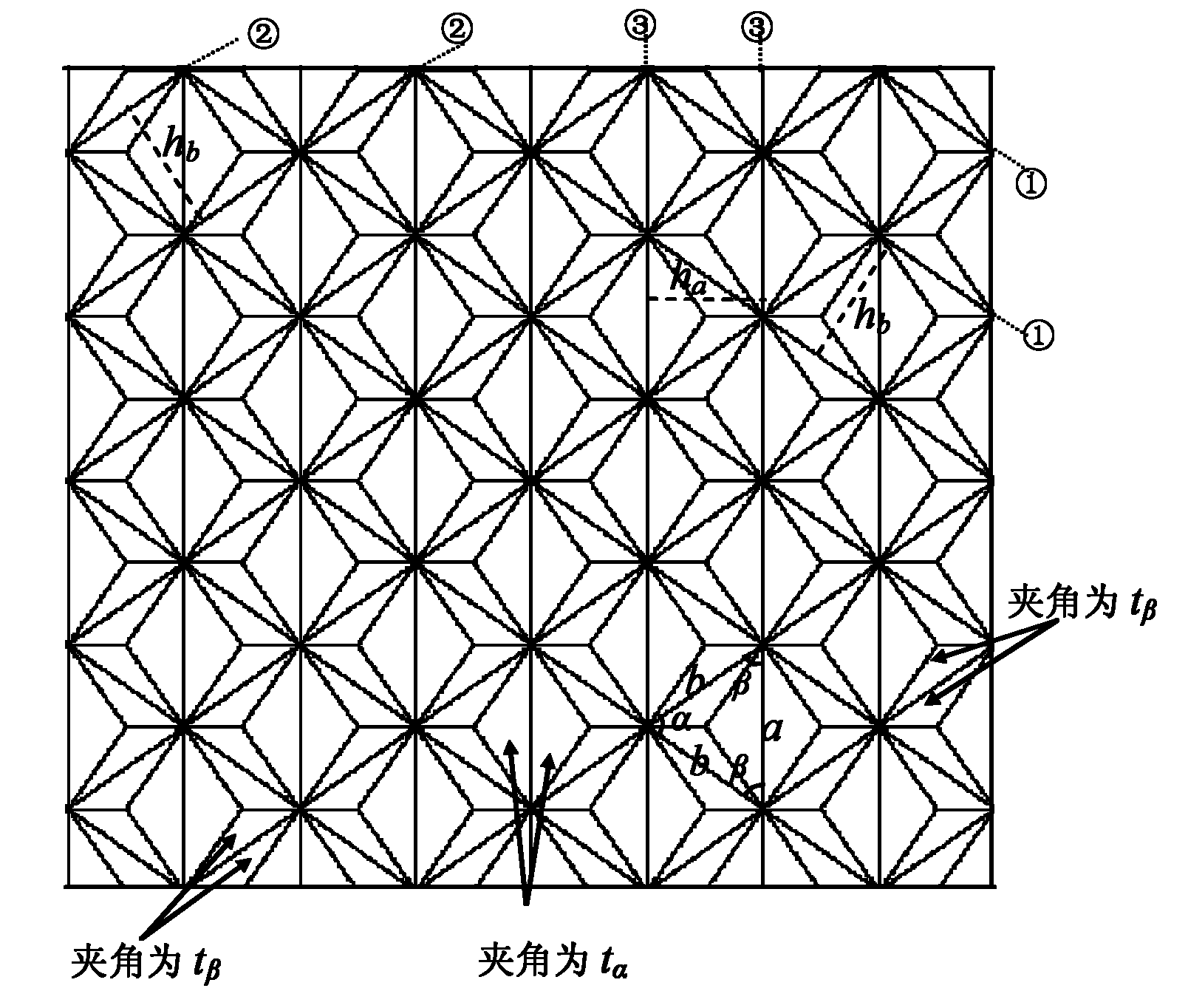

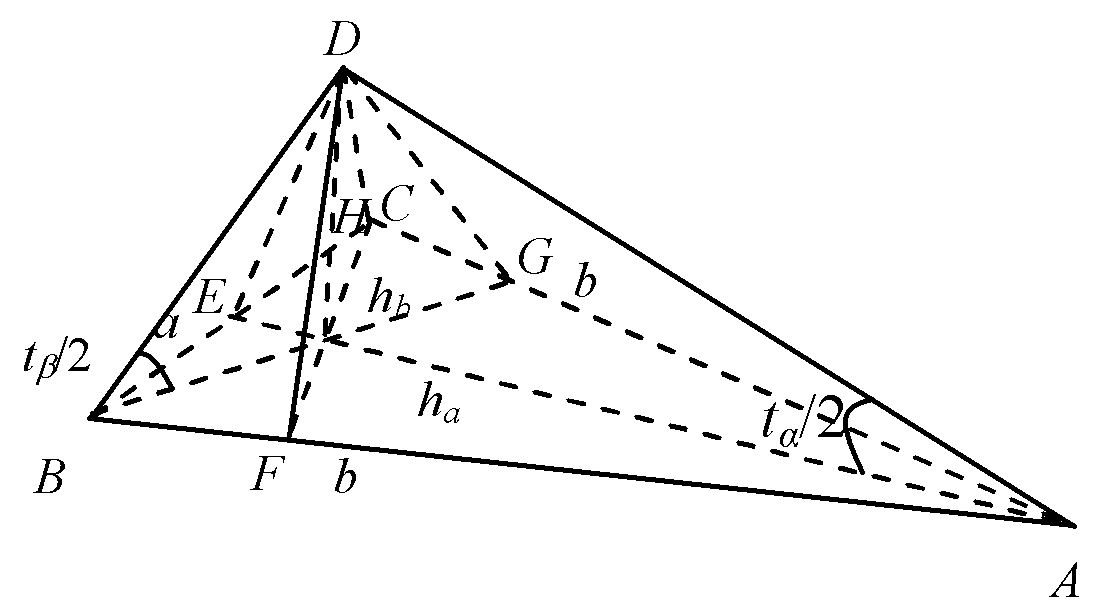

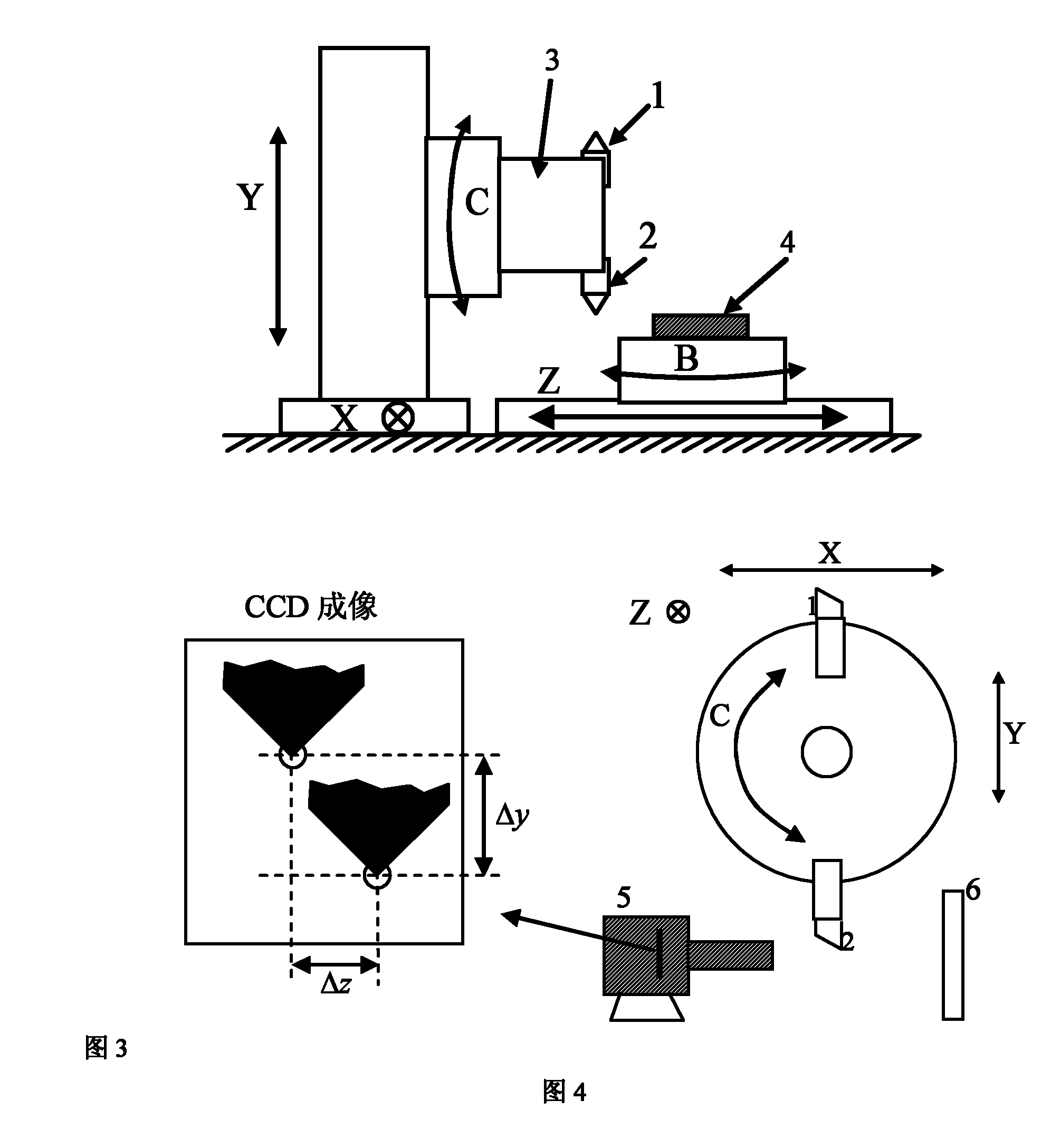

[0021] The invention relates to a microprism structure design and processing method whose bottom surface is an isosceles triangle. The designed microprism structure is easy to use diamond cutting or "fly-cutting" processing method for ultra-precision machining, and the obtained "convex" mold can be formed by hot pressing, injection molding or other molding methods to generate " Concave" solid microprism products. figure 1 It is the microprism structure of the present invention. The microprism unit is a tetrahedron, the bottom surface of the tetrahedron is an isosceles triangle, and the side lengths of the three sides are: bottom a, waist b, the triangle angle angle corresponding to the bottom is α, and the triangle angle angle corresponding to the waist is β; One of the three sides is an isosceles triangle, and the other two are the same hypotenuse triangles, and the three sides intersect perpendicularly at the apex of the structure. There are two different angles between th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com