Hall thrustor capable of realizing self cleaning of polluted membrane of discharge channel and self cleaning method of Hall thrustor

A Hall thruster and discharge channel technology, applied in chemical instruments and methods, cleaning methods and appliances, thrust reversers, etc., can solve problems such as assembly errors, influence of experimental results, easy change of vacuum conditions of test devices, etc., to avoid The effect of assembly error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

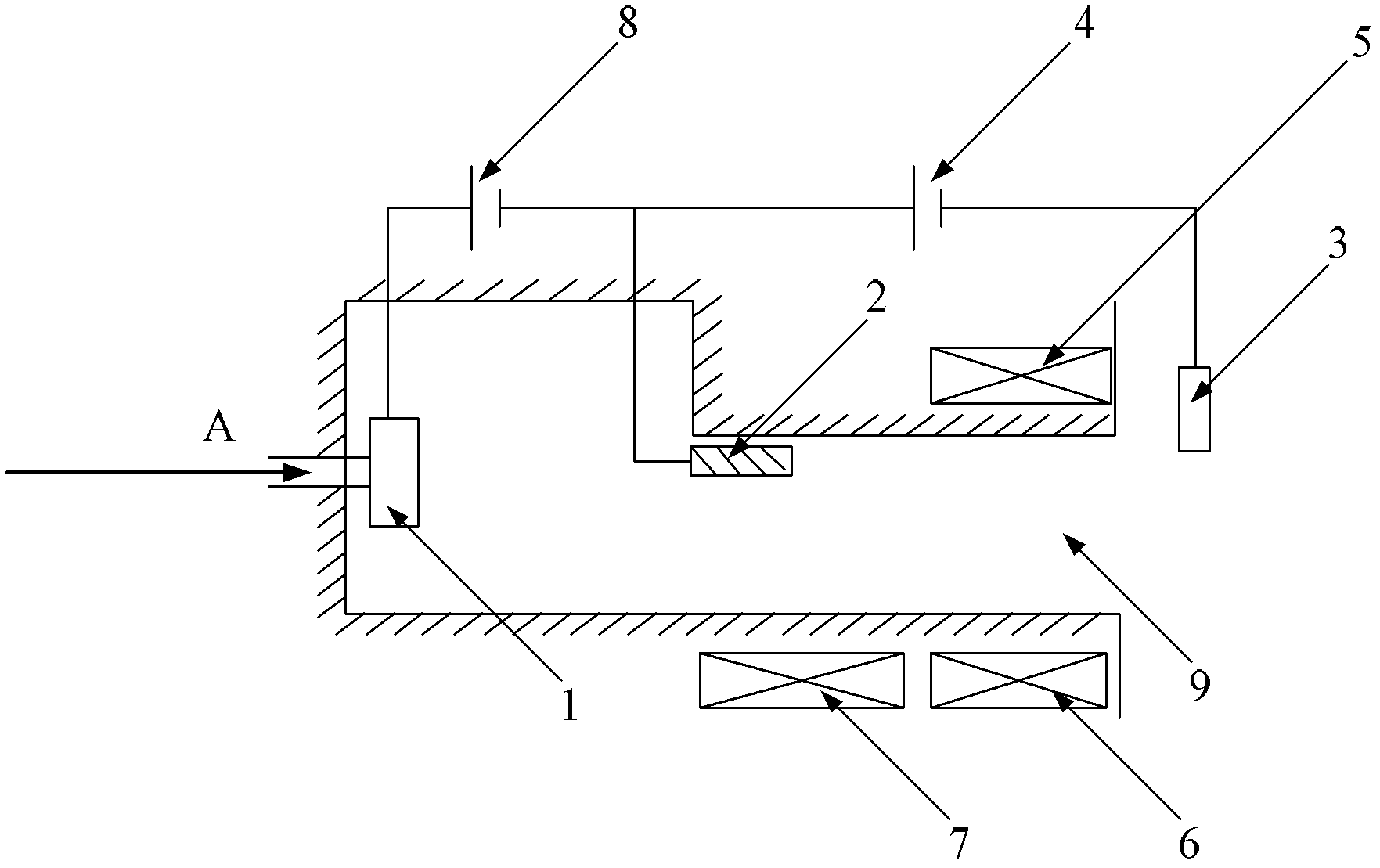

[0011] Specific implementation mode one: combine figure 1 Describe this embodiment mode, the Hall thruster that can self-clean discharge channel contamination film described in this embodiment mode, it comprises gas distributor 1, anode 2, cathode 3, discharge power supply 4, outer coil 5, inner coil 6, additional Coil 7 and discharge channel 9; the gas distributor 1 and anode 2 are arranged inside the discharge channel 9, the gas distributor 1 is arranged at the propellant A injection port in the discharge channel 9, the gas distributor 1 The gas inlet is communicated with the propellant A injection port; the anode 2 is arranged in the middle of the discharge channel 9; the cathode 3 is arranged at the outlet of the discharge channel; the anode 2 is connected to the positive pole of the discharge power supply 4, and the cathode is connected to the discharge power supply The negative pole of 4; the outer coil 5 and the inner coil 6 are symmetrically arranged on both sides of t...

specific Embodiment approach 2

[0012] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the self-cleaning power supply 8 adopts a constant voltage power supply of 30-50V. Other compositions and connection methods are the same as those in Embodiment 1.

specific Embodiment approach 3

[0013] Specific embodiment three: the self-cleaning method of the Hall thruster that can self-clean the discharge channel polluted film of this embodiment as described in specific embodiment two, it is completed by the following steps:

[0014] Step 1: Pre-ionization generates self-cleaning ions; under the action of self-cleaning power supply 8, the electrons in the discharge channel 9 will move from the anode 2 to the gas distributor 1, and obtain kinetic energy from the self-cleaning pre-ionization electric field; The electrons moving from the anode 2 to the gas distributor 1 will collide with the atoms of the propellant A injected from the gas distributor 1 to generate ionization and generate self-cleaning ions;

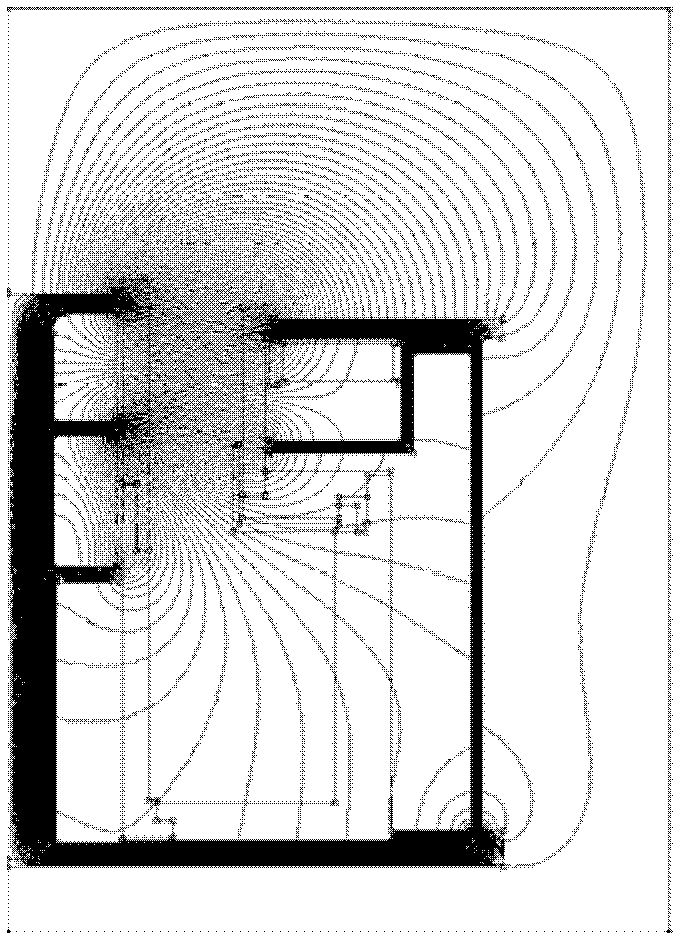

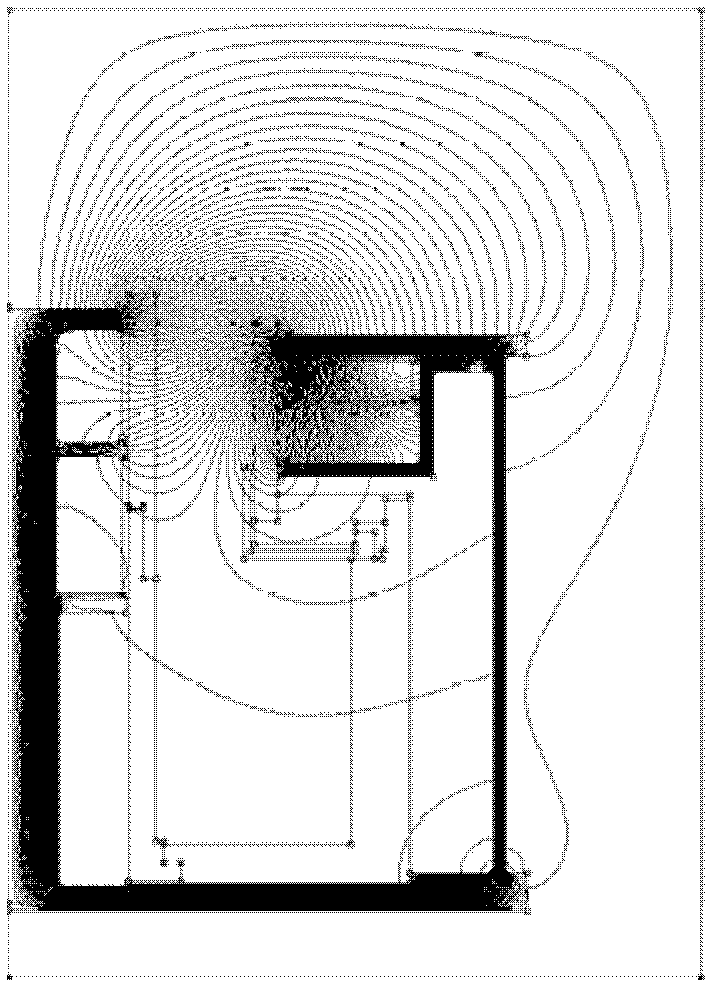

[0015] Step 2: The self-cleaning ions bombard the inner or outer wall of the discharge channel 9 under the action of the focusing magnetic field or divergent magnetic field formed by the outer coil 5, the inner coil 6 and the additional coil 7, and remove the inner...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com